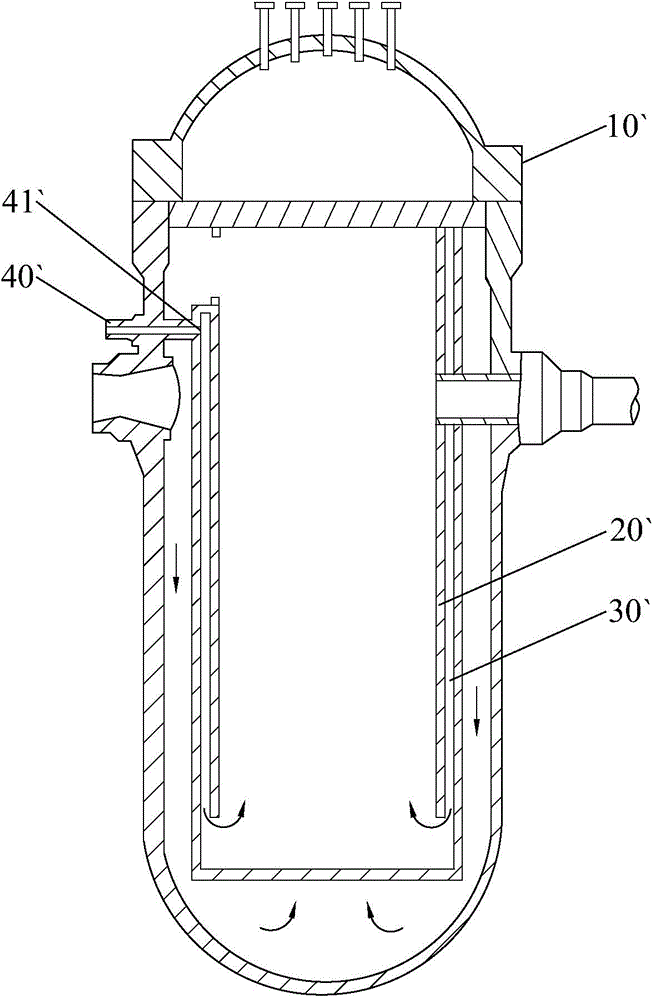

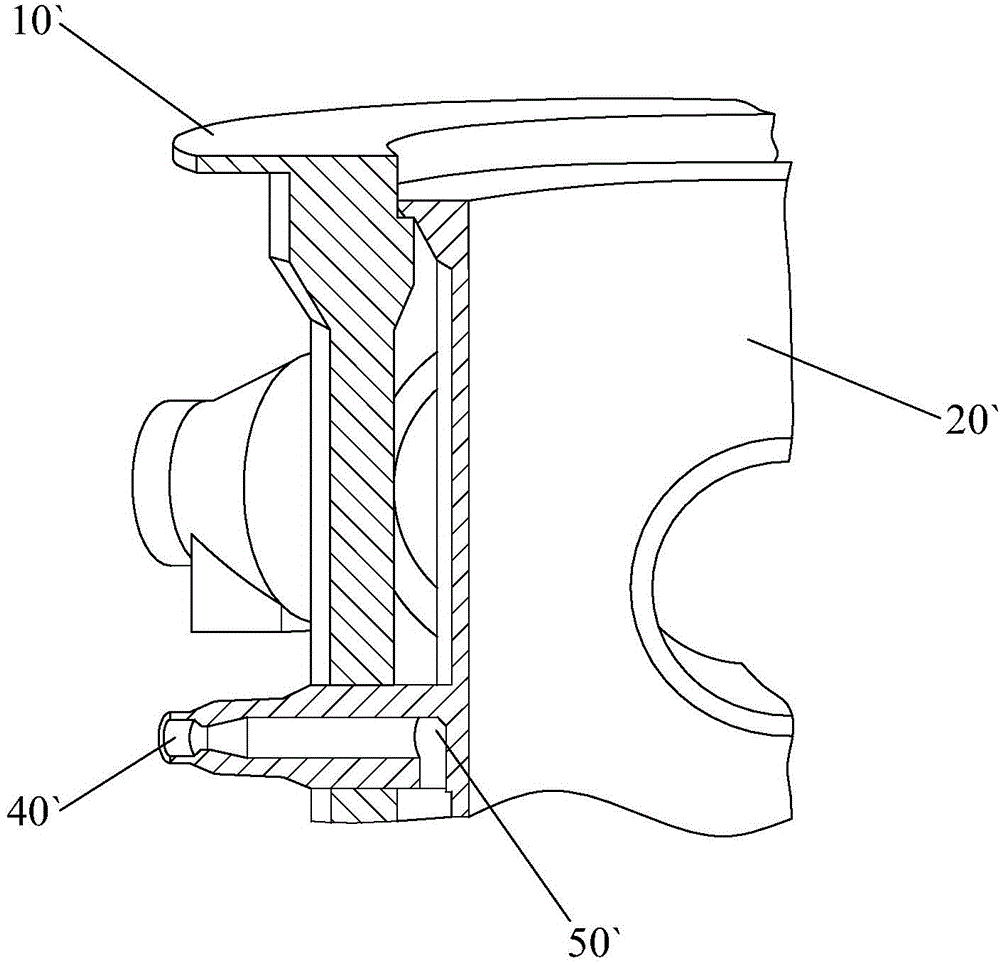

Nuclear reactor direct safety injection system

A nuclear reactor, direct technology, applied in the direction of reactors, nuclear engineering, nuclear power generation, etc., can solve the problems of large thermal shock, increase of diversion devices, safety injection effect and poor anti-bypass flow, etc., to achieve good flow conductivity, control and ease the effect of the upgrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

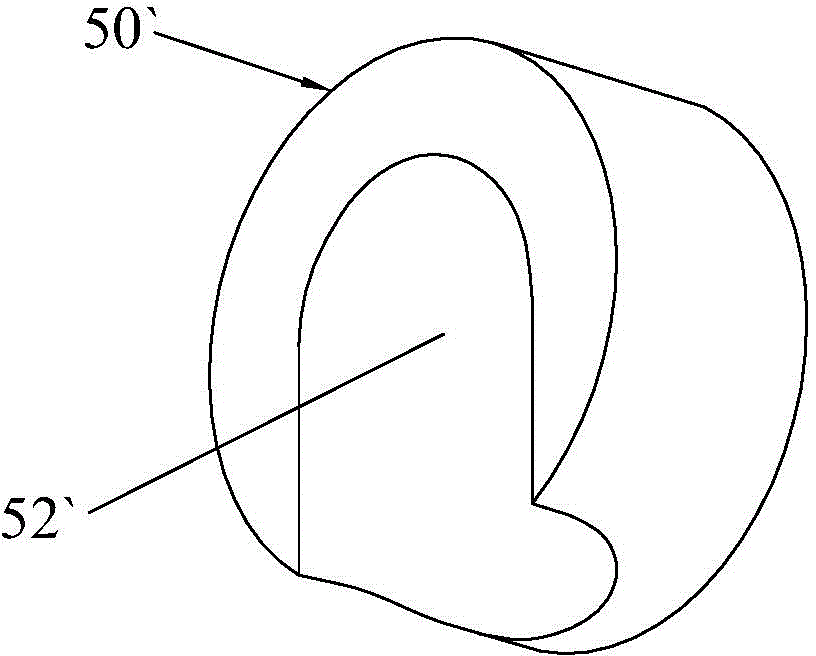

[0046] combine Figure 7-8a As shown, preferably, the distribution holes 62 are evenly distributed with the center of the flow distribution member 60 as the center O.

[0047] combine Figure 7-8a As shown, preferably, the distribution holes 62 on the same diameter with the center O of the flow distribution member 60 as the center are the same.

[0048] combine Figure 7-8aAs shown, preferably, the distribution hole 62 of the flow distribution member 60 gradually becomes smaller from bottom to top; that is, the size of the distribution hole 62 on each level is the same, and the distribution holes 62 of different levels are vertically smaller. Multiple rows of holes are formed on the top, and the distribution holes 62 in the upper row are smaller in diameter than the distribution holes 62 in the lower row.

[0049] In order to further improve the efficiency and uniformity of the cooling liquid delivered by the direct injection pipe, combined with Figure 5-Figure 8a As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com