Surface processing method of large-size sputtering target material

A sputtering target and surface treatment technology, applied in milling machine equipment details, metal processing mechanical parts, maintenance and safety accessories, etc., can solve the problems of low liquid penetration efficiency, weak penetration ability, poor heat dissipation and lubrication effect, etc. , to improve the effect of heat dissipation and lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The inventors of the present invention found that in the existing large-size sputtering target surface treatment technology, if ordinary cutting fluid is used to infiltrate in the form of liquid penetration during cutting, its penetration ability is not strong, resulting in poor heat dissipation and lubrication effects , the surface flatness and smoothness of the sputtering target are poor.

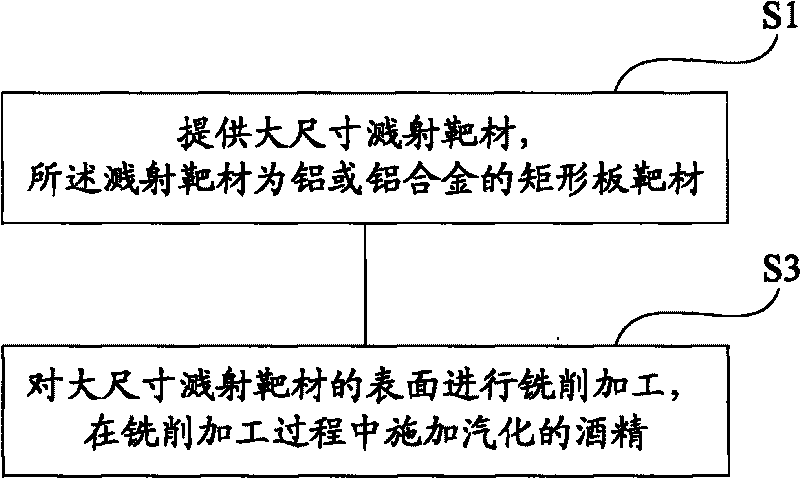

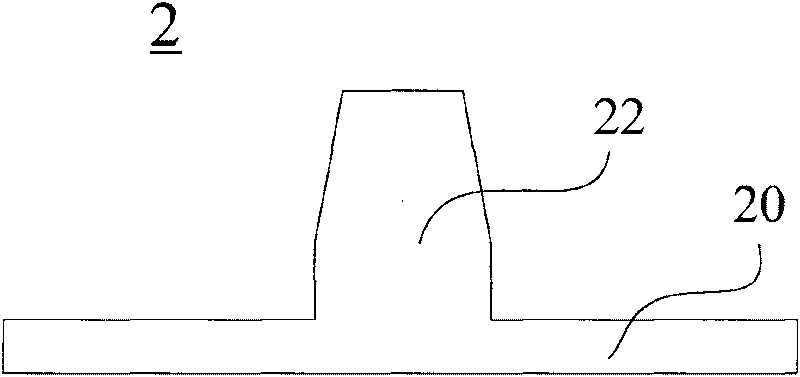

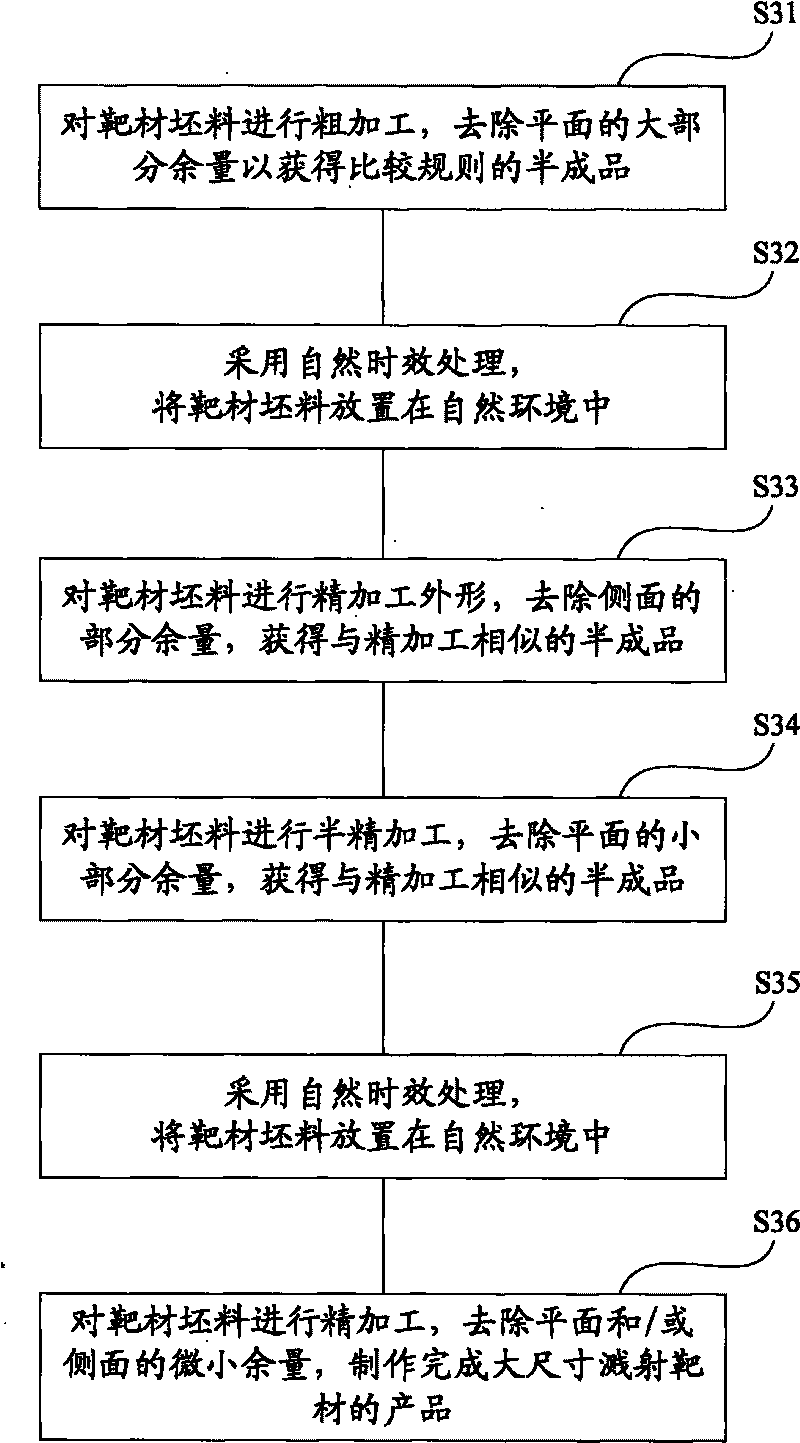

[0022] In view of this, the present invention provides a surface treatment method for a large-size sputtering target, the method comprising: providing a large-size sputtering target, the sputtering target being aluminum or an aluminum alloy; The surface of the target is milled, and vaporized alcohol is used for cooling during the milling process. Utilizing the volatility of alcohol and infiltrating with vaporized vapor-liquid two-phase fluid, it has a better heat dissipation effect and improves the surface smoothness and smoothness of the sputtering target.

[0023] refer to figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com