Magnetic control K-TIG welding gun based on water-cooled permanent magnets

A permanent magnet and welding torch technology, applied in welding equipment, welding rod characteristics, arc welding equipment and other directions, can solve the problems of increasing arc restraint effect and penetration ability, small process window for qualified welding seam, unfavorable and stable penetration of small holes, etc. Achieve the effect of increasing penetration ability, avoiding demagnetization, and compact structure of the welding gun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

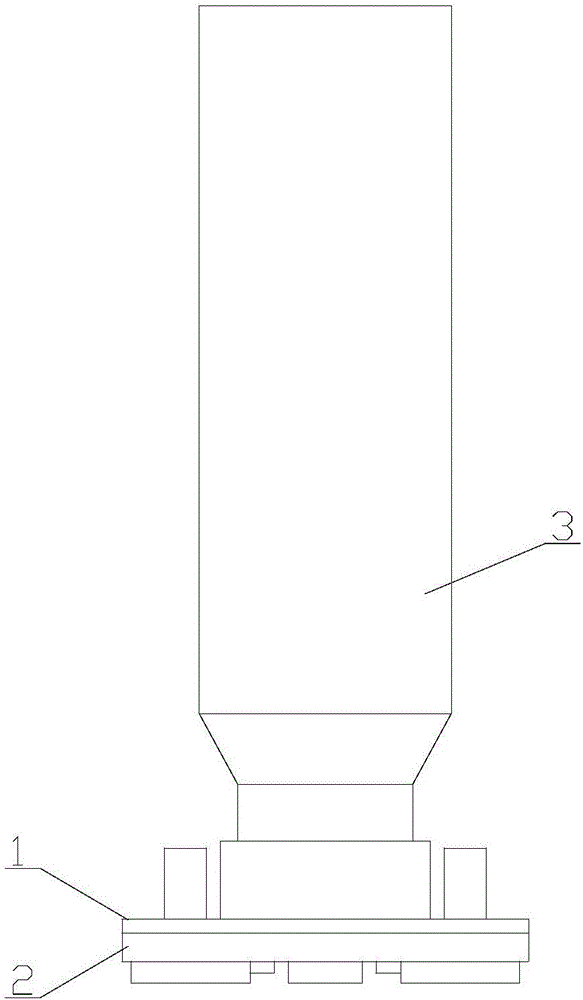

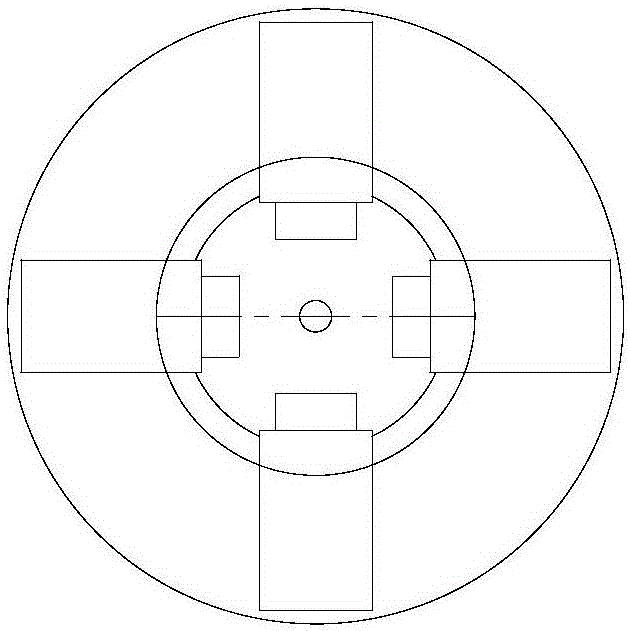

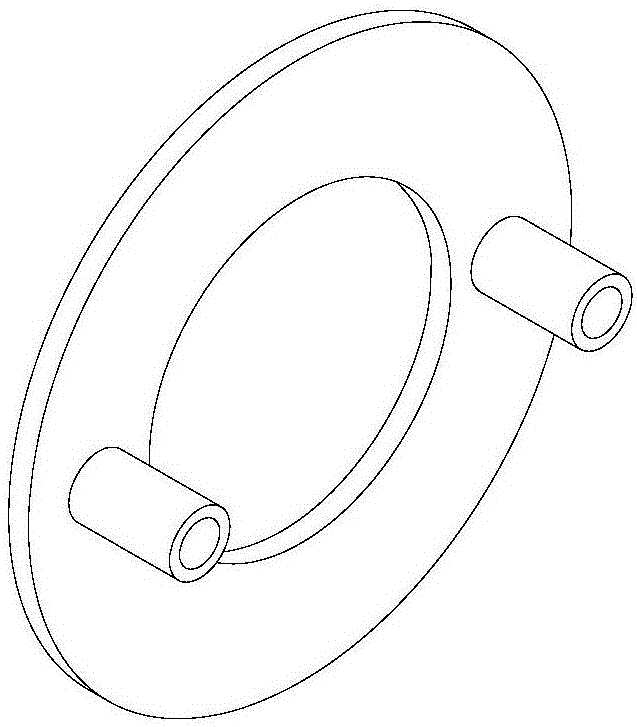

[0033] Such as figure 1 and figure 2 As shown, this embodiment provides a magnetically controlled K-TIG welding torch based on water-cooled permanent magnets, which mainly includes a cover 1 and a housing 2 connected to the lower part of the cover 1. The cover 1 and the housing 2 form a The closed space is fixed at the tip of the welding torch 1. Permanent magnets uniformly distributed in the radial direction are arranged in the closed space, and a water cooling device is arranged around the permanent magnets. In this way, the confinement effect and wear-through of the arc are increased when using multi-magnetic poles to construct a pointed magnetic field. Under the premise of improving the permeability, the purpose of cooling the permanent magnet in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com