Contact-type central water-discharging permanent magnet synchronous electric spindle

A central water outlet and permanent magnet synchronization technology, which is applied to large fixed members, metal processing machinery parts, maintenance and safety accessories, etc., can solve problems such as tool cooling, improve processing quality, power and torque, and improve tool cooling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

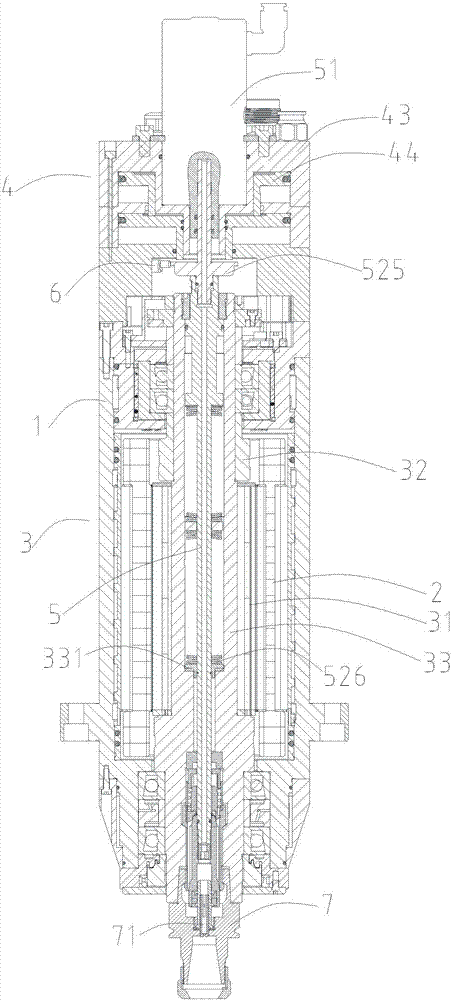

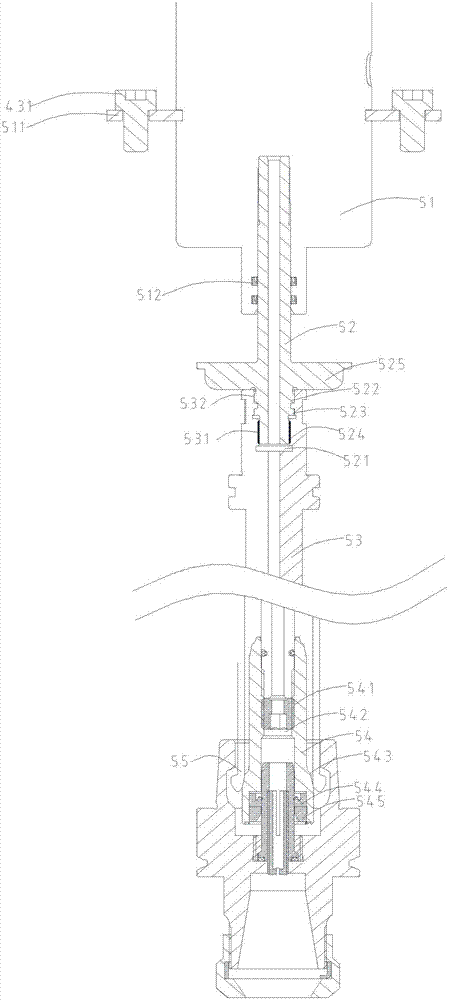

[0033] refer to figure 1 , a contact type central water outlet permanent magnet synchronous electric spindle, comprising a body 1, a stator 2, a permanent magnet shaft core assembly 3, a cylinder assembly 4, a central water outlet assembly 5 and a sensor 6;

[0034] The stator 2 and the permanent magnet shaft core assembly 3 are both arranged in the inner cavity of the body 1; the permanent magnet shaft core assembly 3 includes a permanent magnet rotor 31, an interaxial sleeve 32 and a shaft core 33; the permanent magnet rotor 31 is sleeved with a shaft core 33; The shaft sleeve 32 is arranged above the permanent magnet rotor 31;

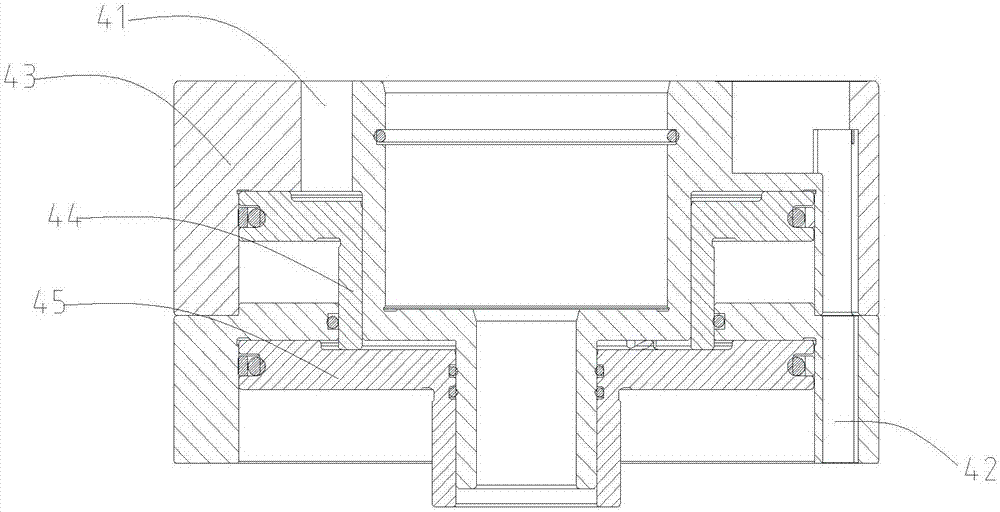

[0035] refer to figure 2 , the cylinder assembly 4 is arranged on the upper end of the body 1; the cylinder assembly 4 includes a first air passage 41, a second air passage 42, a cylinder top cover 43, a first piston 44 and a second piston 45; the cylinder top cover 43, the first piston 44 and the second piston 45 are pressed sequentially from to...

Embodiment 2

[0059] This embodiment is characterized in that: with reference to Figure 4 , A glue layer 34 is provided between the lower end surface of the permanent magnet rotor 31 and the shaft core 33; a gap 35 is provided between the interaxial sleeve 32 and the permanent magnet rotor 31; the rest of the structures and features are the same as those in Embodiment 1.

[0060] Since the permanent magnet rotor is magnetic, it will attract iron filings on the shaft core, especially embedded in the gap between the shaft sleeve and the permanent magnet rotor, which is difficult to remove. If the iron filings cannot be removed, the high-speed rotation of the spindle will throw the iron filings out, resulting in a shortened service life of the electric spindle. In order to solve this problem, the lower end surface of the permanent magnet rotor is glued and then installed on the shaft core to form a glue layer to prevent the embedding of iron filings; a 1mm gap is designed between the permanen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com