Cooling monitoring device and method for water lubricated bearing of propeller shaft

A technology for water-lubricated bearings and propeller shafts, which is used in bearing cooling, shafts and bearings, and transmission devices with synchronous propulsion components, etc., can solve the problem of non-compliance with environmental protection requirements, inability to observe the wear degree of water-lubricated bearings in real time, and easy leakage of lubricating oil. and other problems, to achieve the effect of prolonging the operation time of the ship, avoiding frequent docking and testing, and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

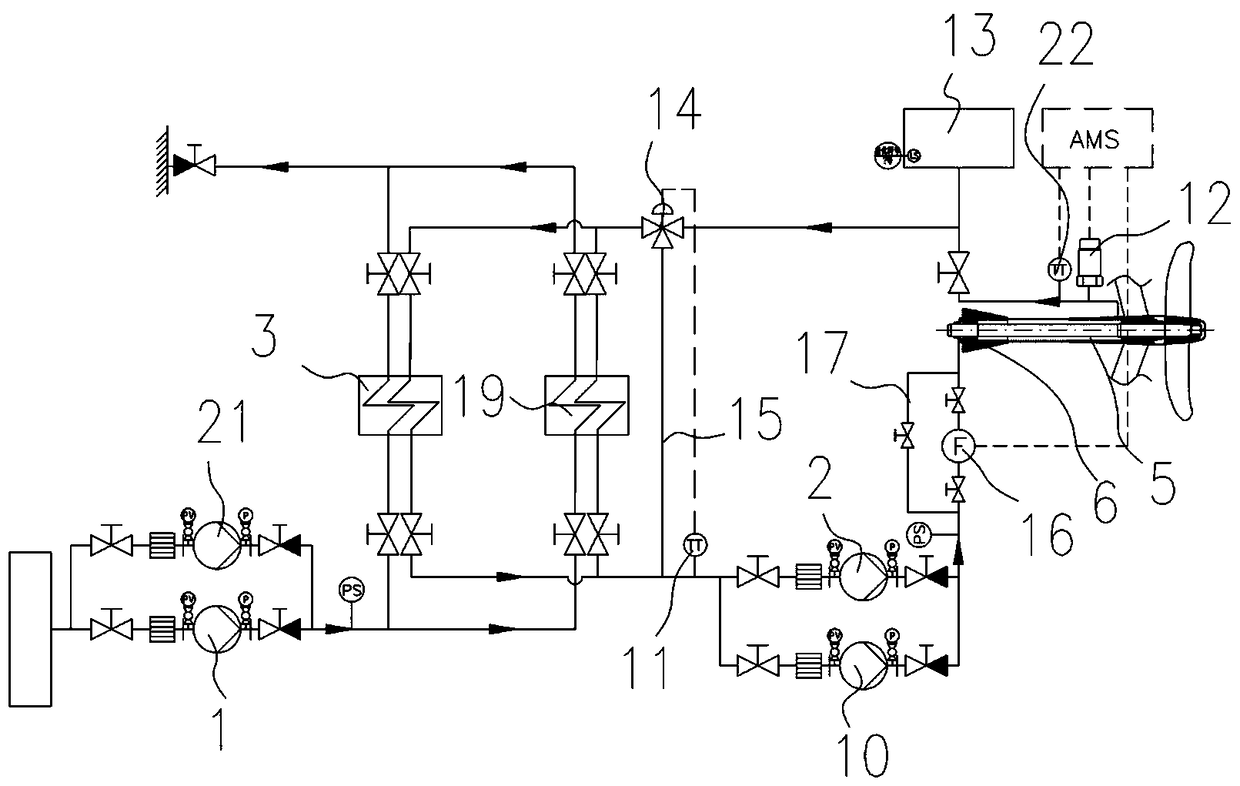

[0011] A cooling monitoring device for a water-lubricated bearing of a propeller shaft, such as figure 1 As shown, it includes a seawater cooling pump 1, a fresh water cooling pump 2 and a plate cooler 3; the water outlet of the fresh water cooling pump 2 communicates with the cooling channel on the water lubricated bearing 6 in the stern shaft lumen 5 through a pipeline, and the The water inlet of the fresh water cooling pump 2 communicates with the plate cooler 3 through a pipeline, the water inlet of the seawater cooling pump 1 communicates with the outside world through a pipeline, and the water outlet of the seawater cooling pump 1 communicates with the plate cooler 3 through a pipeline, The plate cooler 3 is also communicated with the outside world and the stern shaft cavity 5 through pipelines respectively, the seawater flowing into the plate cooler 3 from the sea water cooling pump 1 is discharged through the pipeline communicating with the outside of the plate cooler 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com