Narrow gap and deep groove welding head

A welding head and deep bevel technology, applied in welding equipment, welding accessories, welding connection methods, etc., can solve problems such as difficult to complete welding work, insufficient gas protection ability of welding head, and difficulty in ensuring welding safety of nuclear power products, etc. Achieve sufficient protection, flexible and sufficient gas protection, and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below in conjunction with the accompanying drawings, and the features and advantages of the present invention will become clearer and clearer along with these descriptions.

[0062] The word "exemplary" is used exclusively herein to mean "serving as an example, embodiment, or illustration." Any embodiment described herein as "exemplary" is not necessarily to be construed as superior or better than other embodiments. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

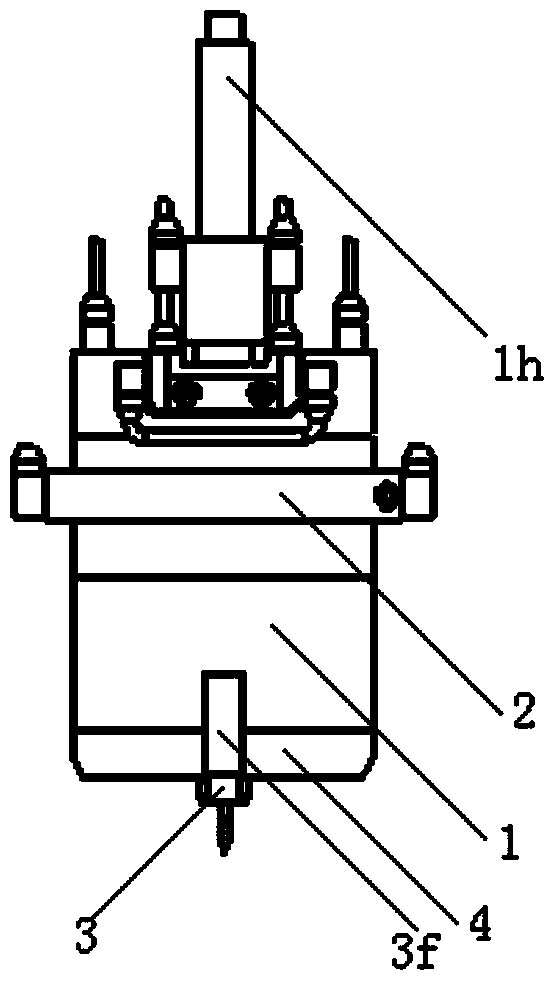

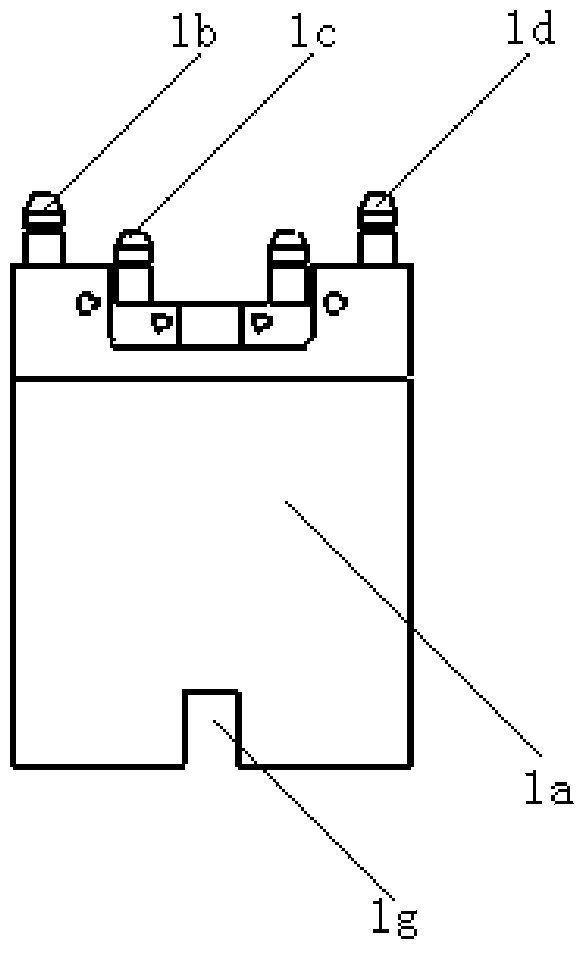

[0063] In a preferred embodiment of the present invention, such as figure 1 As shown, a narrow gap deep groove welding head is provided, which includes:

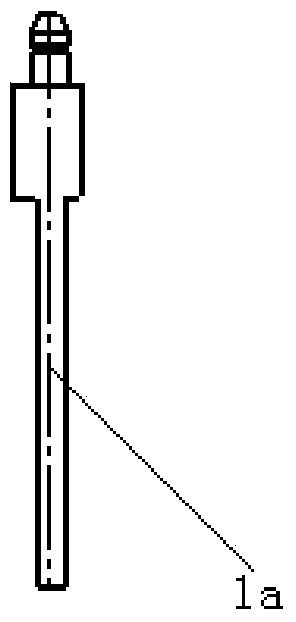

[0064] Welding head main body 1, primary shielding gas lens, tungsten electrode system 3, two secondary gas shields 2 and two secondary shielding gas lenses connected to the bottom thereof. Among them, the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com