Patents

Literature

74results about How to "Reduce cleaning dead angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

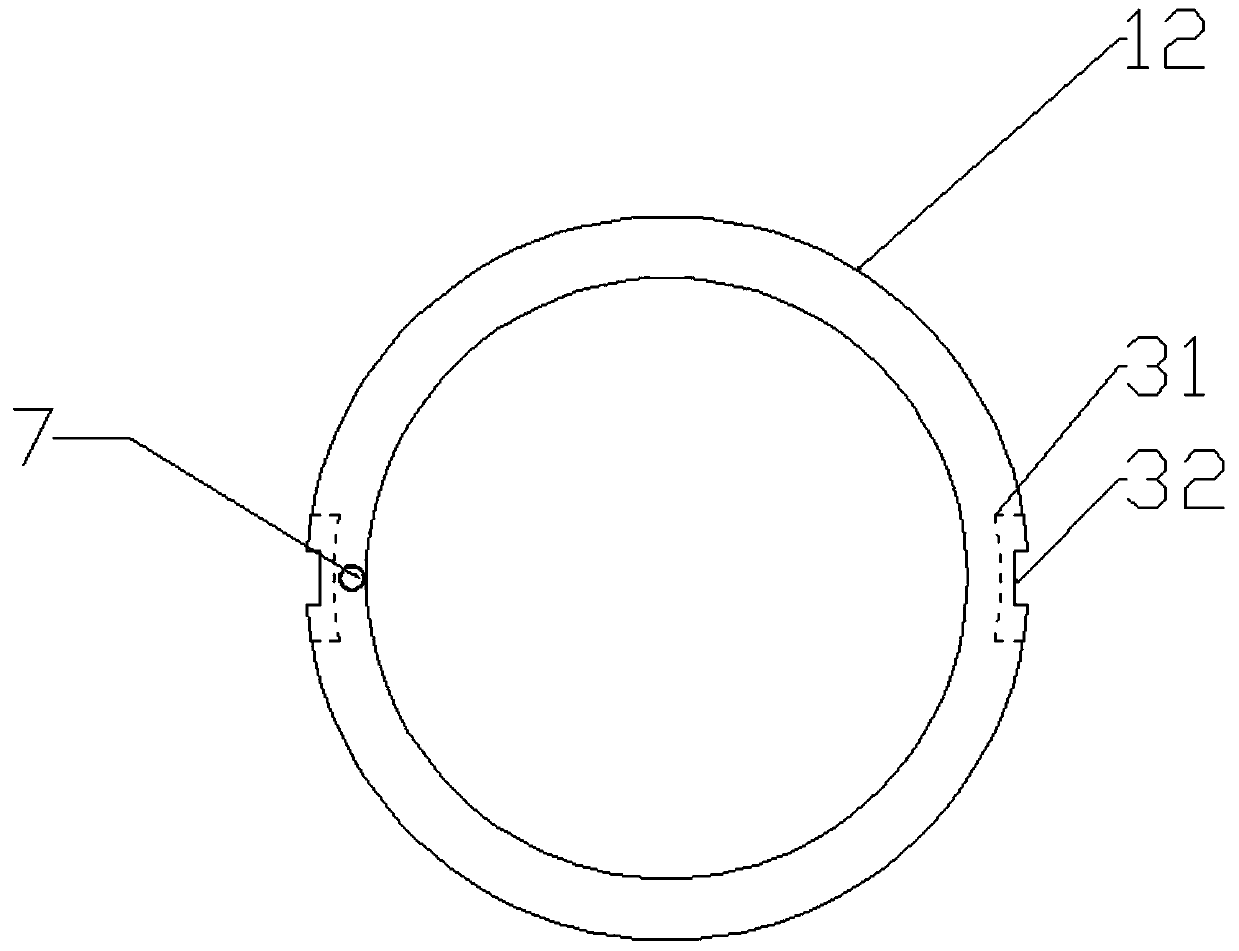

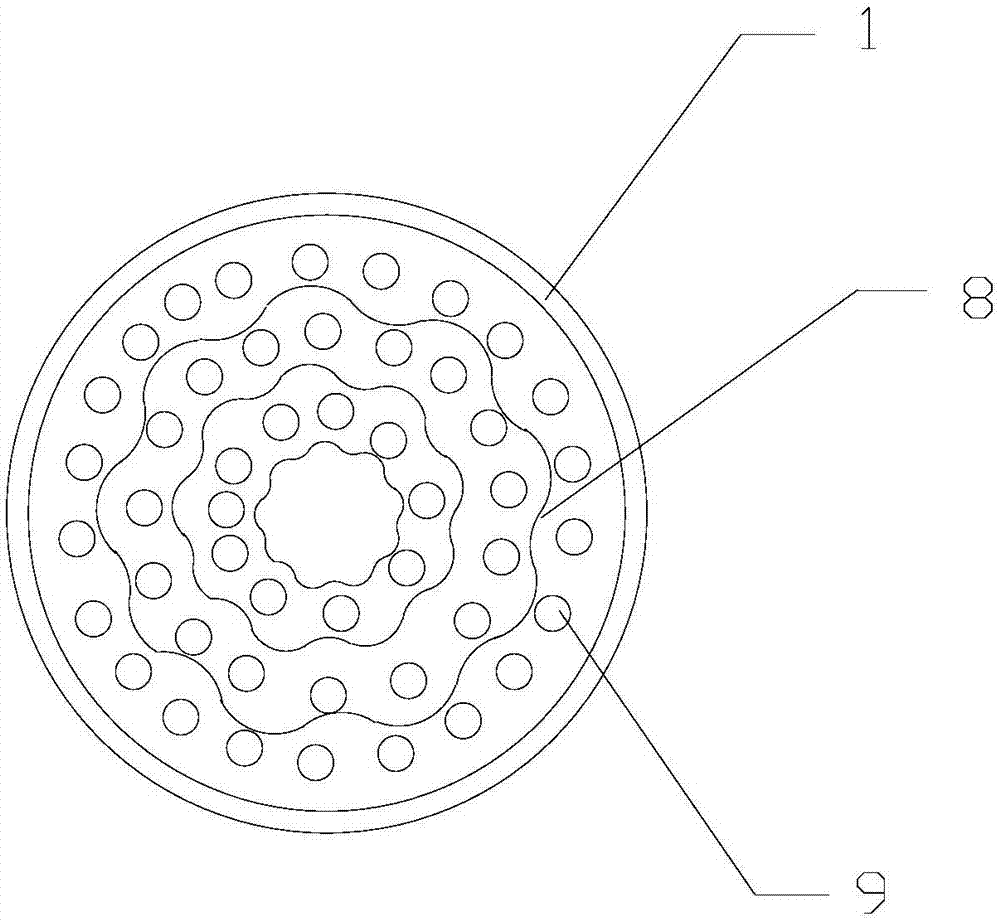

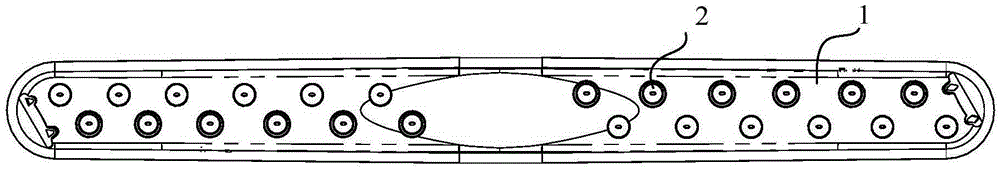

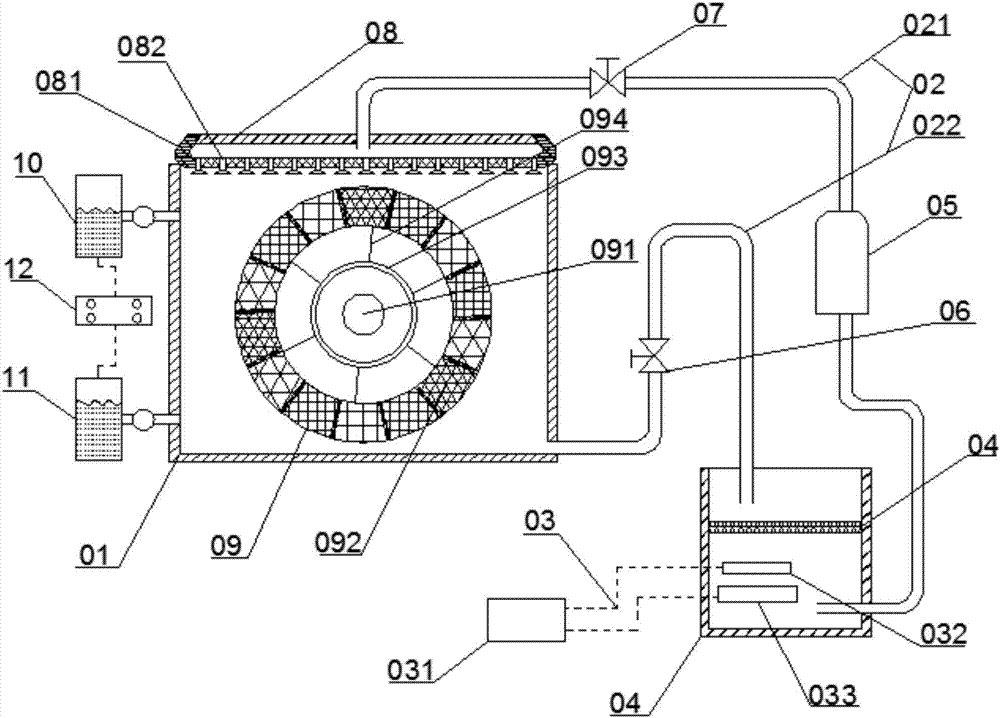

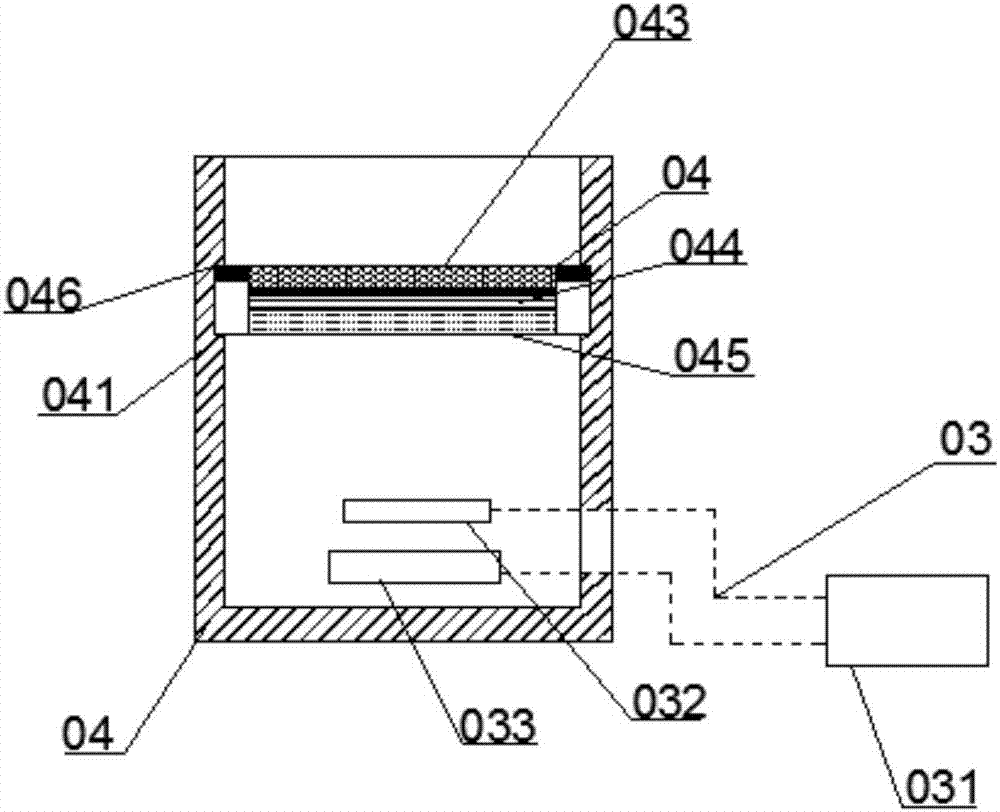

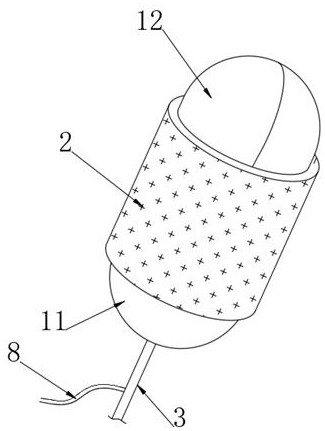

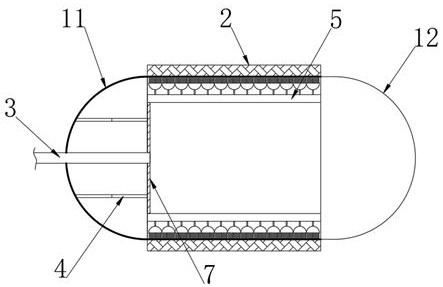

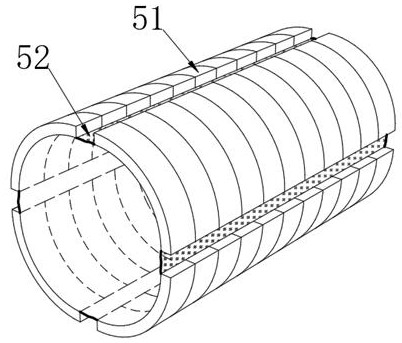

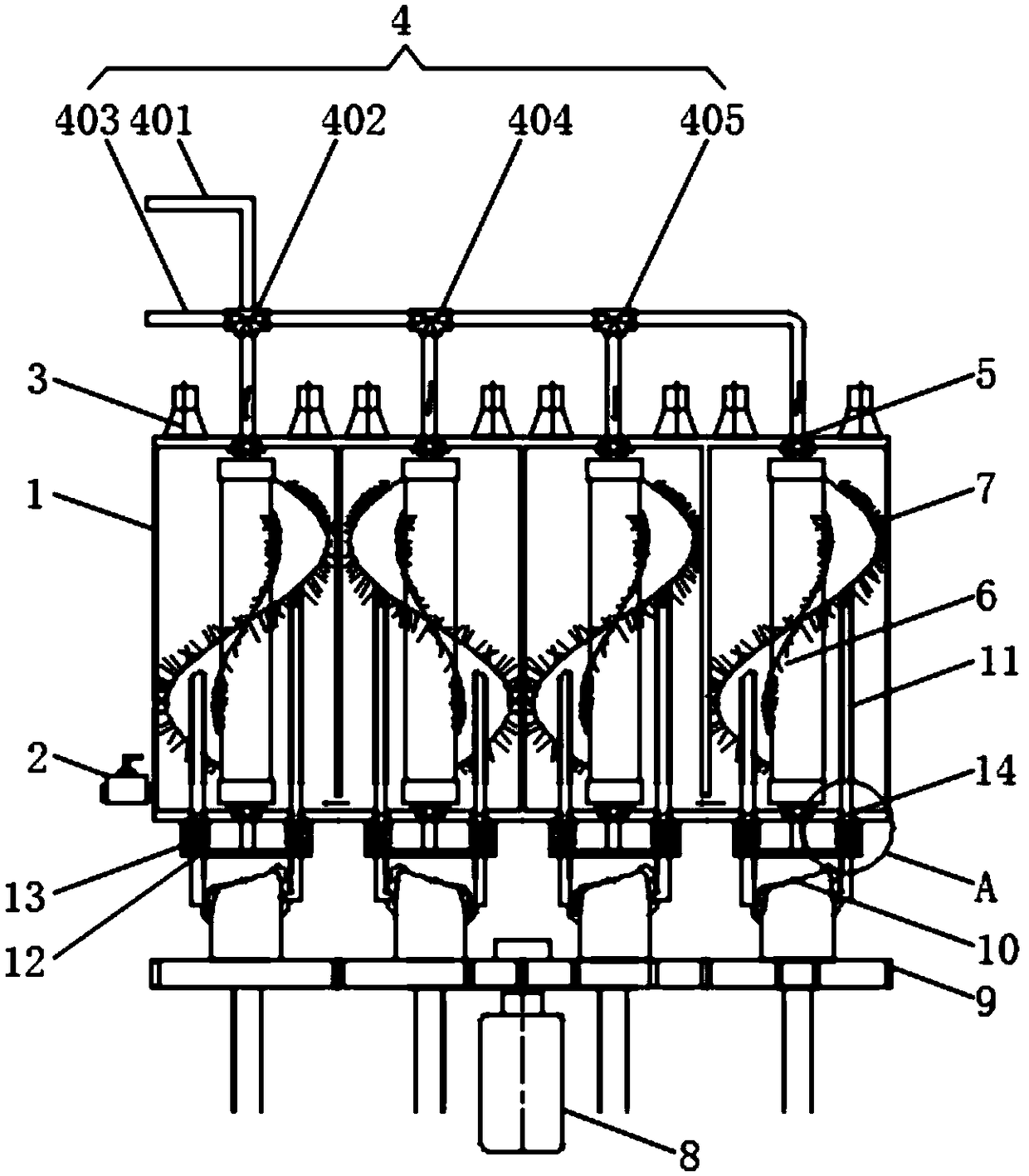

Membrane bioreactor device for retarding membrane pollution and sewage treatment method

ActiveCN104556364AReduce pollutionReduce pollution rateSustainable biological treatmentBiological water/sewage treatmentActivated sludgeWater quality

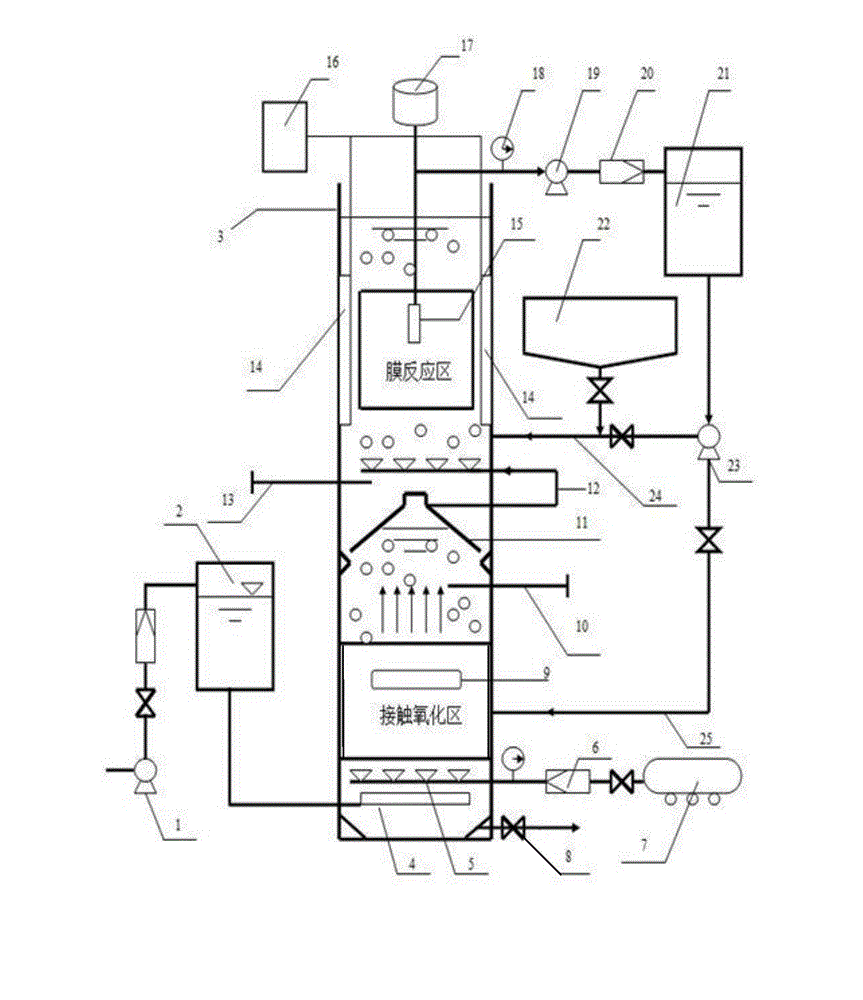

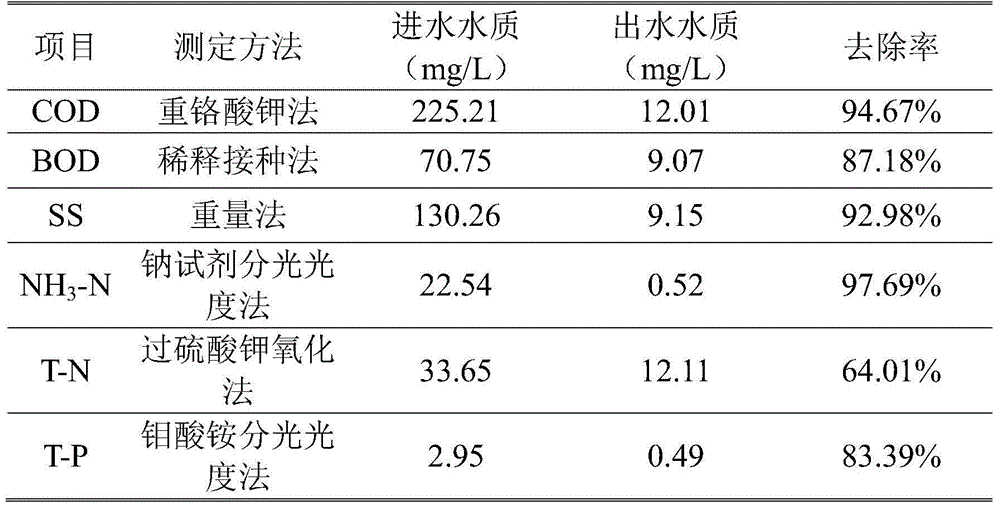

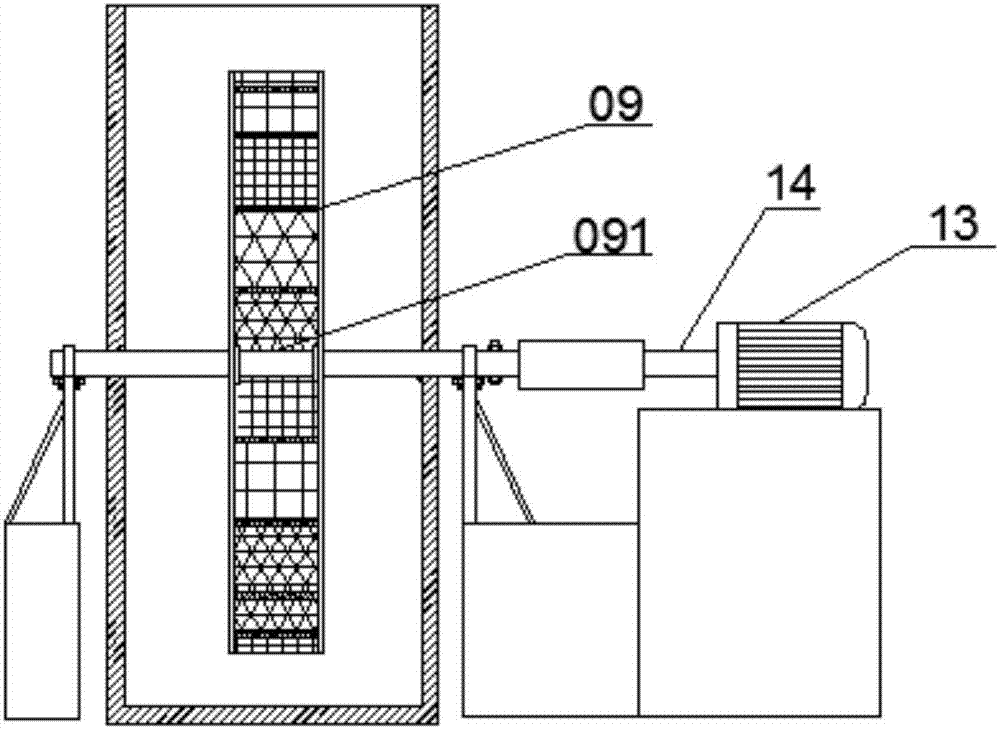

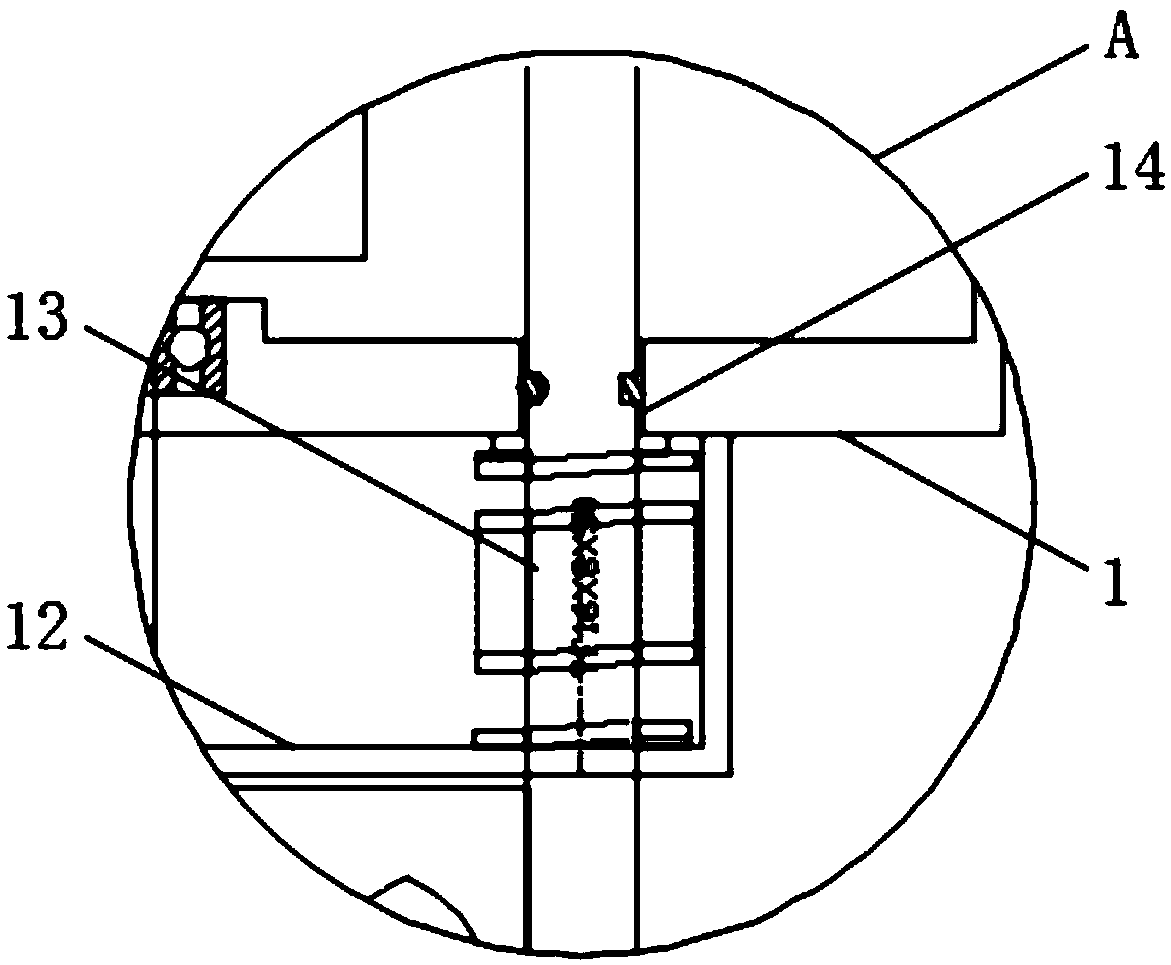

The invention provides a membrane bioreactor device for retarding membrane pollution and a sewage treatment method. The membrane bioreactor device is characterized in that a three-phase separator is arranged in a membrane bioreactor, and a sewage treatment device with a membrane reaction zone at the upper part and a contact oxidation zone at the lower part is formed; sewage enters the contact oxidation zone from the bottom of the reactor and then enters the membrane reaction zone from a slit of the three-phase separator; under the combined action of the absorption of activated sludge and the interception of membranes, the treatment of the sewage is realized; with the adoption of a rotating membrane filtering component, the rotating shear force is increased to retard the membrane pollution, and meanwhile, the fact that all the membranes have uniform cleaning strength is guaranteed, and cleaning dead corners are reduced; the three-phase separator is connected with a gas guide tube, so that residual gas in the contact oxidation zone is guided into the membrane reaction zone at the upper part to be used as a gas washing source of a membrane component, therefore the energy consumption is reduced; online ultrasonic cleaning and chemical cleaning equipment is arranged to reduce the assembly and disassembly procedures in the membrane cleaning process. The sewage treatment device and method have the advantages of high treatment efficiency, small membrane pollution, stable effluent water quality and good convenience in operation and management.

Owner:LIAONING BEIFANG ENVIRONMENTAL PROTECTION

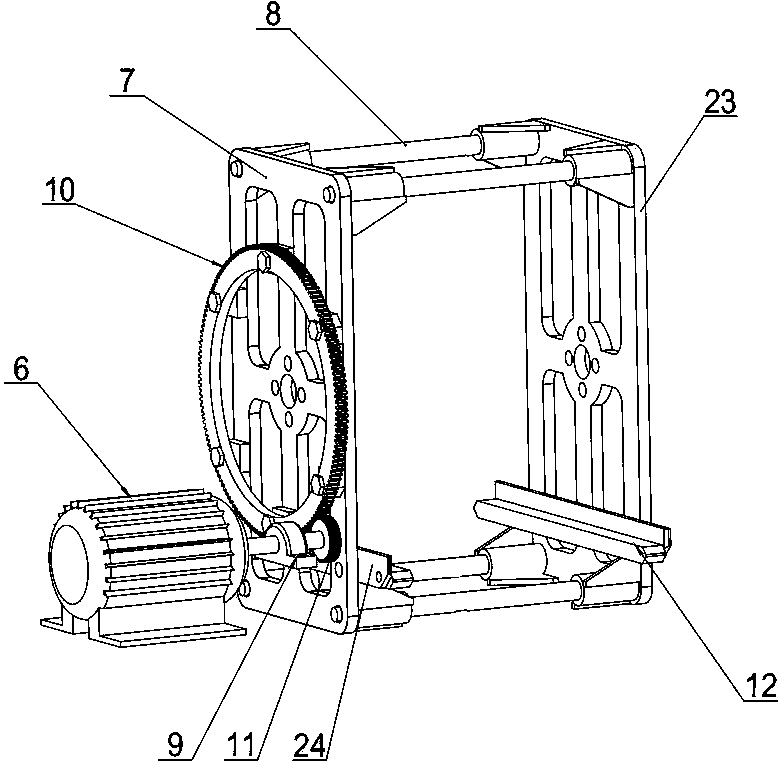

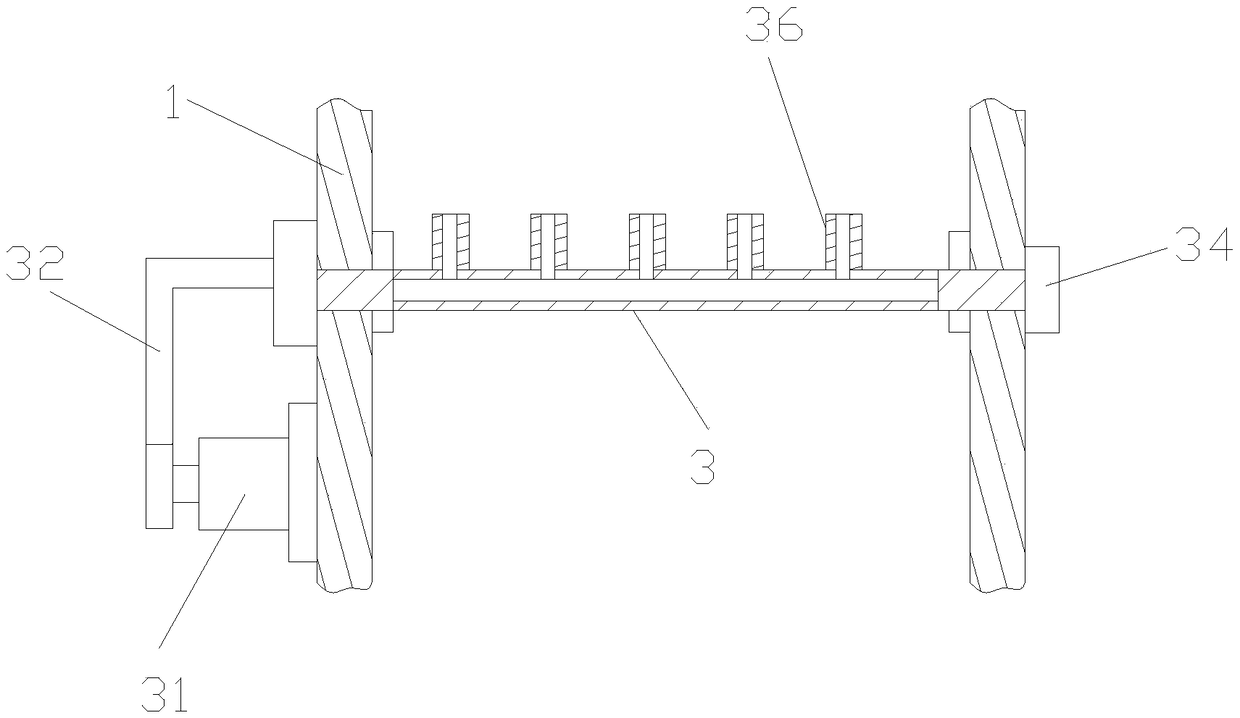

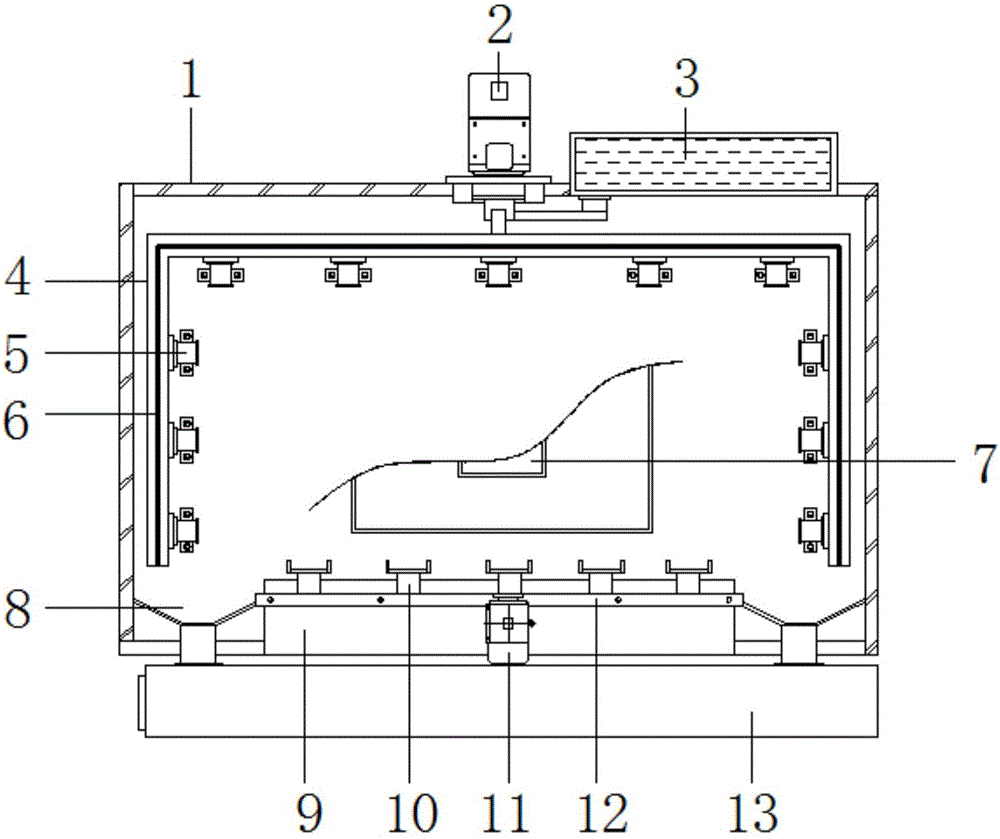

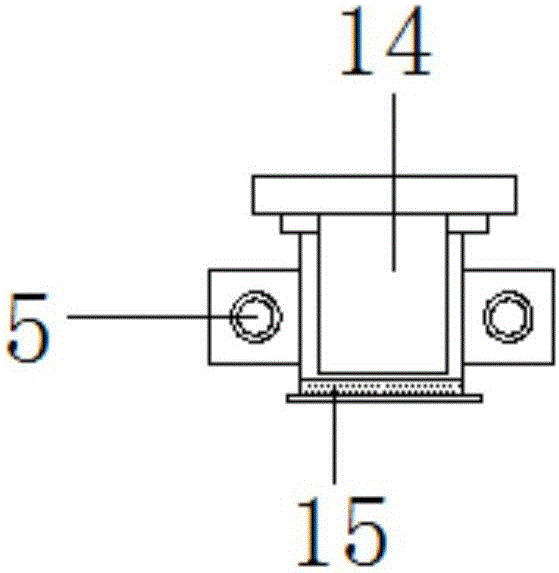

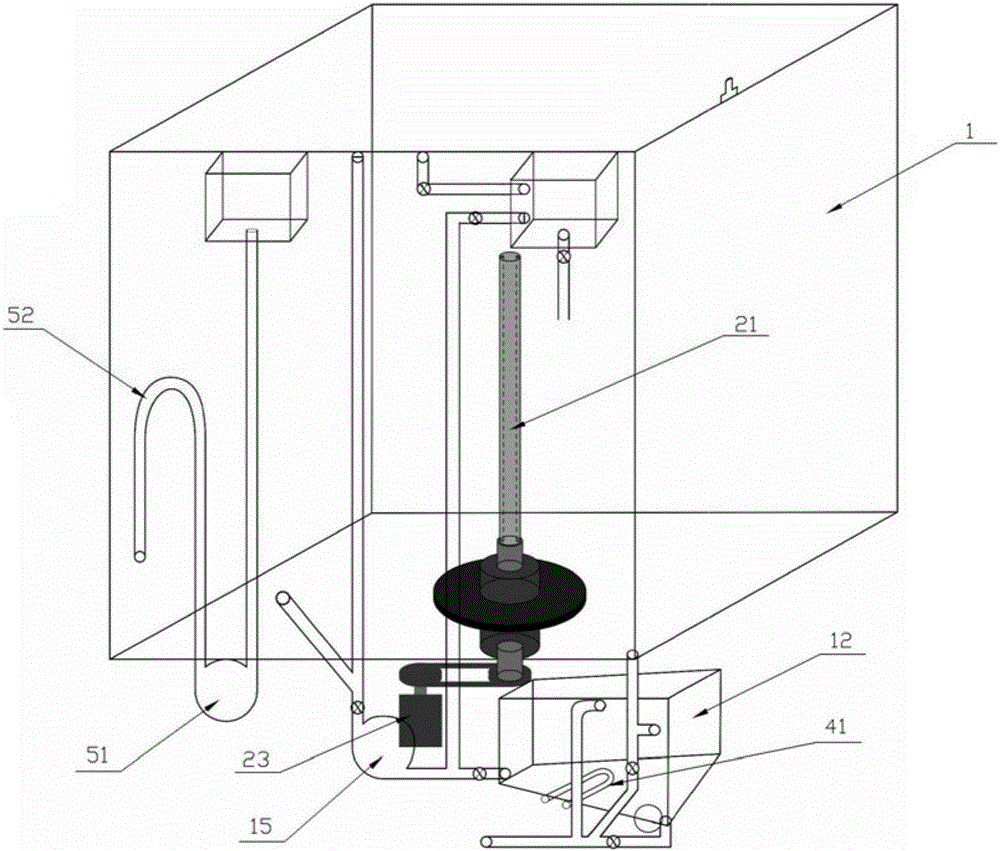

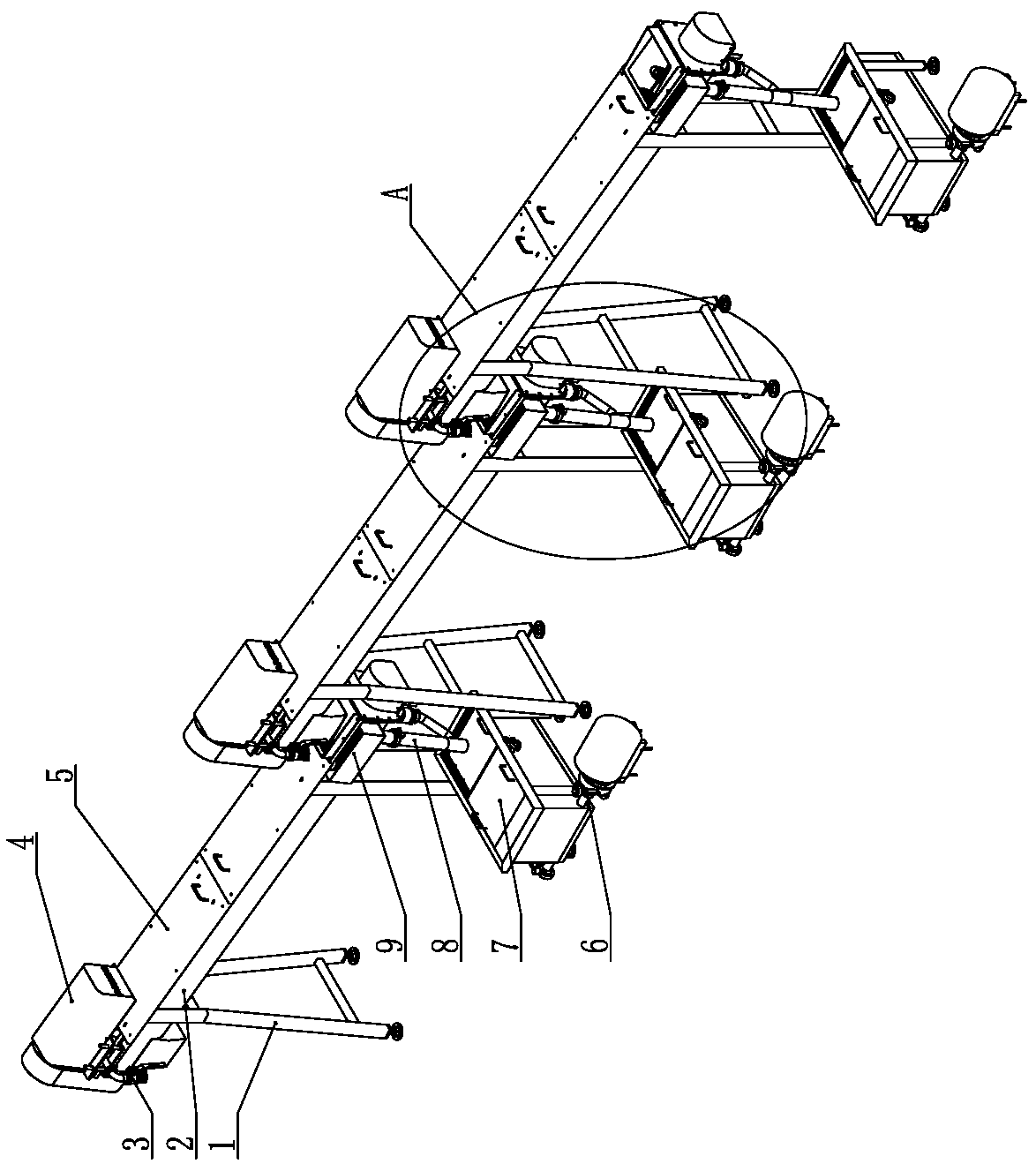

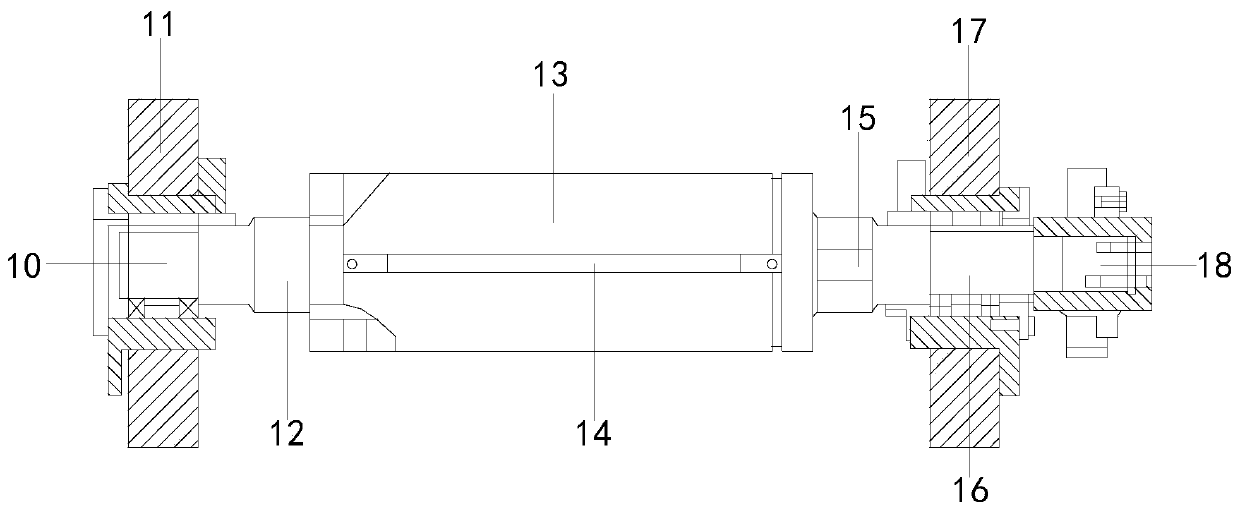

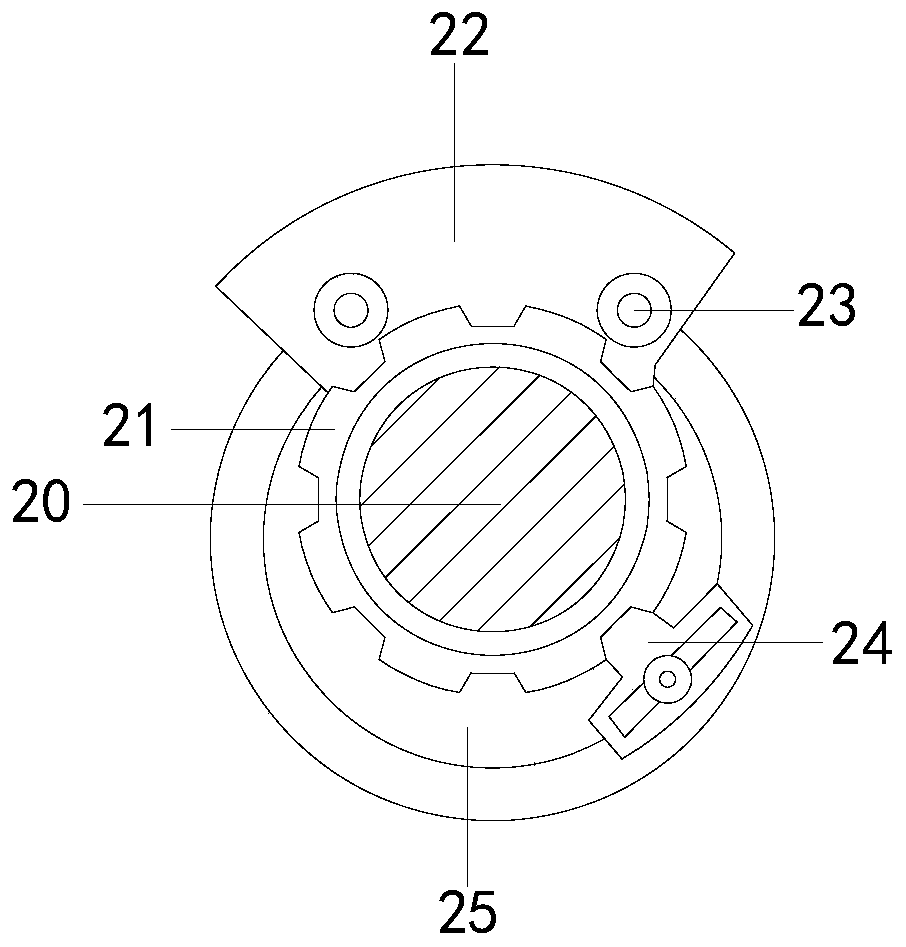

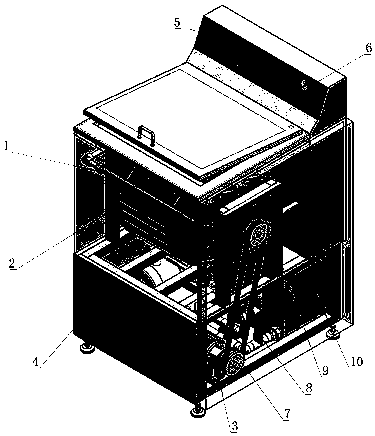

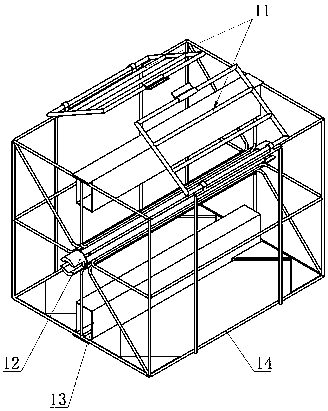

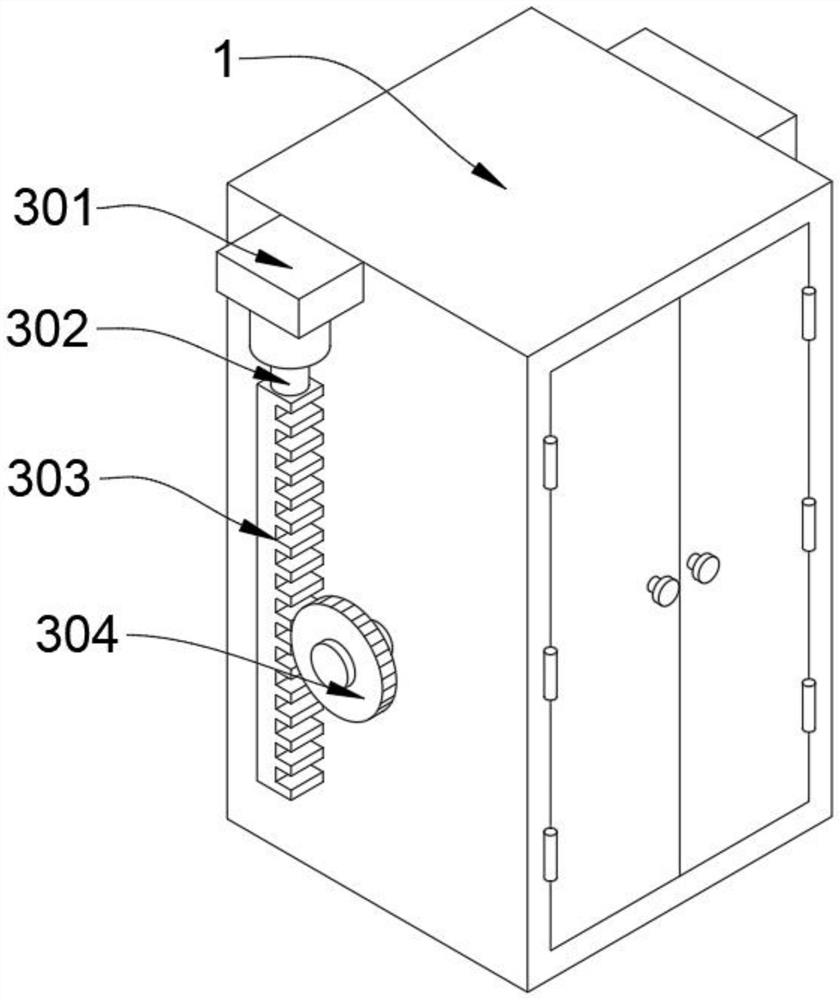

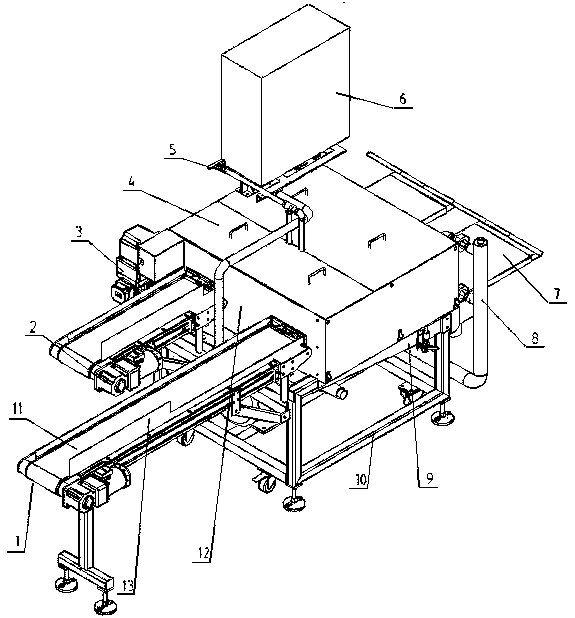

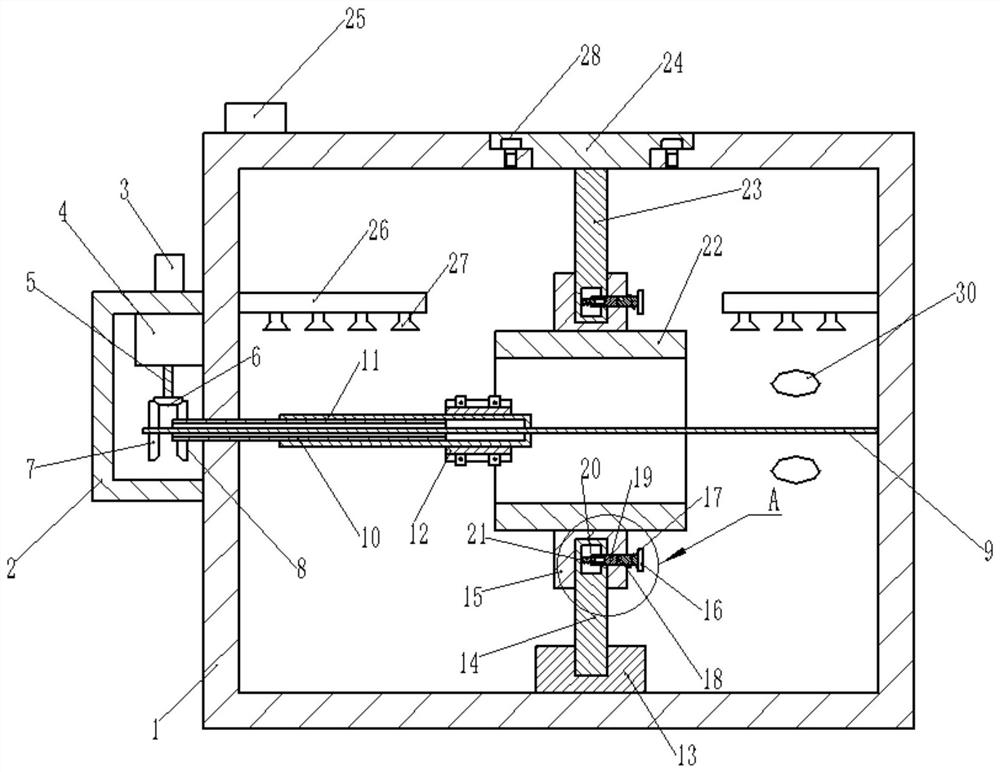

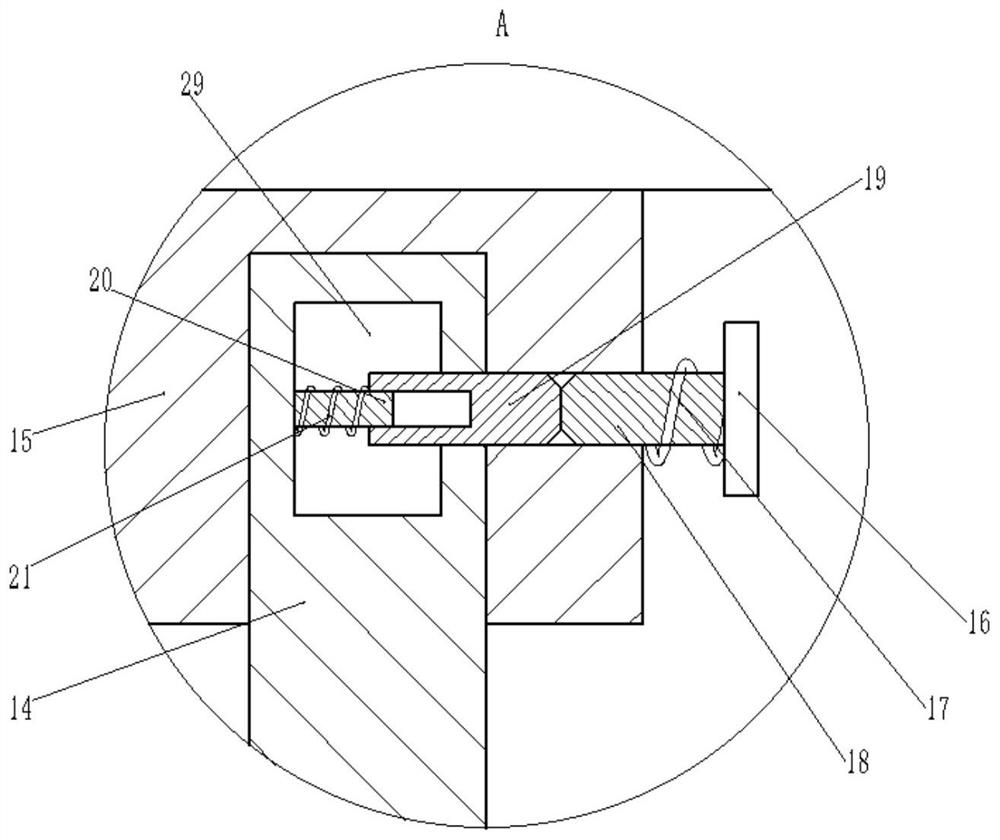

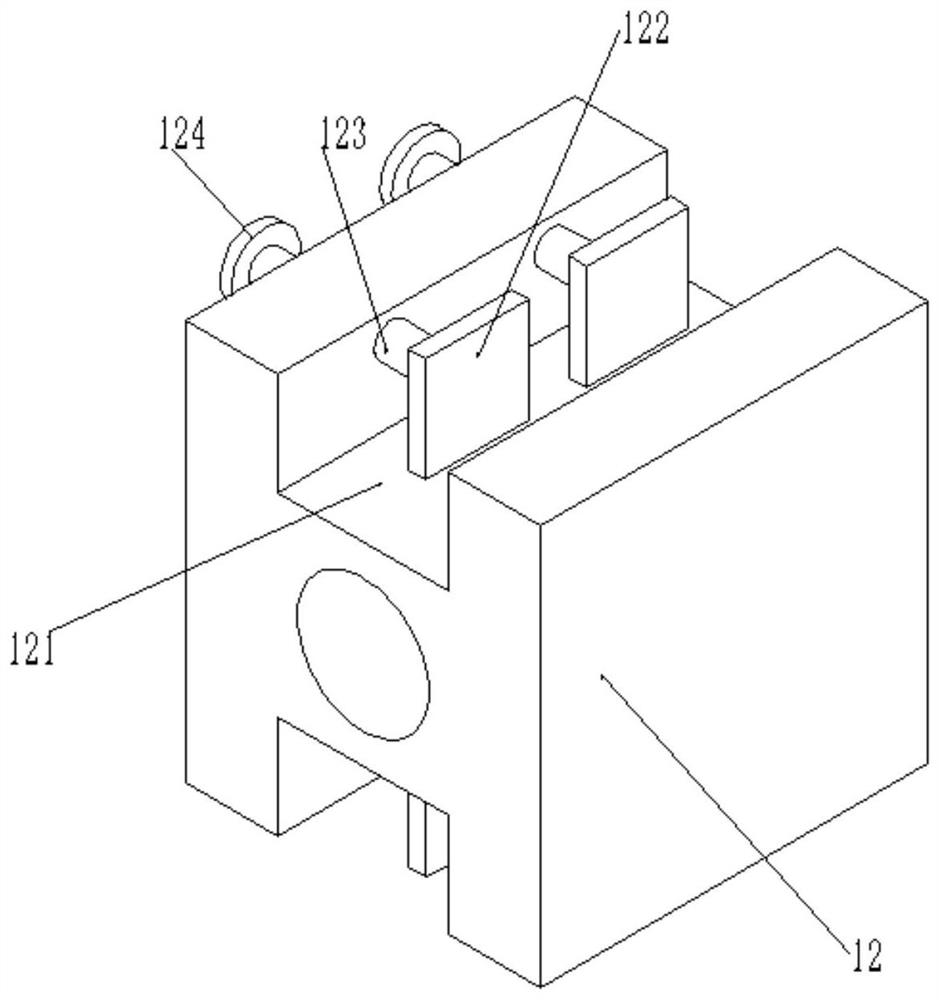

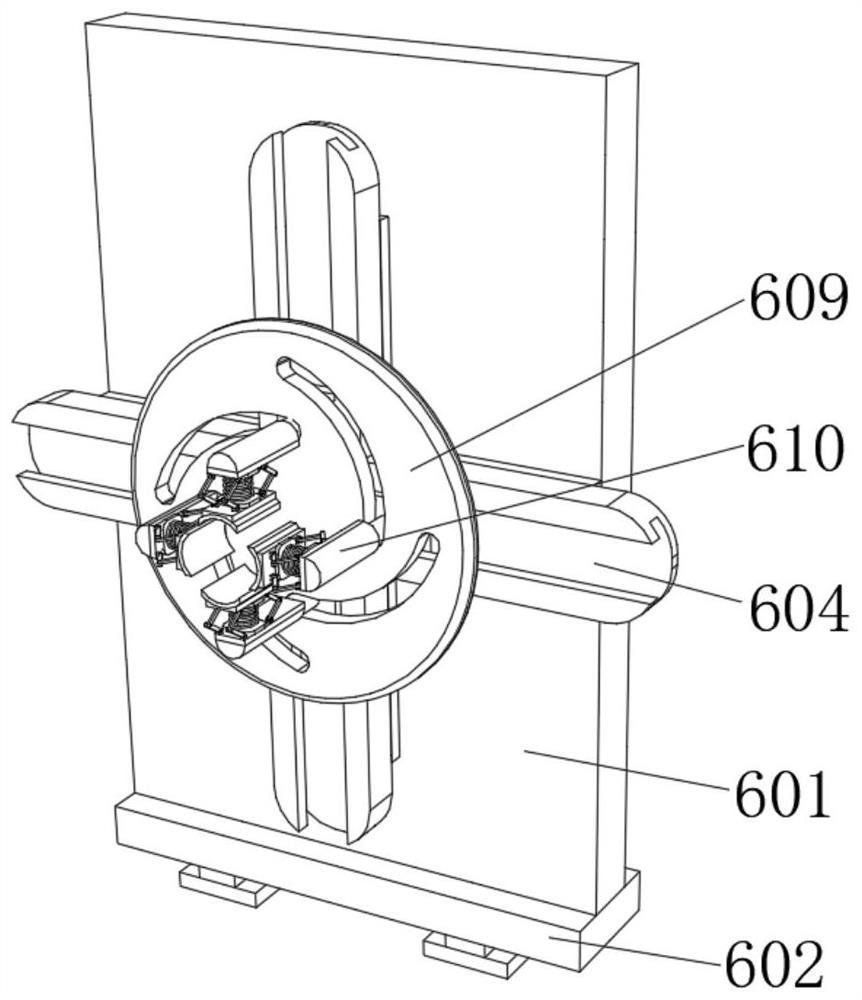

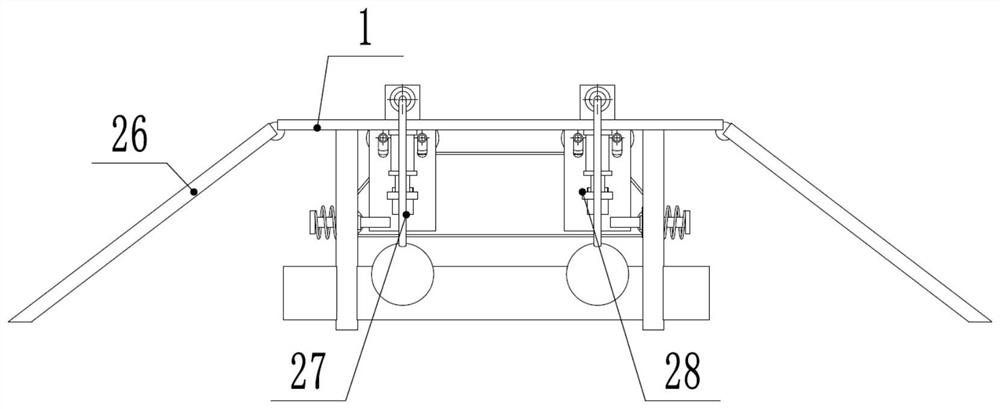

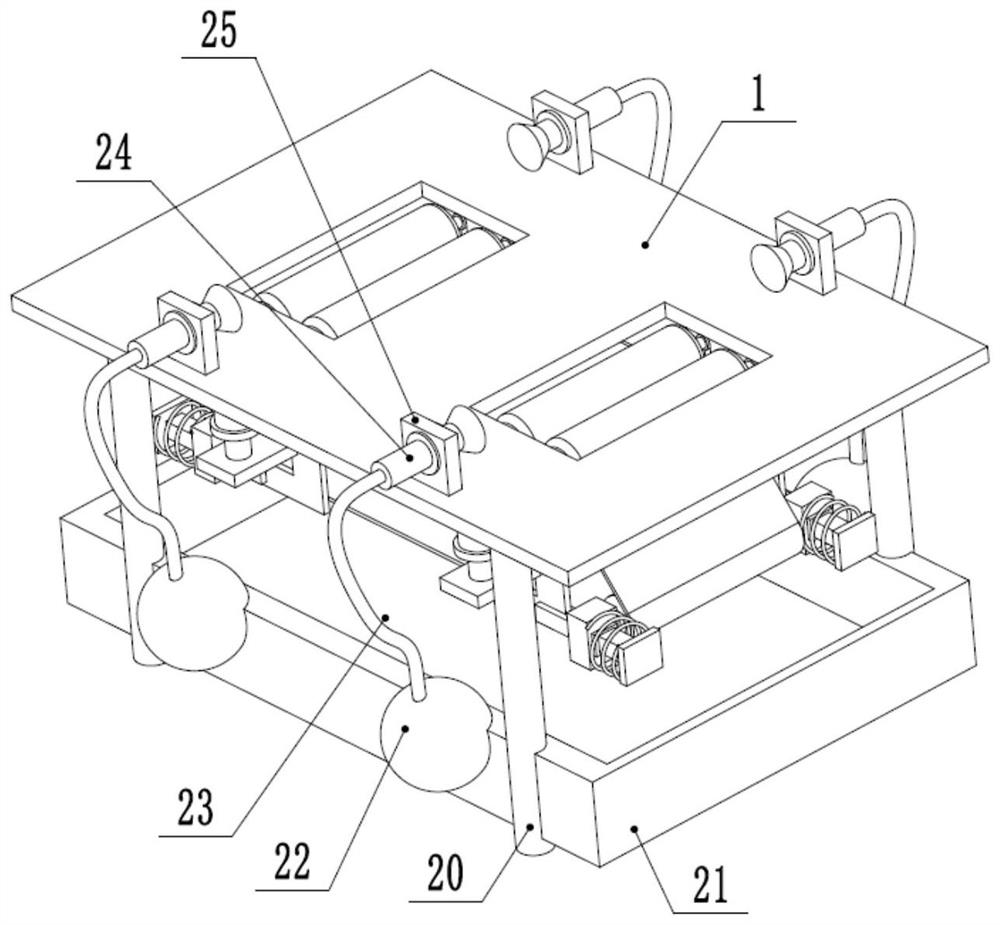

Automatic turnover tool for cleaning of box type shell workpiece

ActiveCN104014573AIncrease coverageReduce cleaning dead angleCleaning using liquidsPistonProduction line

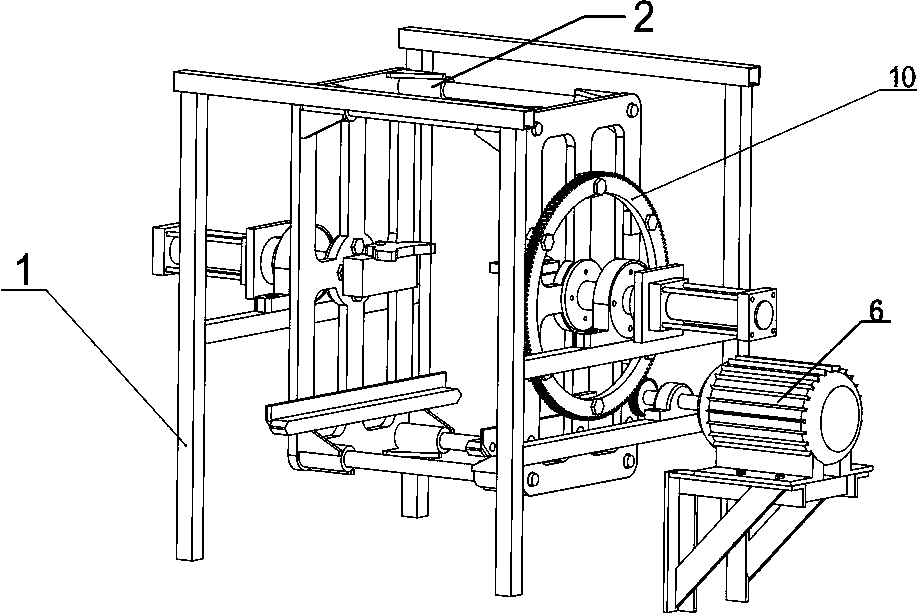

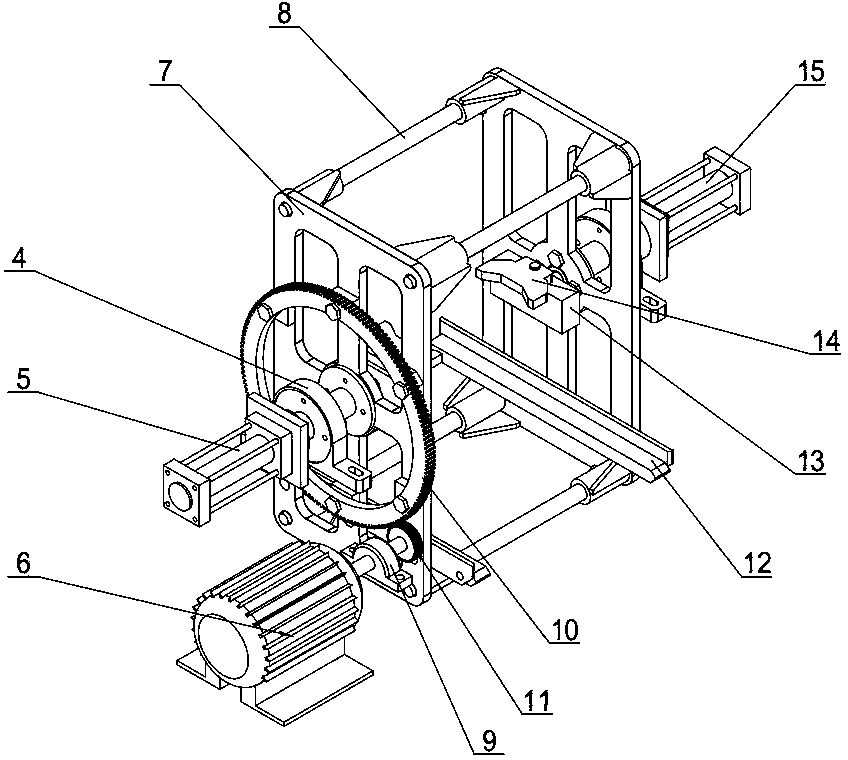

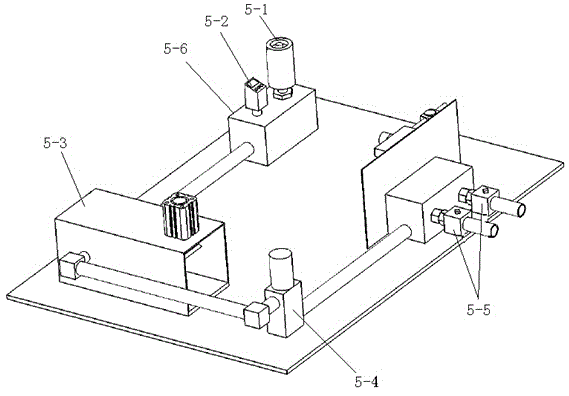

The invention relates to an automatic turnover tool for cleaning of a box type shell workpiece. The automatic turnover tool comprises a rack, a turnover frame, a turnover drive mechanism and a clamping mechanism. The turnover frame is located in the rack. Air cylinders are installed outside the two laterally-symmetrical sides of the turnover frame respectively, a main gear ring is installed outside one side of the turnover frame, a linkage gear meshed with the main gear ring is arranged on an output shaft of a motor, and the motor, the main gear ring and the linkage gear form the turnover drive mechanism. The clamping mechanism comprises the two air cylinders and two clamping plates, the two air cylinders are installed outside the two sides of the turnover frame in a laterally-symmetrical mode, and the clamping plates, connected with piston rods, on the two air cylinders are symmetrically located in the turnover frame. Fixing installation supports on the two air cylinders are fixed to the two sides of the rack respectively. The turnover frame can achieve 180-degree reciprocating rotation and can be used for cleaning of a production line, the coverage rate of the cleaned surface of the workpiece is higher and coverage is more uniform, generation of more cleaning dead angles is reduced, and cleaning quality of the workpiece is improved.

Owner:ANHUI HELI CO LTD

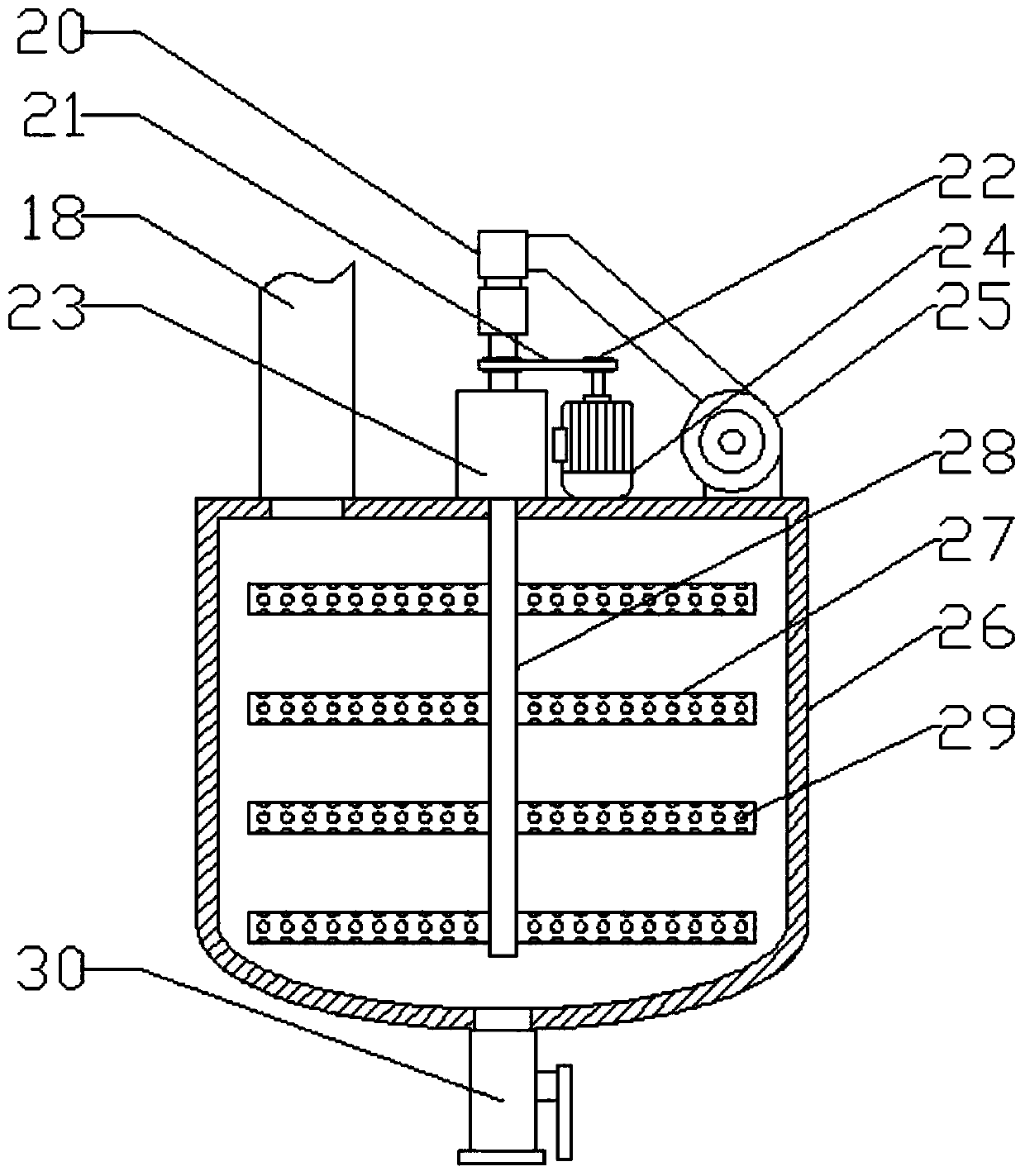

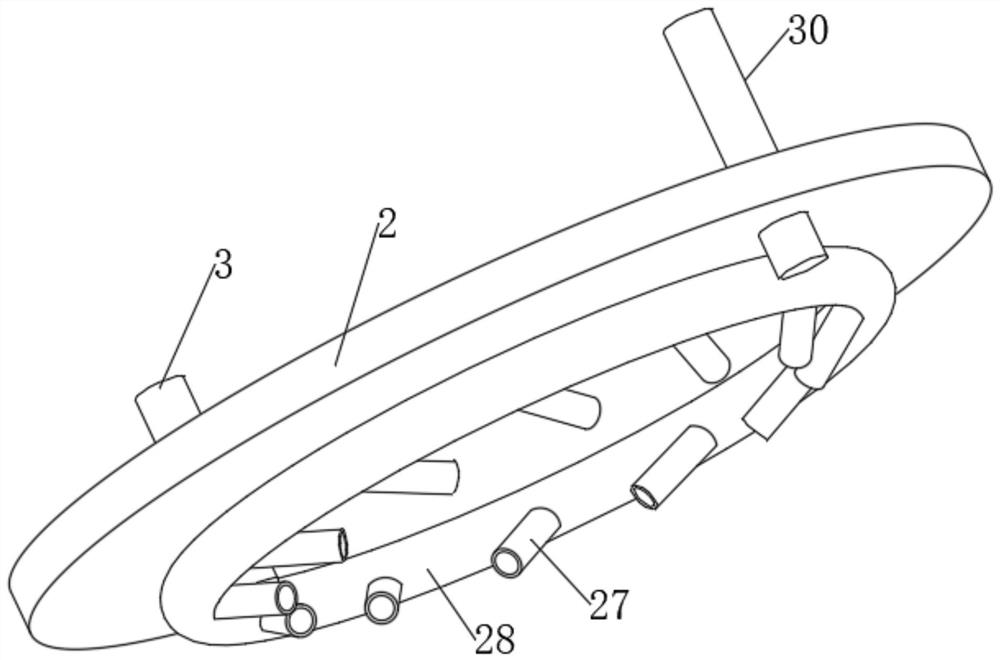

Cleaning device for plastic particles

InactiveCN110976375AImprove uniformityEasy to cleanCleaning using toolsCleaning using liquidsBristleElectric machinery

The invention discloses a cleaning device for plastic particles. The cleaning device comprises a first barrel, wherein the upper end of the first barrel is provided with a material feeding pipe and afirst motor; an output shaft of the first motor is provided with a first rotary shaft which vertically extends into the first barrel; the first rotary shaft is provided with a plurality of first stirring rods; the surface of each first stirring rod is provided with bristles; the inner wall of the first barrel is provided with an annular seat which is attached to the inner wall; an annular cavity is arranged in the annular seat; the circumference of the inner wall of the annular seat is evenly provided with a plurality of water outlets which communicate with the cavity; the upper end of the annular seat is provided with a water feeding pipe which communicates with the cavity; the first barrel is also provided with a driving component; the inner lower end of the first barrel is provided witha filtering net; and the bottom of the first barrel is provided with a pollution discharging pipe. By use of the cleaning device, through the annular seat capable of carrying out reciprocating movement, water is evenly sprayed to the plastic particles, meanwhile, the plastic particles are stirred through the stirring rods and are cleaned through the bristles, a cleaning evenness degree of the plastic particles is improved, cleaning dead angles are reduced, and a cleaning effect is improved.

Owner:WUHU INST OF TECH

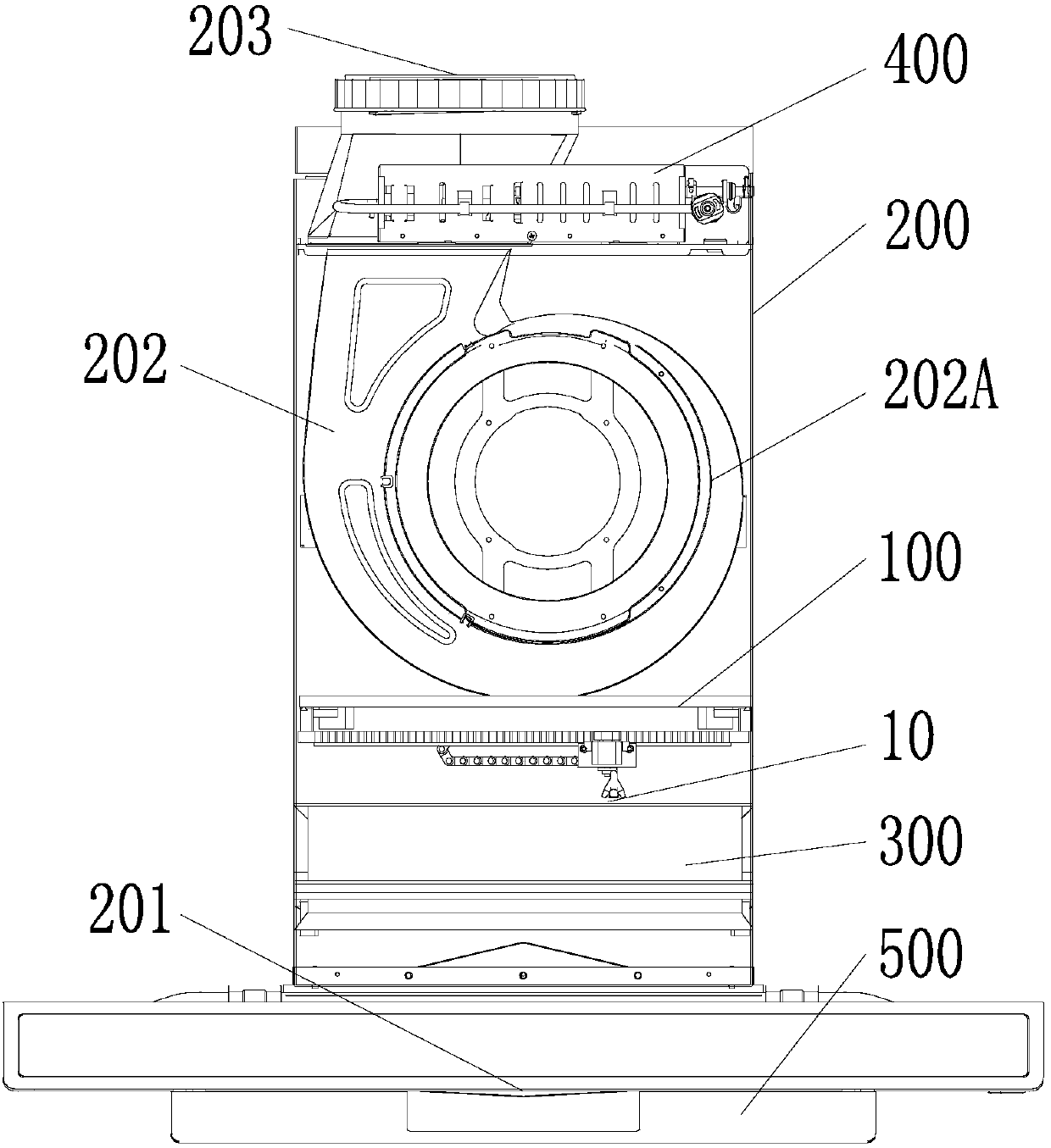

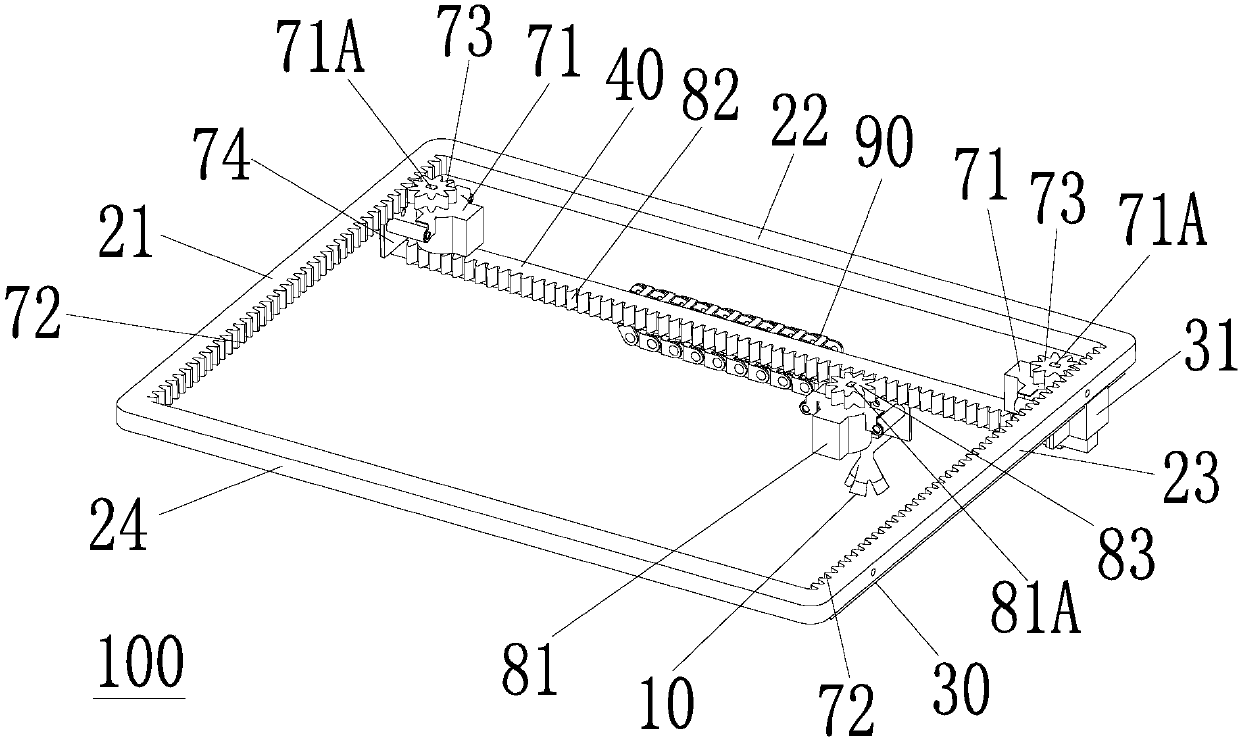

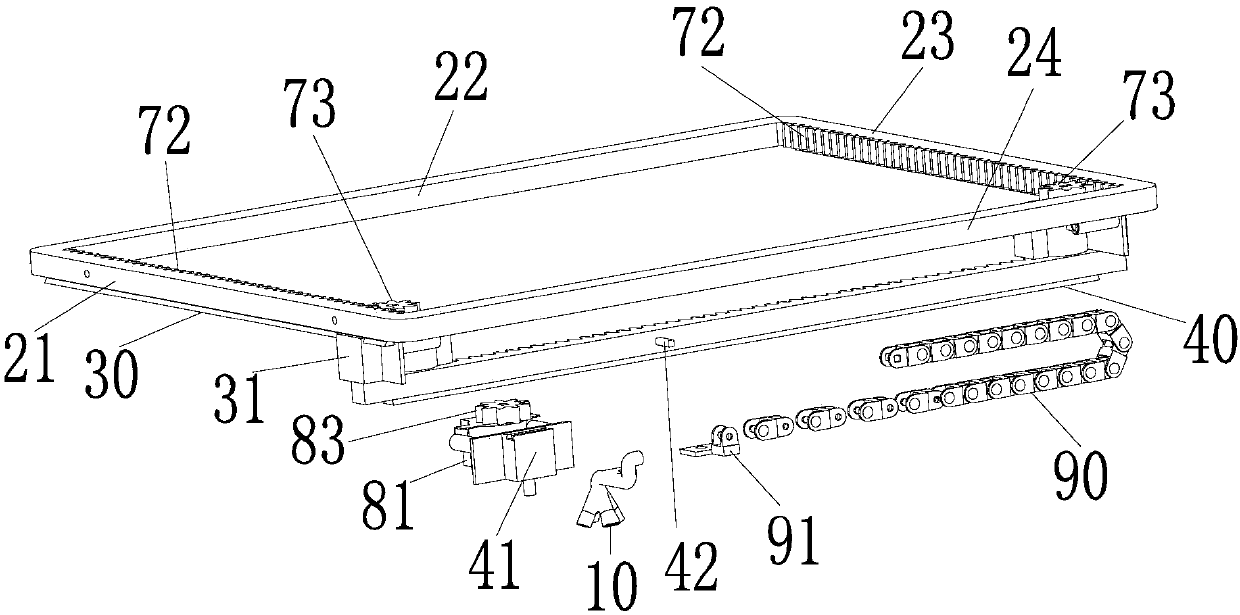

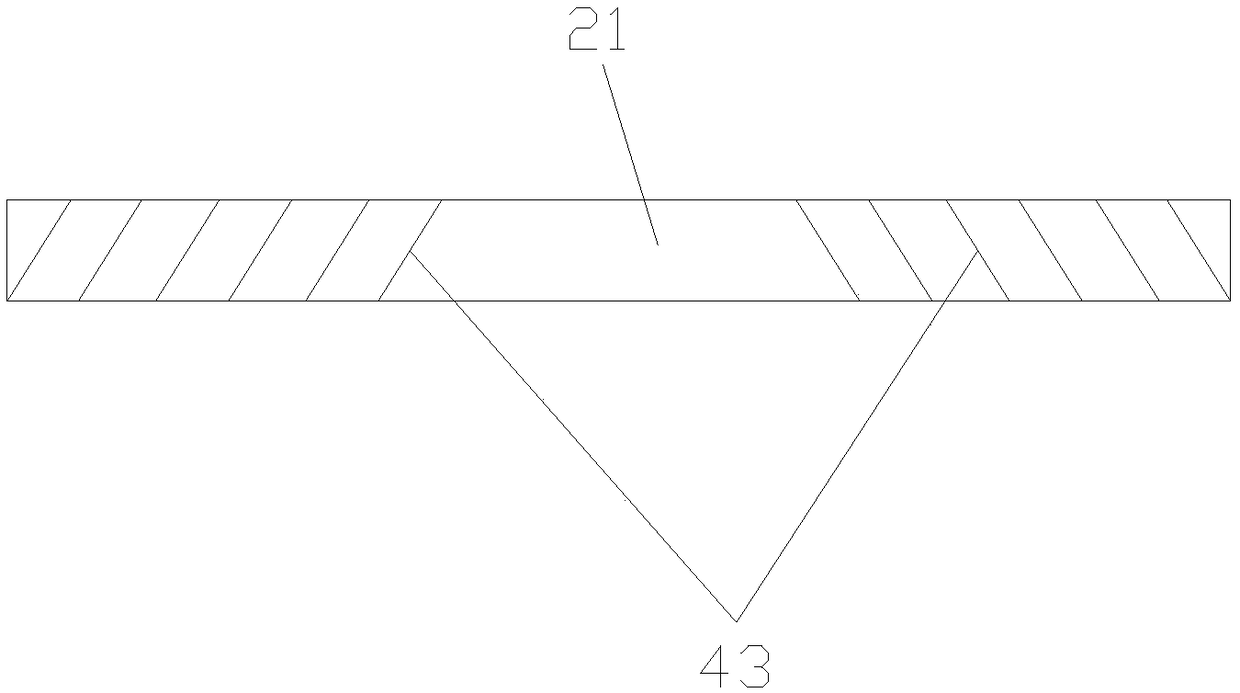

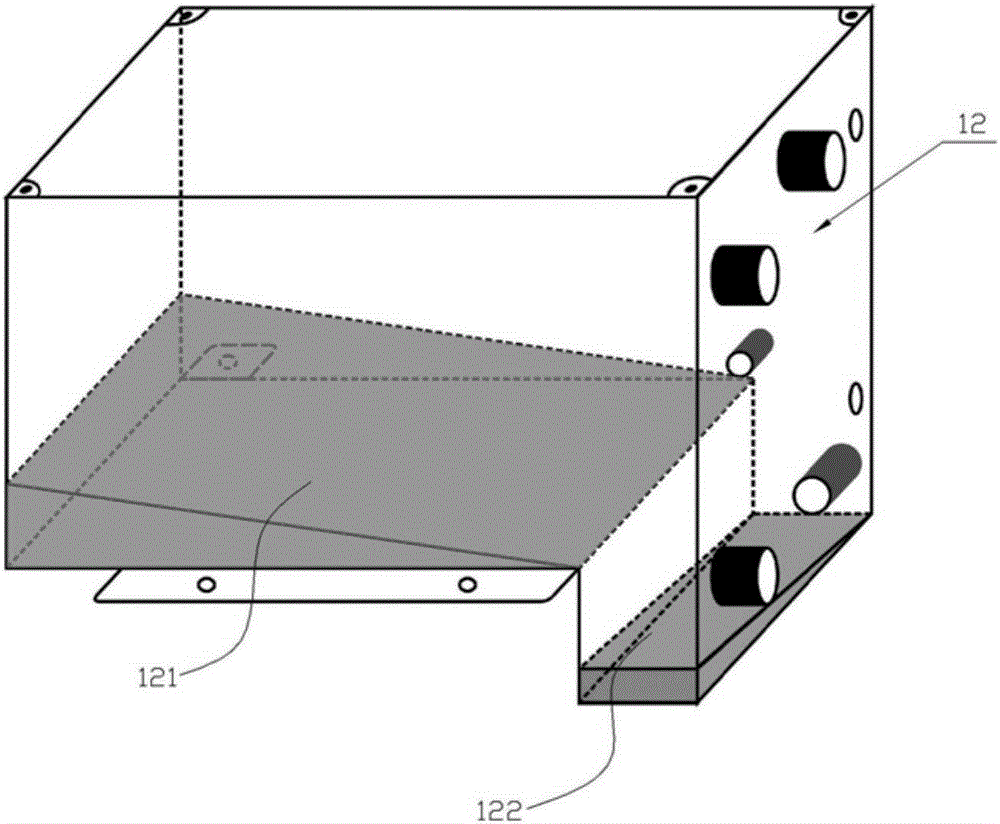

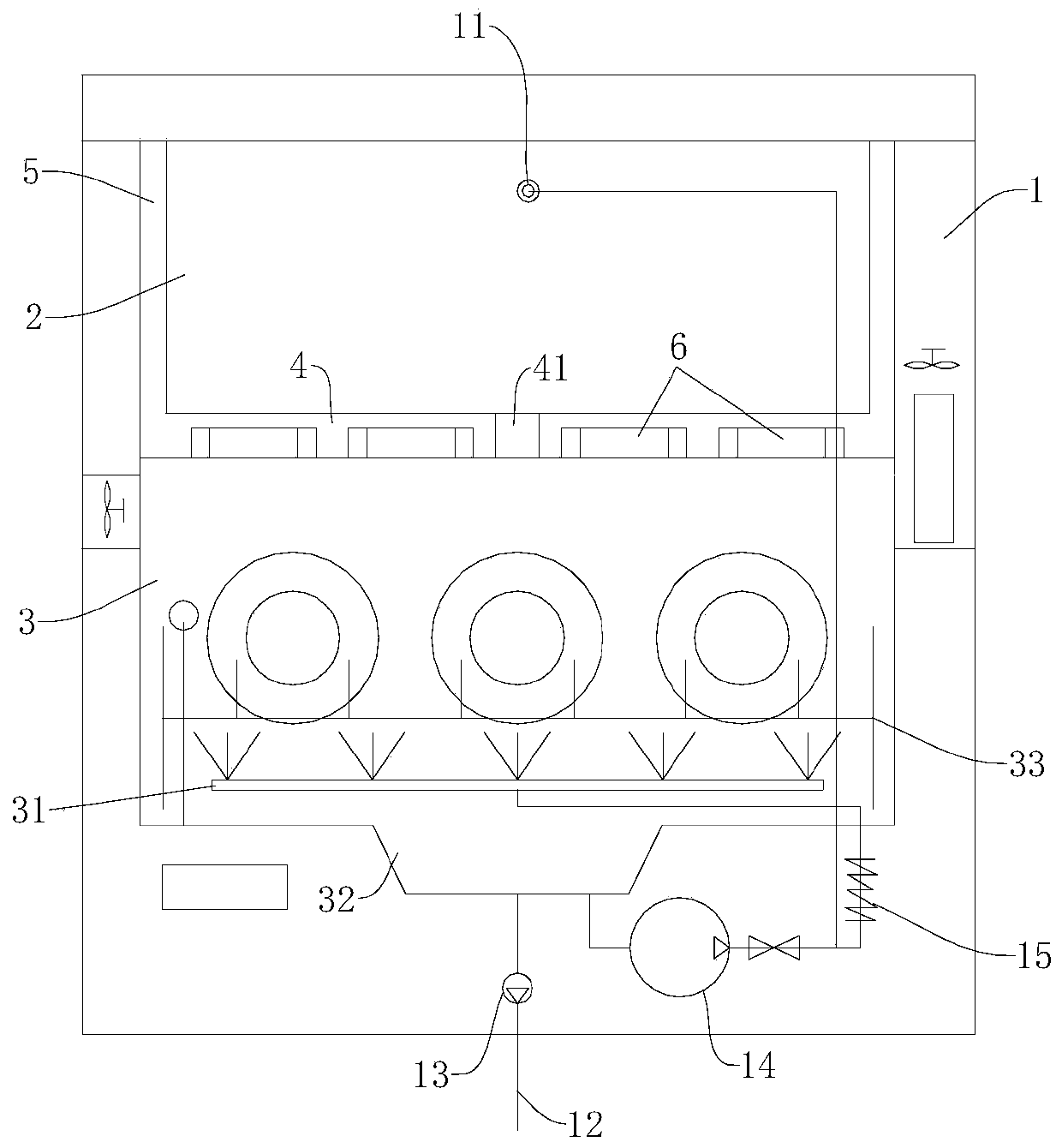

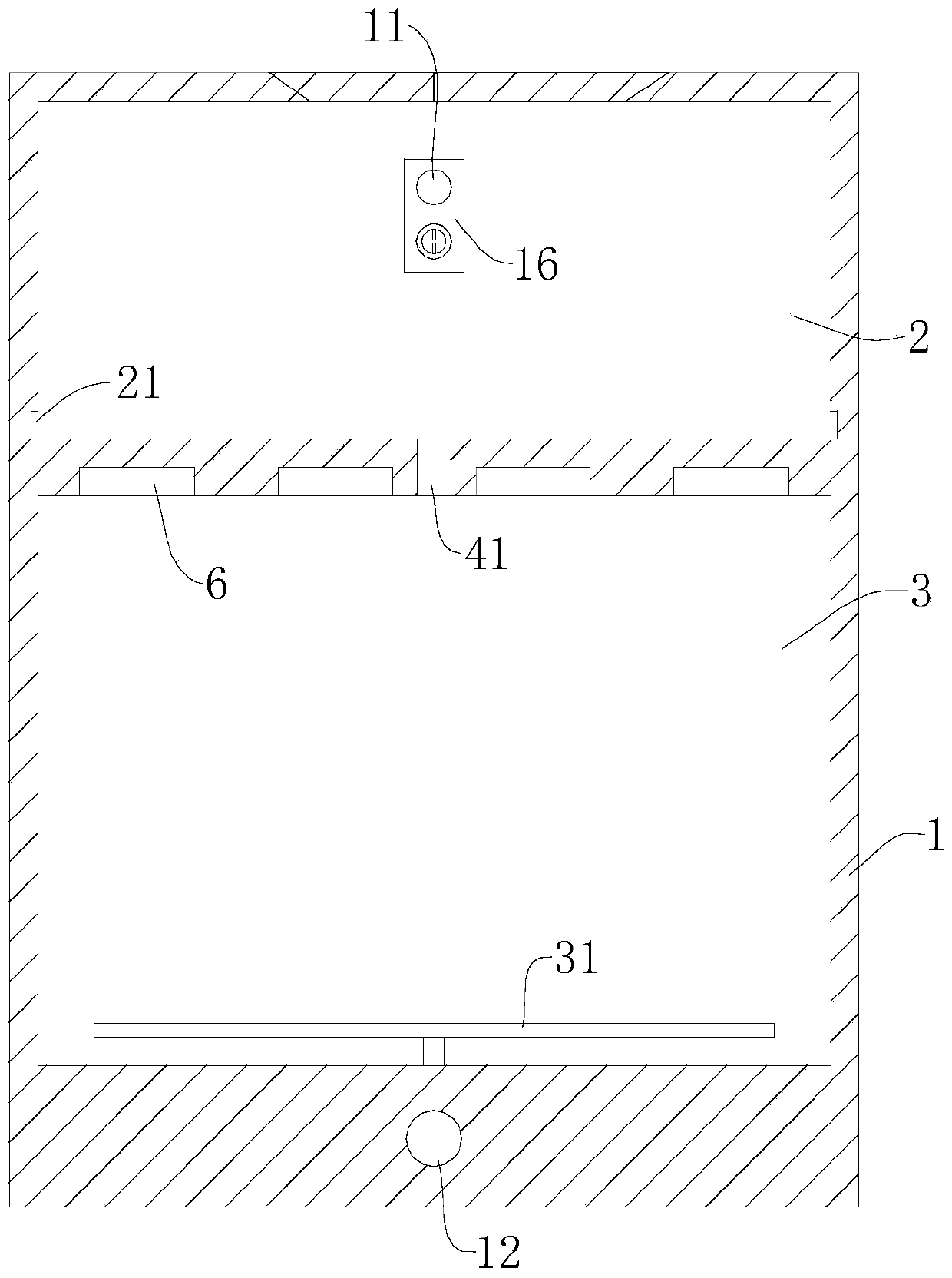

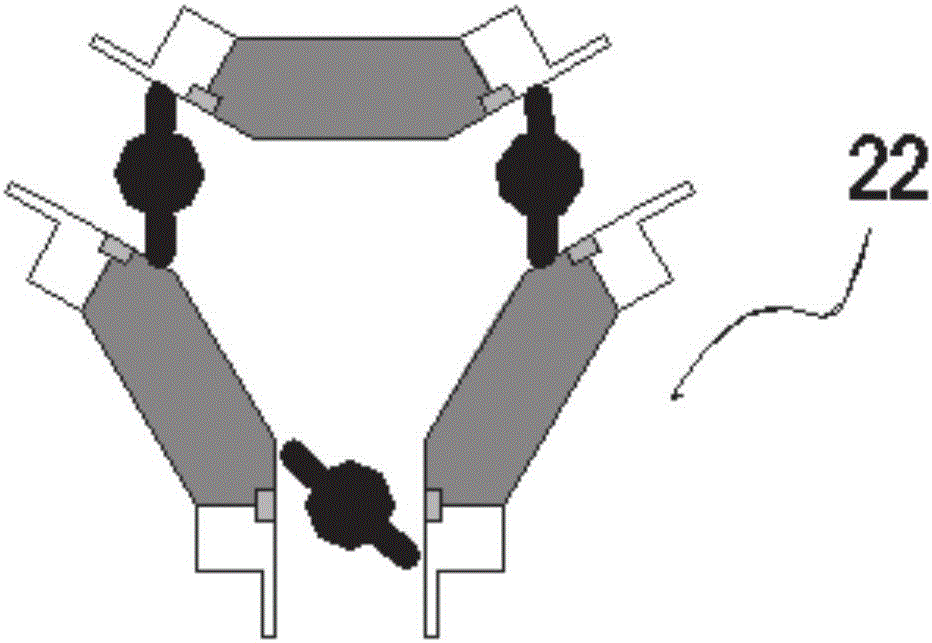

Spray cleaning device and range hood

ActiveCN107747747AImprove cleaning efficiencyIncrease the spray cleaning areaDomestic stoves or rangesLighting and heating apparatusSpray nozzleEngineering

The invention discloses a spray cleaning device and a range hood. The spray cleaning device (100) includes: a mounting frame, which is rectangular in shape and includes, in a successively vertically connected manner, a first frame (21), a second frame (22), a third frame (23) and a fourth frame (24); frame rails (30), which are arranged on the first frame and / or the third frame; a moving rail (40), which is in parallel with the second frame and the fourth frame, wherein two ends of the moving rail are provided with frame rail slide pieces (31) in sliding fit with the frame rails, the moving rail provided with a moving rail slide piece (41); a frame rail driving mechanism, which drives the frame rail slide pieces to slide along the frame rails; a moving rail driving mechanism, which drivesthe moving rail slide piece to slide along the moving rail; and a spray nozzle (10) being connected to the moving rail slide piece. In the structure, the spray nozzle can freely move on a two-dimensional plane within the mounting frame, so that spray cleaning area is effectively increased, cleaning dead angle is reduced, and cleaning efficiency is increased.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

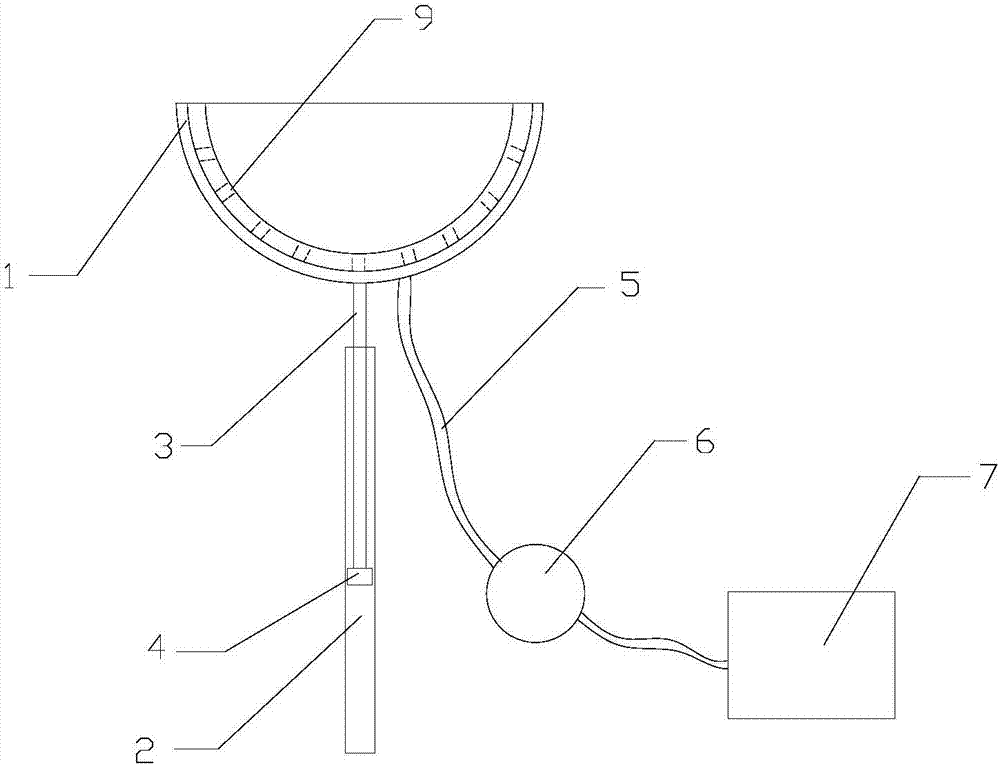

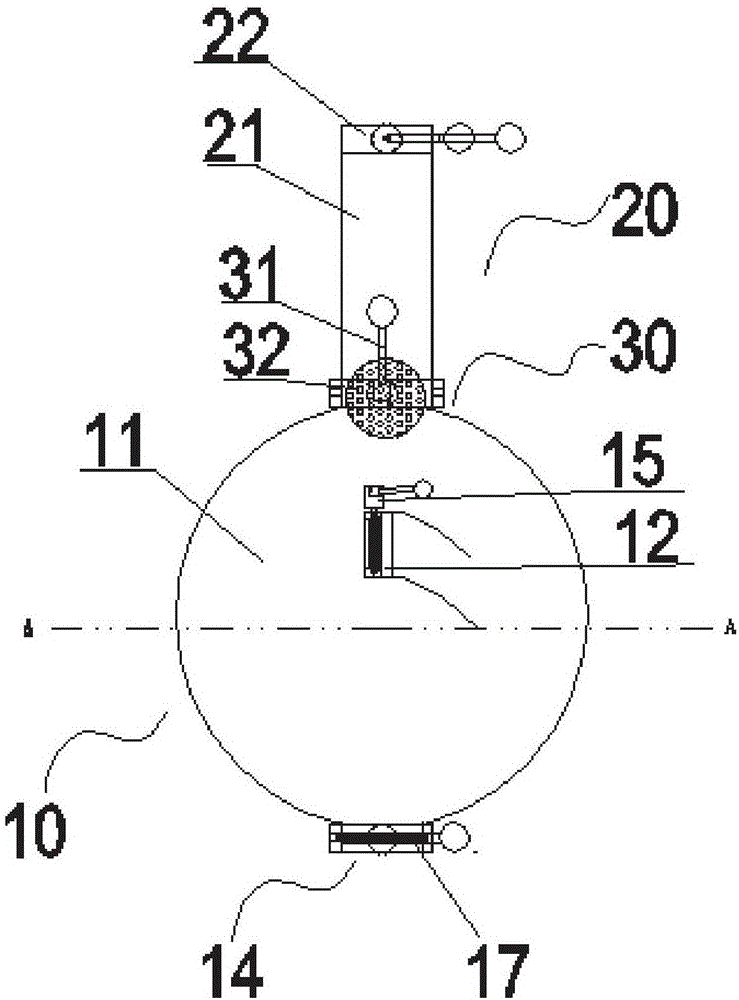

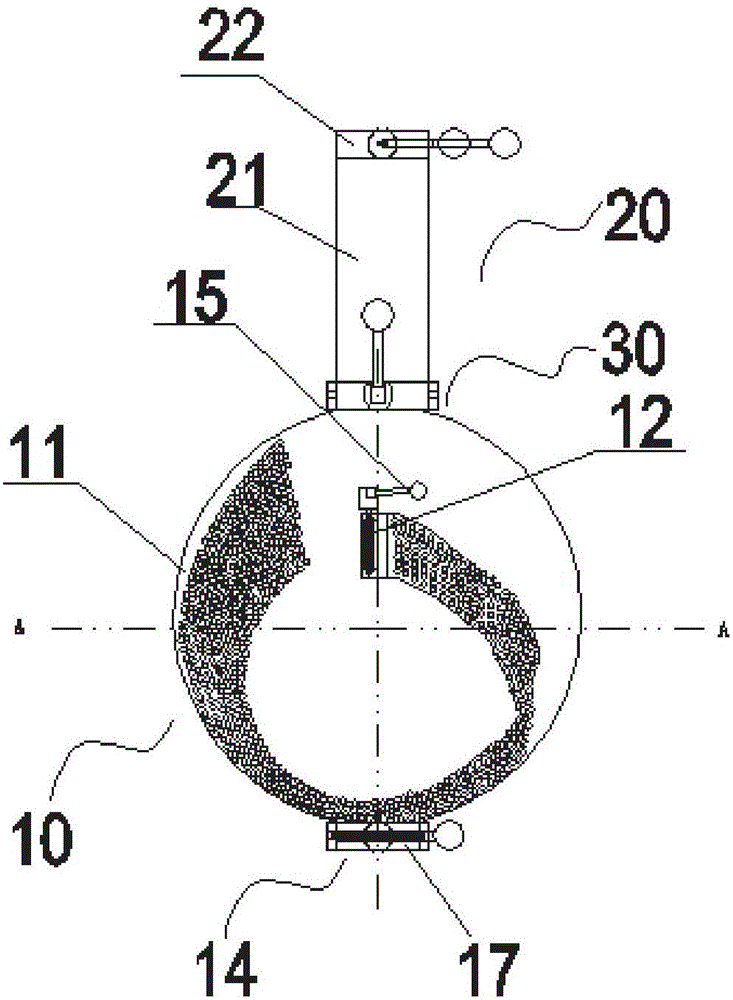

Spherical camera shield cleaning device

PendingCN107470185AEasy to cleanImprove clarityTelevision system detailsColor television detailsWater storageBristle

The invention provides a spherical camera shield cleaning device. The spherical camera shield cleaning device comprises a hemispheric cleaning cover, a handle, a rotating rod and a motor, the handle is an electric stretchable rod and is arranged outside the rotating rod in a sleeving manner, one end of the rotating rod is connected with the output end of the motor, and the other end of the rotating rod is fixedly connected with the bottom of the hemispheric cleaning cover; and the inner side of the hemispheric cleaning cover is provided with brush bristles and a water outlet hole, the water outlet hole is communicated with a water pump through a pipe, and the water pump is connected with a water storage box. The spherical camera shield cleaning device is convenient to clean, quick and safe, the cleaning effect is good, dead corners are avoided, and cost is saved.

Owner:TIANJIN ZHONGAN SHITONG TECH CO LTD

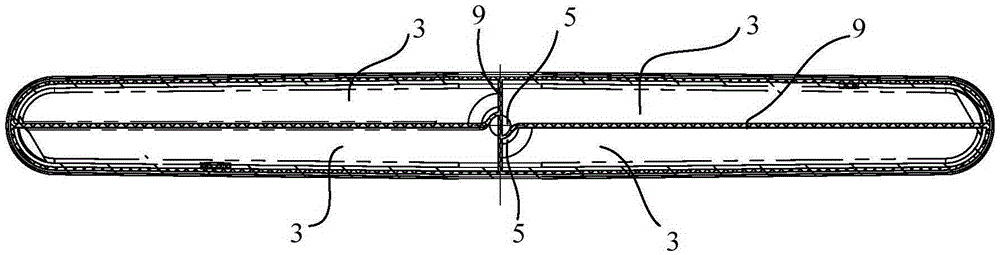

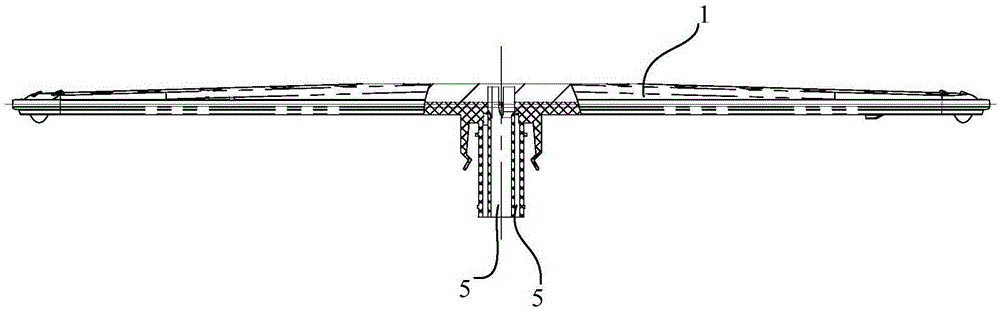

Spraying head and sprayer

ActiveCN106606341AImprove cleaning efficiencyIncreased cleaning positionsTableware washing/rinsing machine detailsSprayerBody surface

The invention discloses a spaying head and a sprayer and relates to the technical field of dish washing machines. The spraying head disclosed by the invention comprises a strip-shaped shell body, wherein spraying holes are arranged along the length direction of the shell body surface; the spraying holes are divided into at least two groups; each group of spraying holes could supply water for spraying at the same time; and different groups of spraying holes could supply water for spraying in a time-shared manner. The sprayer used for tableware washing disclosed by the invention comprises the spaying head, wherein the spraying head is installed on a fixation base; and the spraying head can be rotated relative to the fixation base. The spraying head and the sprayer disclosed by the invention are characterized in that the spraying head can carry out time-shared spraying of different groups of spraying holes, so the spraying can be controlled easily, and the water pressure does not need to be increased when the quantity of the spraying holes increases; and the sprayer comprises the spraying head and can carry out rotary spraying as well as spraying at different angles and in different rotation directions, so cleaning dead corners are reduced.

Owner:QINGDAO HAIER DISHWASHER +1

Cleaning method of nuclear fuel element grillwork stripe

InactiveCN106733907AImprove efficiencyImprove pass rateCleaning using liquidsWorking environmentCleaning methods

The invention relates to a manufacturing technique of nuclear fuel grillwork strips, in particular to a cleaning method of a nuclear fuel element grillwork stripe. A hydrocarbon cleaner serves as cleaning liquid, and the cleaning method comprises the cleaning links including primary cleaning operation, dewatering, secondary cleaning operation, third-time cleaning operation, steam bath cleaning operation and vacuum drying operation. The working efficiency of cleaning of the nuclear fuel element grillwork stripe is effectively improved, the working environment is improved, and the cleaning qualification rate of a stripe product is increased.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

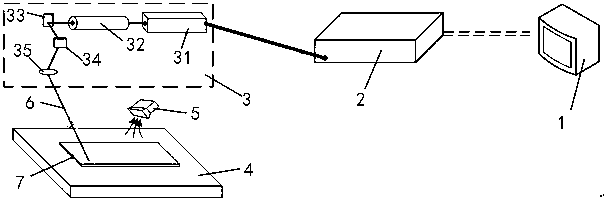

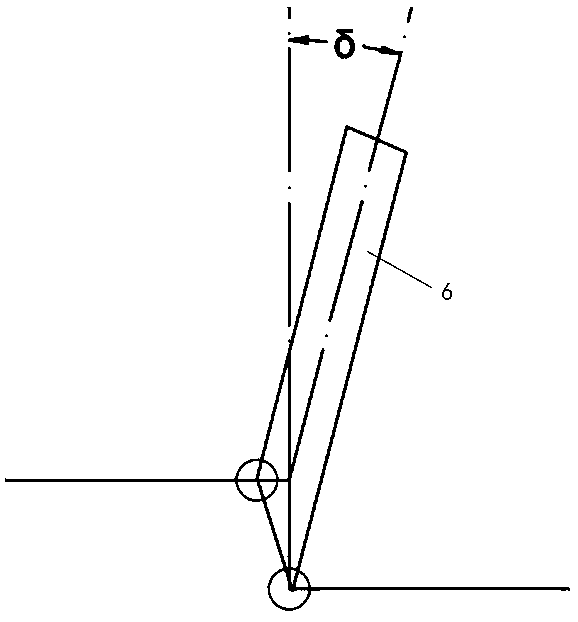

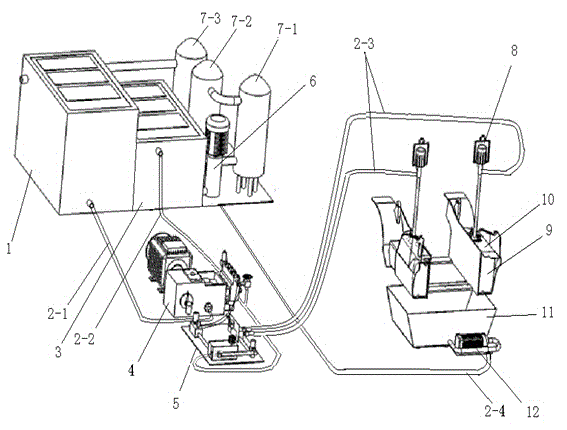

Dry type laser cleaning device and method for nondestructive inspection liquid for aluminum alloy

The invention discloses a dry type laser cleaning device and method for nondestructive inspection liquid for an aluminum alloy, and relates to the technical field of laser cleaning. The dry type lasercleaning device and method aim to solve the technical problem that in the prior art, the surface of a workpiece is prone to be damaged in the nondestructive inspection liquid clearing process. The dry type laser cleaning device comprises a controller, the controller is connected to a laser and a dust removal device, laser light emitted by the laser is irradiated on the surface of a workpiece through a laser cleaning head, the dust removal device recycles waste generated on the surface of the workpiece through a dust-absorbing bamboo joint pipe, the laser cleaning head comprises an isolator, one end of the isolator is connected to the laser, and the other end of the isolator is sequentially connected to a homogenizer, a Y galvanometer, an X galvanometer and an F lens. According to the device and the method, the laser is used for heating the nondestructive inspection liquid on the surface of the workpiece, so that the nondestructive inspection liquid can be instantly vaporized and evaporated, the damage to the workpiece is avoided, and the cleaning efficiency is high; the waste generated in the cleaning process can be synchronously recycled and treated in a concentrated mode, and the cleaning process is safe and environmentally-friendly; and various workpieces with complex surface structures can be cleaned, the number of the cleaning dead angles is small, and cleaning is thorough.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

Cleaning device for medical equipment

InactiveCN112403996AEasy to hangNot easy to impactDrying gas arrangementsCleaning using liquidsMedical equipmentProgrammable logic controller

The invention relates to the technical field of medical equipment cleaning, and discloses a cleaning device for medical equipment. The cleaning device comprises a tank body, an electromagnetic water valve and a programmable logic controller (PLC) fixed on the tank body, wherein an opening is formed in the upper end of the tank body, a cover plate is arranged at the edge of the opening, and the edge of the cover plate is symmetrically and fixedly connected with two connecting plates; the lower ends of the two connecting plates are fixedly connected with electric push rods, and the ends, away from the connecting plates, of the electric push rods are fixedly connected with the side wall of the tank body; and the lower end of the cover plate is fixedly connected with a circular ring, the edgeof the circular ring is slidably connected with the inner edge of the opening in the upper end of the tank body, and the inner side of the circular ring is transversely and fixedly connected with a connecting rod. According to the cleaning device for the medical equipment, the medical equipment can be hung in the cleaning device to be cleaned, the contact area of the medical equipment and the cleaning device is reduced, the working efficiency of the cleaning device is improved, and the medical equipment can be soaked and effectively flushed during cleaning.

Owner:贵州睿易通科技有限公司

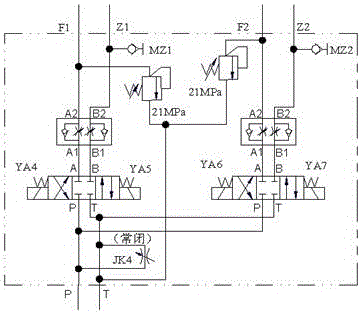

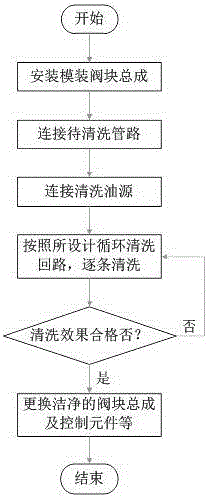

On-line cyclic cleaning process for hydraulic pipeline system

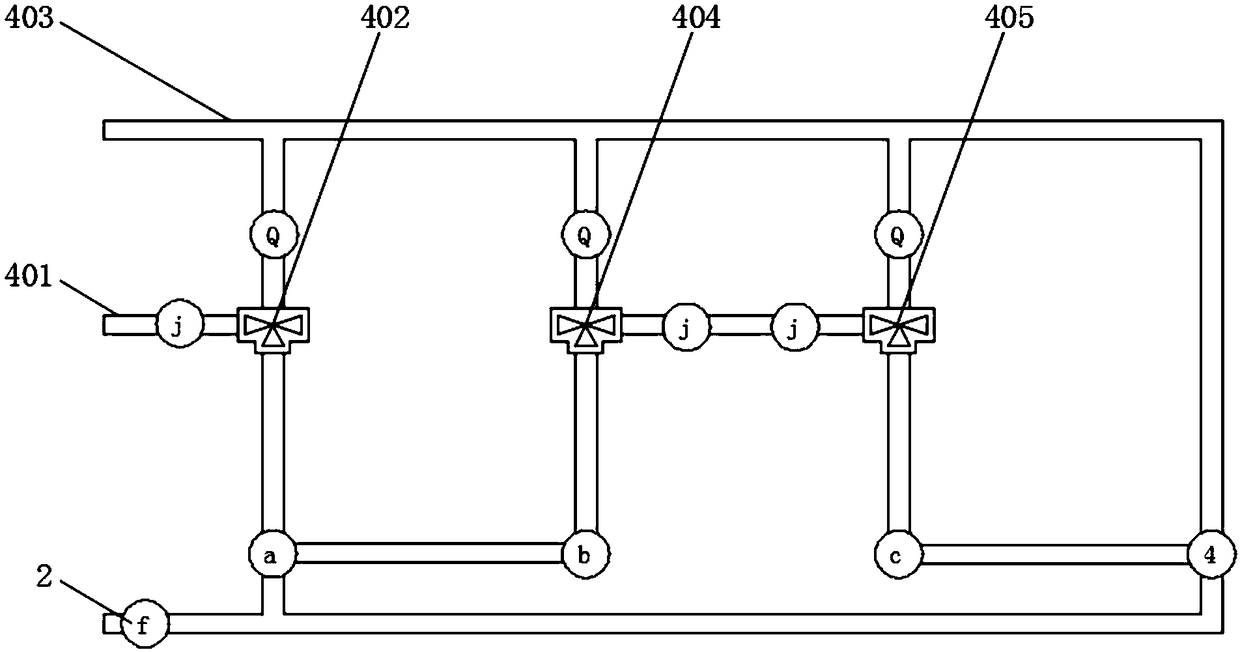

ActiveCN105964632ABest cleaning conditionsEasily turbulent flowHollow article cleaningMock upsEngineering

The invention discloses an on-line cyclic cleaning process for a hydraulic pipeline system and belongs to pipeline cleaning technologies in the field of hydraulic transmission. The on-line cyclic cleaning process for the hydraulic pipeline system aims at achieving the technical effect that an on-line cyclic cleaning technology for complex, long and large hydraulic pipeline systems is provided so that cleaning quality and efficiency can be improved. According to the technical scheme, the on-line cyclic cleaning process comprises the steps of 1, firstly, switching off a hydraulic power pack, an actuator, a control valve piece and a real valve block assembly; 2, designing a cleaning loop; 3, connecting pipelines different in pipe diameter in sequence from thick to thin; 4, designing a mock-up valve block assembly; 5, connecting the mock-up valve block assembly to to-be-cleaned loops; 6, connecting the to-be-cleaned loops to a cleaning oil source; 7, cleaning each to-be-cleaned loop; and 8, checking whether the cleaning effect is qualified or not, wherein if the cleaning effect is qualified, a valve block assembly is replaced with a clean valve block assembly, the control valve piece and the real valve block assembly are replaced, and the cleaning work is completed; and if the cleaning effect is not qualified, the cleaning process in step 7 is repeated till the cleaning effect is qualified. The on-line cyclic cleaning process is applied to cleaning of hydraulic pipelines.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

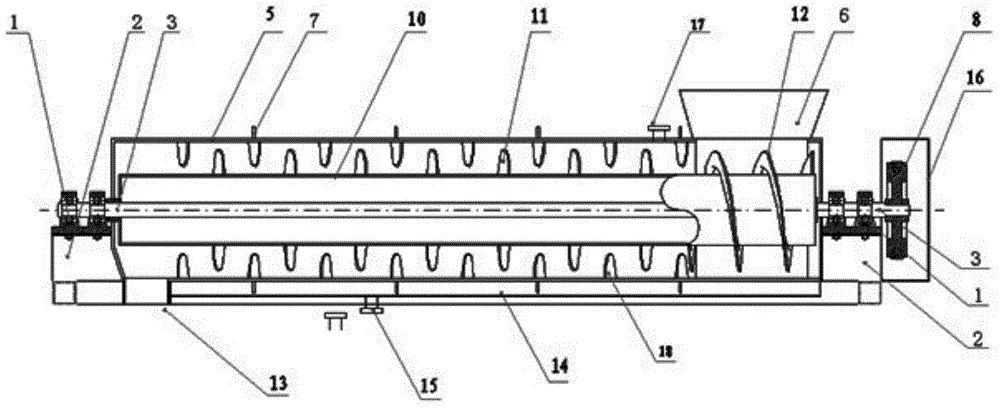

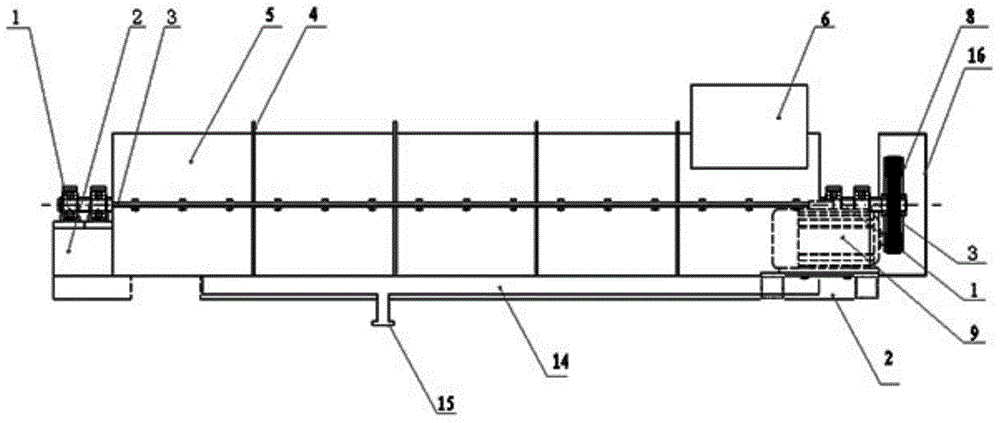

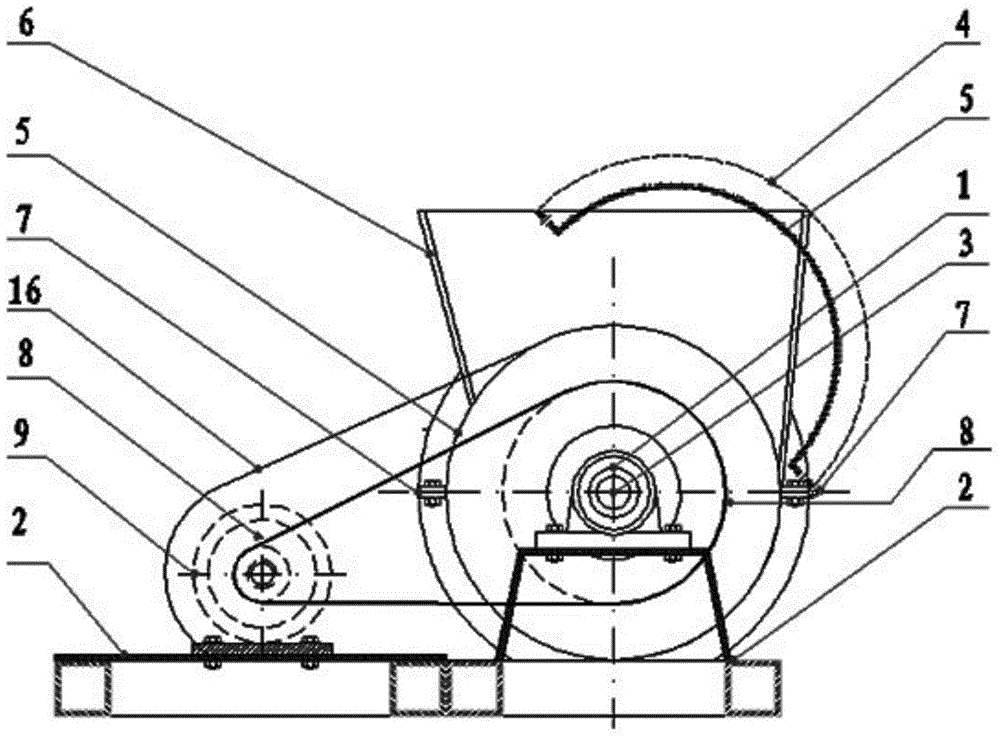

Frictional cleaning label-remover for plastic films

InactiveCN104475374AImprove cleaning effectReduce cleaning dead angleCleaning using toolsCleaning using liquidsThin membranePlastic film

The invention discloses a frictional cleaning label-remover for plastic films, comprising an underframe and an outer cylinder disposed on the same. An inner cylinder is disposed within the outer cylinder. A spindle penetrating the two ends of the outer cylinder is disposed within the inner cylinder. Two ends of the spindle are fixed to the underframe through a plurality of bearings. One end of the spindle is further provided with a belt pulley and a main motor fitting each other. One end of the outer cylinder is provided with a water inlet and a feed opening; meanwhile, the other end of the outer cylinder is further provided with a discharge opening. The bottom end of the underframe is provided with a collecting and residue-discharging channel and a pipeline flange fitting the collecting and residue-discharging channel. The outer wall of the inner cylinder is provided with a plurality of cleaning main teeth and a spiral vane fitting the feed opening. The inner wall of the outer cylinder is provided with a plurality of cleaning auxiliary teeth. The frictional cleaning label-remover for the plastic film has the advantages that cleaning effect is greatly enhanced by modifying a cleaning mode, cleaning dead corners are narrowed, label removal rate is increased, multiple contacts engage in friction at a time, material cleaned needs no secondary frictional cleaning, and cleaning time is greatly saved.

Owner:宁波高新区科宁机械设备有限公司

Cotton woven fabric cleaning device

InactiveCN109162043AReduce cleaning dead angleExtended wash rangeMechanical cleaningPressure cleaningBiochemical engineeringCotton material

The invention discloses a cotton woven fabric cleaning device comprising a cleaning tank containing cleaning liquid. A first guiding roller, a second guiding roller and a third guiding roller are arranged successively in the cleaning tank. A first roller brush in contact with the top surface of cotton woven fabric is arranged between the first guiding roller and the second guiding roller; and a second roller brush in contact with the bottom surface of the cotton woven fabric is arranged between the second guiding roller and the third guiding roller. Besides, a first flushing pipe is also arranged in the cleaning tank; and a rotating motor is arranged at the outer side of the cleaning tank. A first arc-shaped groove using the rotating shaft center of the rotating motor as the circle centeris formed in one side of the cleaning tank and is ranged above the cleaning tank; a second arc-shaped groove corresponding to the first arc-shaped groove is formed in the other side of the cleaning tank; one end of the first flushing pipe passes through the first arc-shaped groove and is connected with the rotating shaft of the rotating motor by a connecting rod; and the other end of the first flushing pipe passes through the second arc-shaped groove and is connected with a limiting block. The cotton woven fabric cleaning device has characteristics of high cleaning efficiency and good cleaningeffect.

Owner:湖州南浔维意纺织有限公司

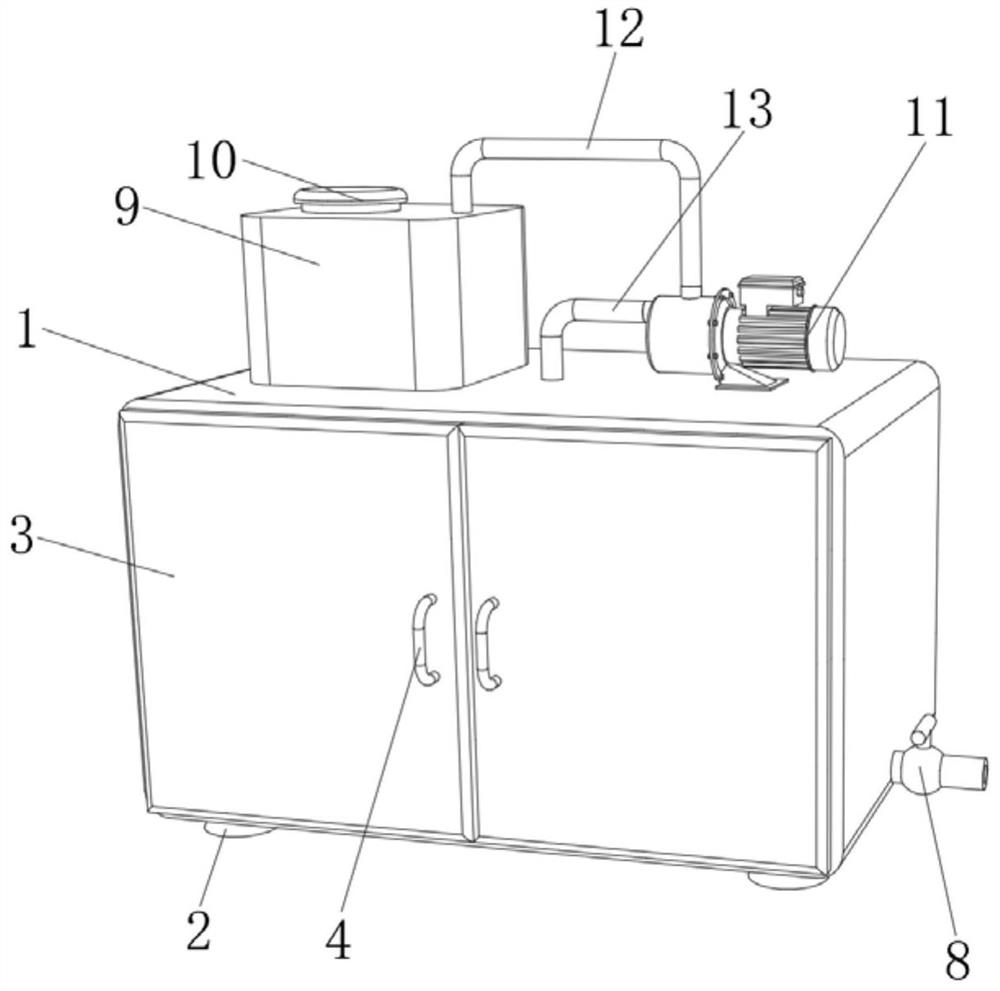

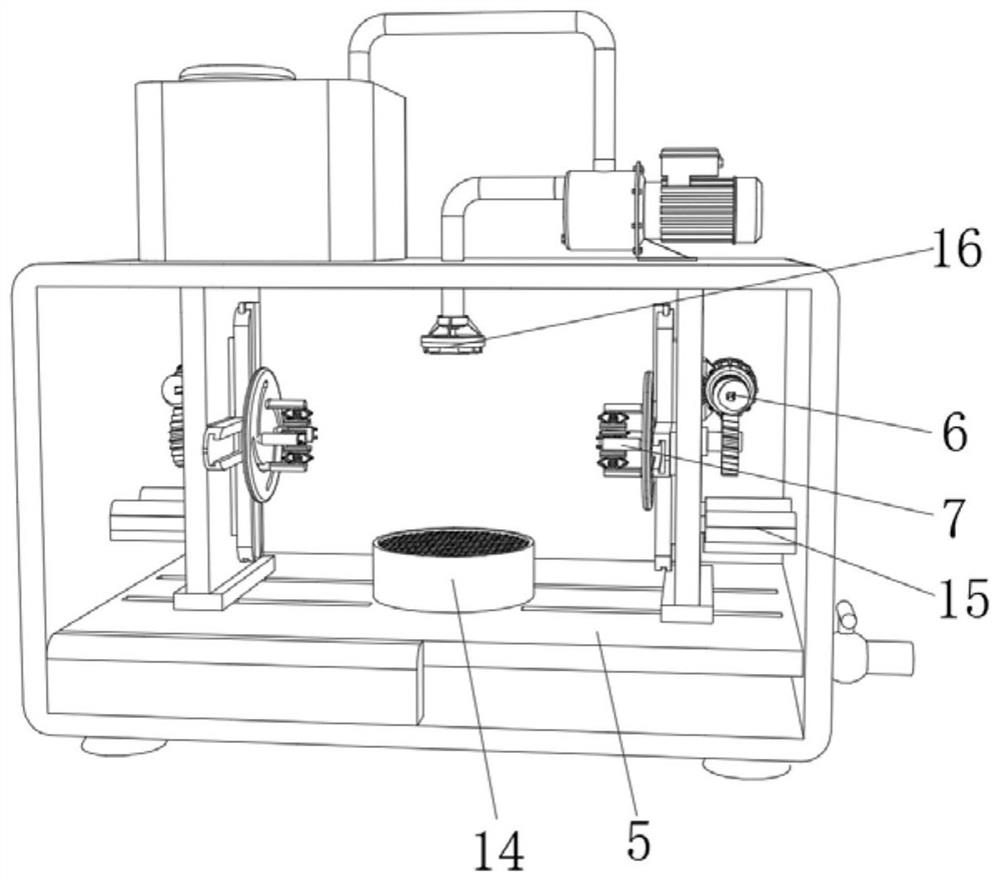

Rotary spraying cleaning machine for machine parts

InactiveCN106623188ANovel structureExpand the scope of cleaningCleaning using liquidsMachine partsSprayer

The invention discloses a rotary spraying cleaning machine for machine parts. The rotary spraying cleaning machine for the machine parts comprises a cleaning room, a rotary rod, a cleaning sprayer and a transmission shaft. A first motor is installed at the top end of the cleaning room, and a water storing room is installed on the right side of the first motor; the rotary rod is fixed to the bottom end of the first motor, and a water guiding pipe is installed on the inner side of the rotary rod; the cleaning sprayer is inlaid in the inner wall of the rotary rod; an observing opening is formed in the right side surface of the cleaning room, and a water collecting trough is arranged on the bottom side of the cleaning room; a spraying base is fixed to the middle of the water collecting trough, and a fixing clamp is inlaid in the outer wall of the spraying base; the transmission shaft is installed below the fixing clamp and connected with a second motor; a waste water treatment trough is arranged below the water collecting trough; and an air blower is fixed to the inner side of the cleaning sprayer. The rotary spraying cleaning machine for the machine parts is simple and novel in structure, and the cleaning range of the cleaning sprayer is increased through opposite rotating between the rotary rod and the transmission shaft.

Owner:江西宜人家食品有限公司

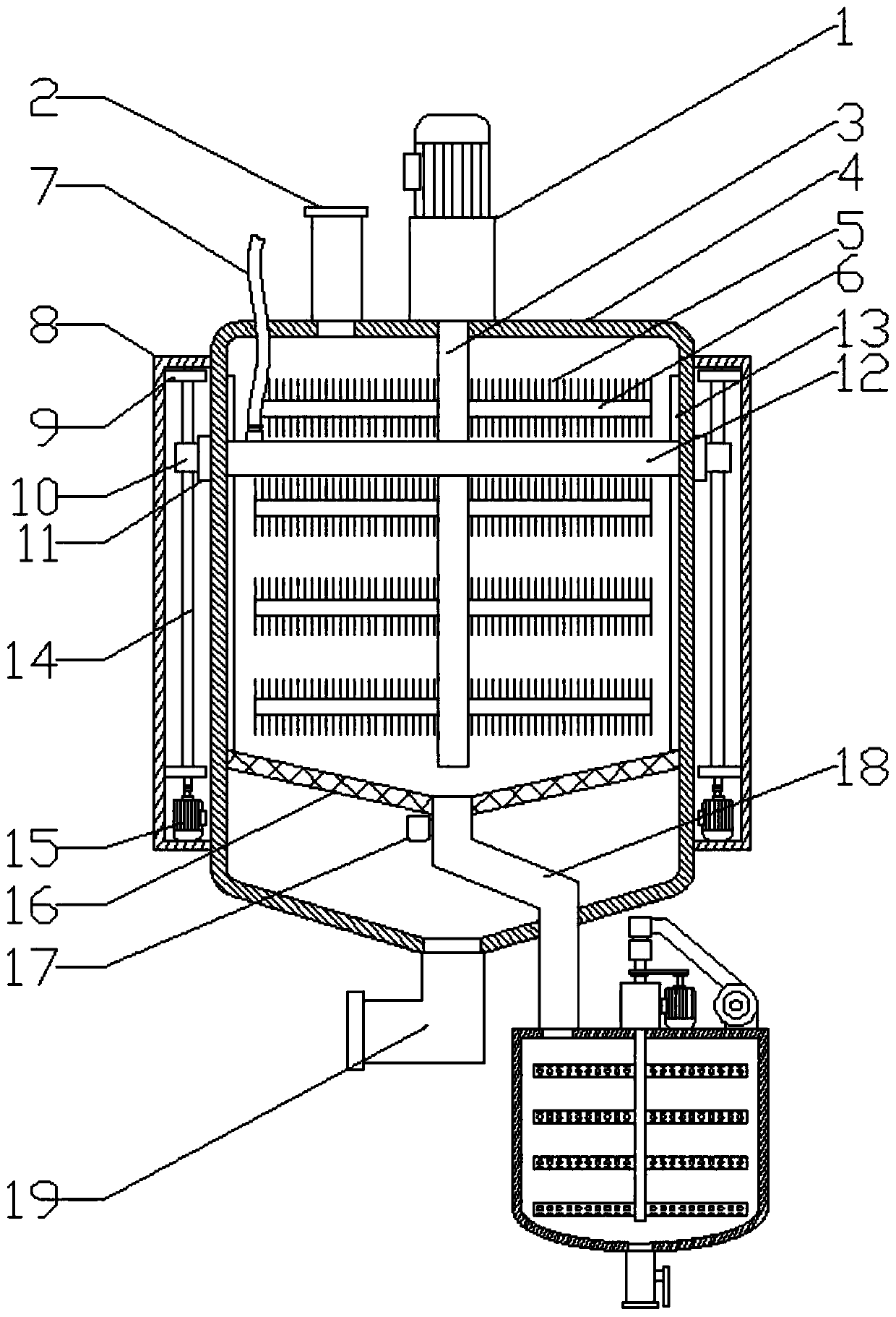

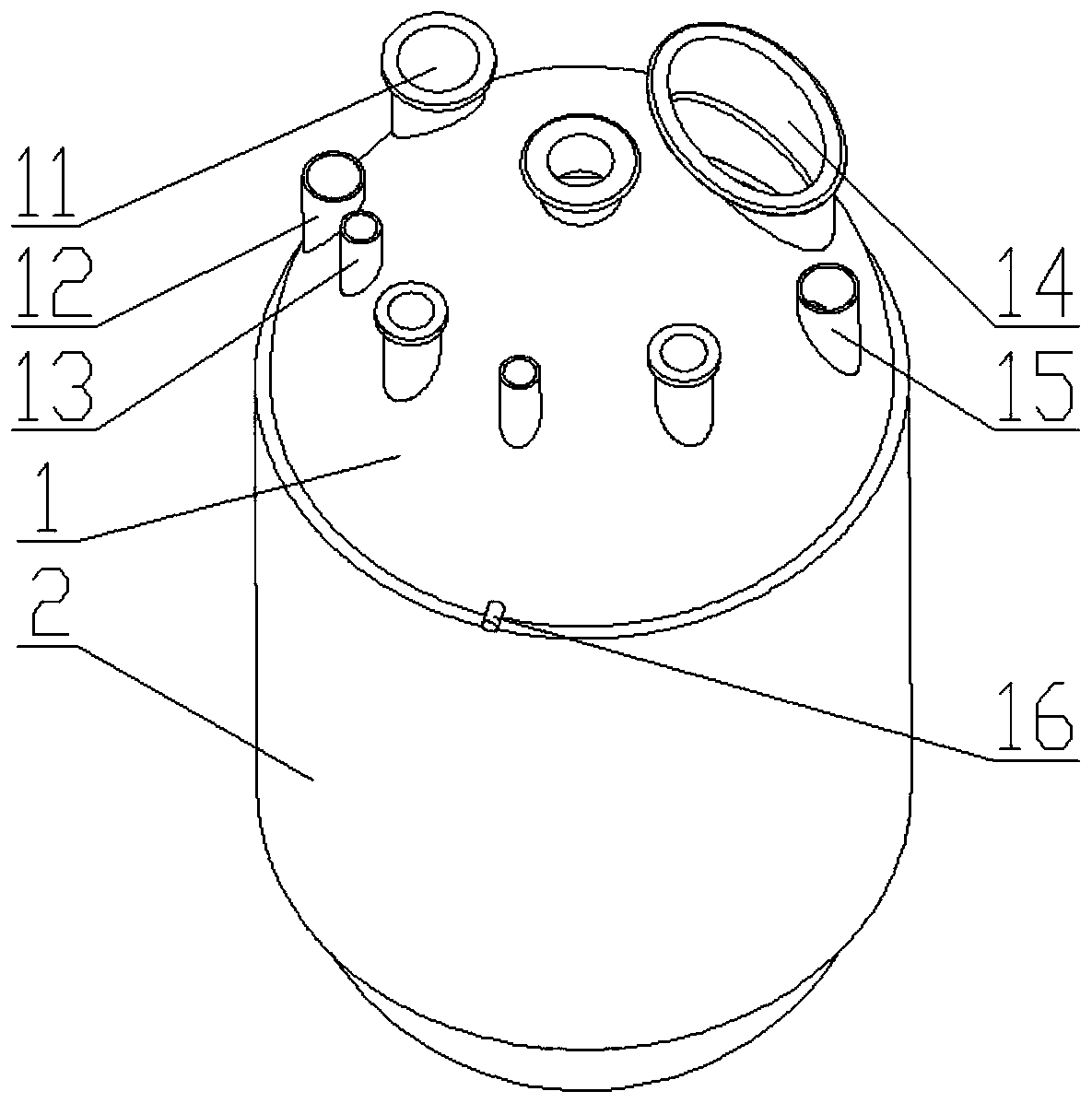

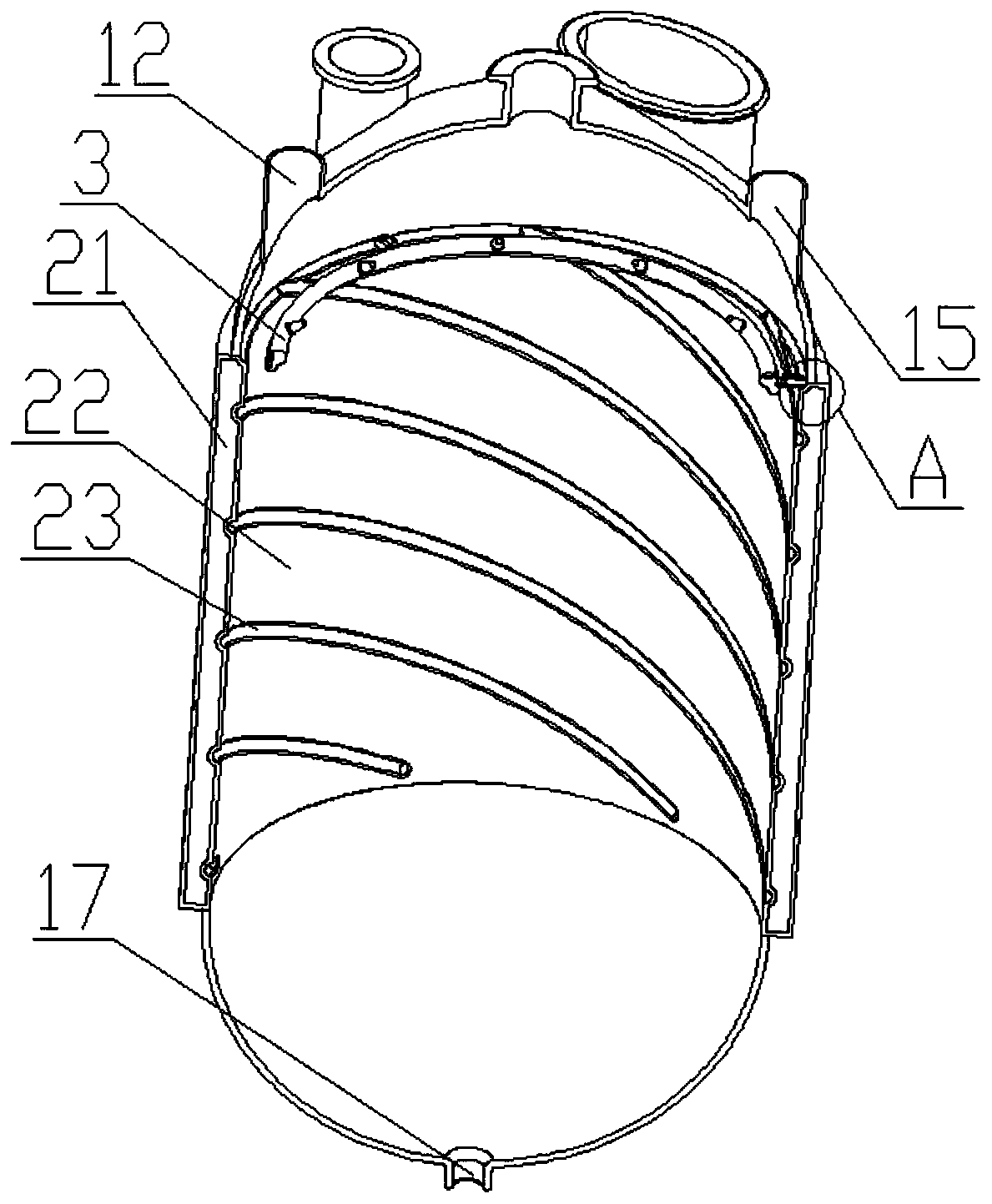

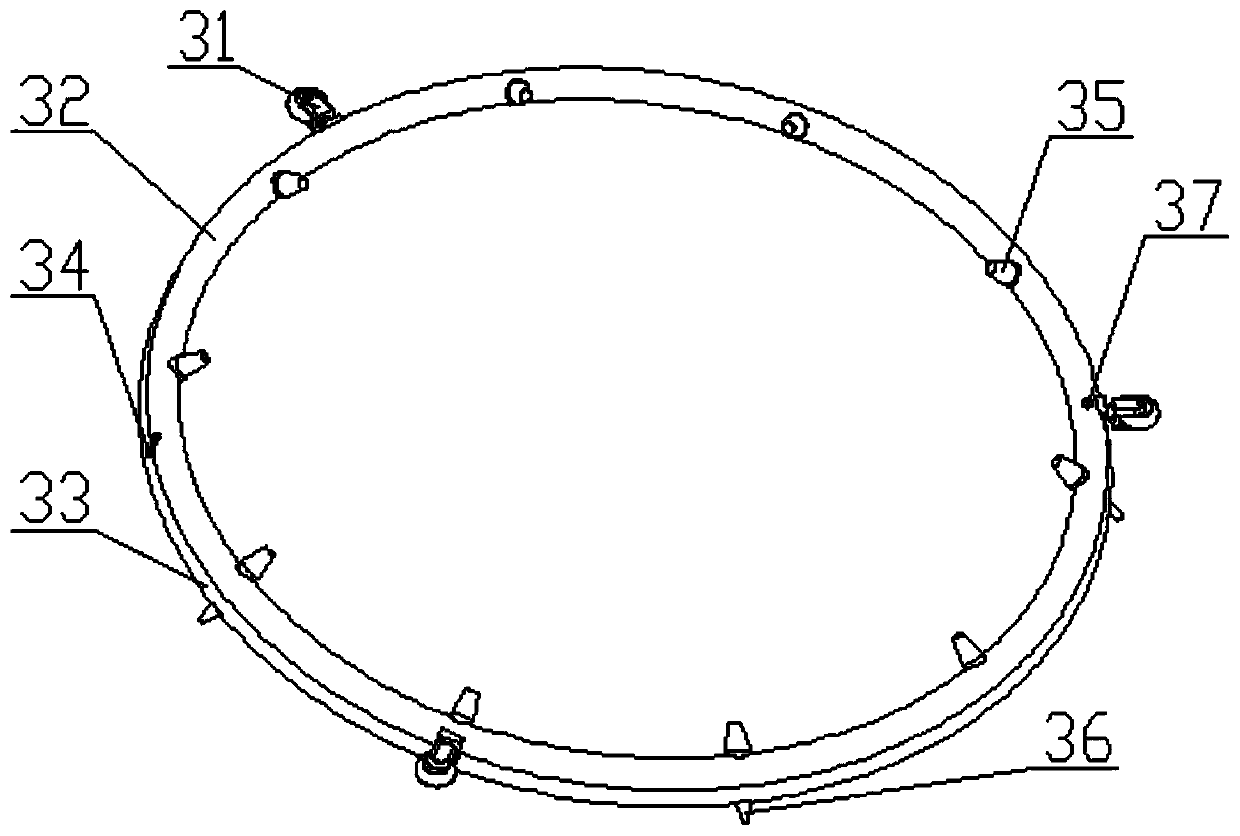

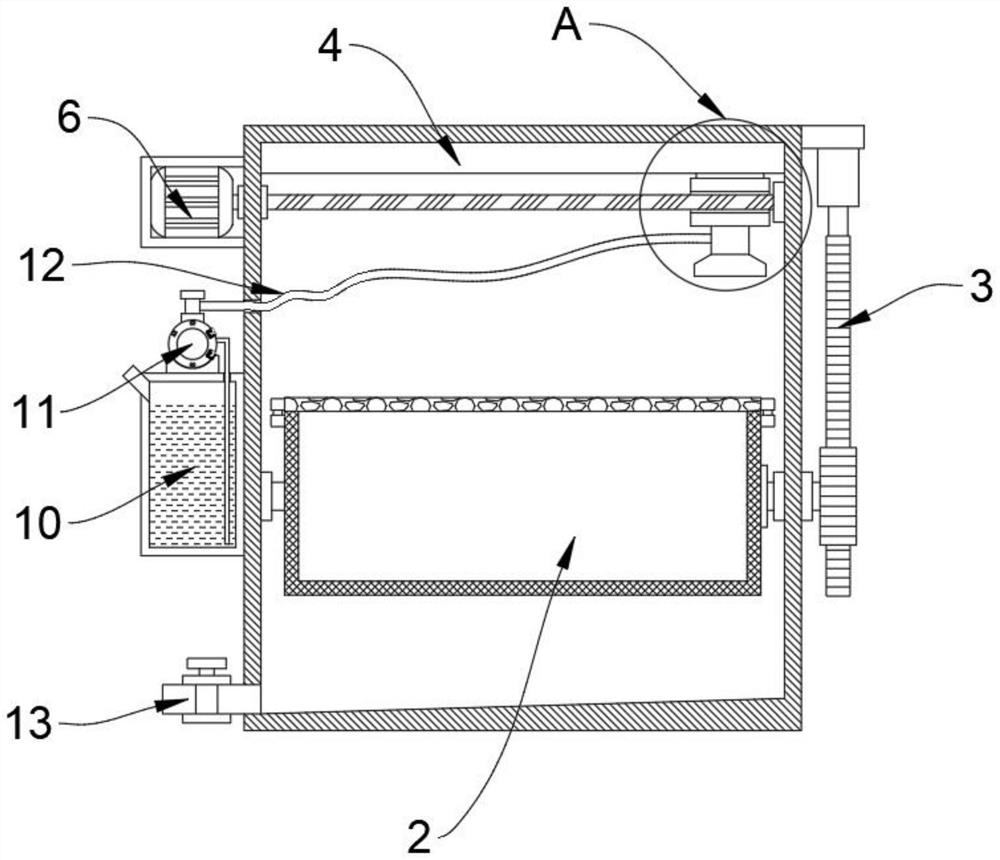

Reaction kettle and cleaning method thereof

InactiveCN109772244AFast cleaningReduce cleaning dead angleHollow article cleaningChemical/physical/physico-chemical stationary reactorsNozzleChemical engineering

The invention discloses a reaction kettle which comprises a tank body and an upper cover connected to the tank body. A feeding inlet, a liquid inlet and a maintaining opening are formed in the upper cover, the tank body comprises a heating wall, a heating sleeve and a tank bottom connected to the bottom of the heating wall, a discharging outlet is formed in the tank bottom, and the heating sleevesleeves the heating wall; the reaction kettle further comprises a cleaning device, a left pipe inlet and a right pipe inlet are symmetrically arranged on the upper cover, and sealing covers are arranged at the left pipe inlet and the right pipe inlet; the heating wall is provided with at least three spiral heating concave rails allowing the cleaning device to be positioned and slide at equal intervals; according to the reaction kettle and the cleaning method thereof, the reaction kettle is cleaned through an upper track nozzle and a lower track nozzle on the cleaning device, meanwhile, the cleaning device rotates when lifted through the spiral heating concave rails, and the effect of cleaning different angles of the inner wall of the reaction kettle is achieved.

Owner:南昌汇达知识产权有限公司

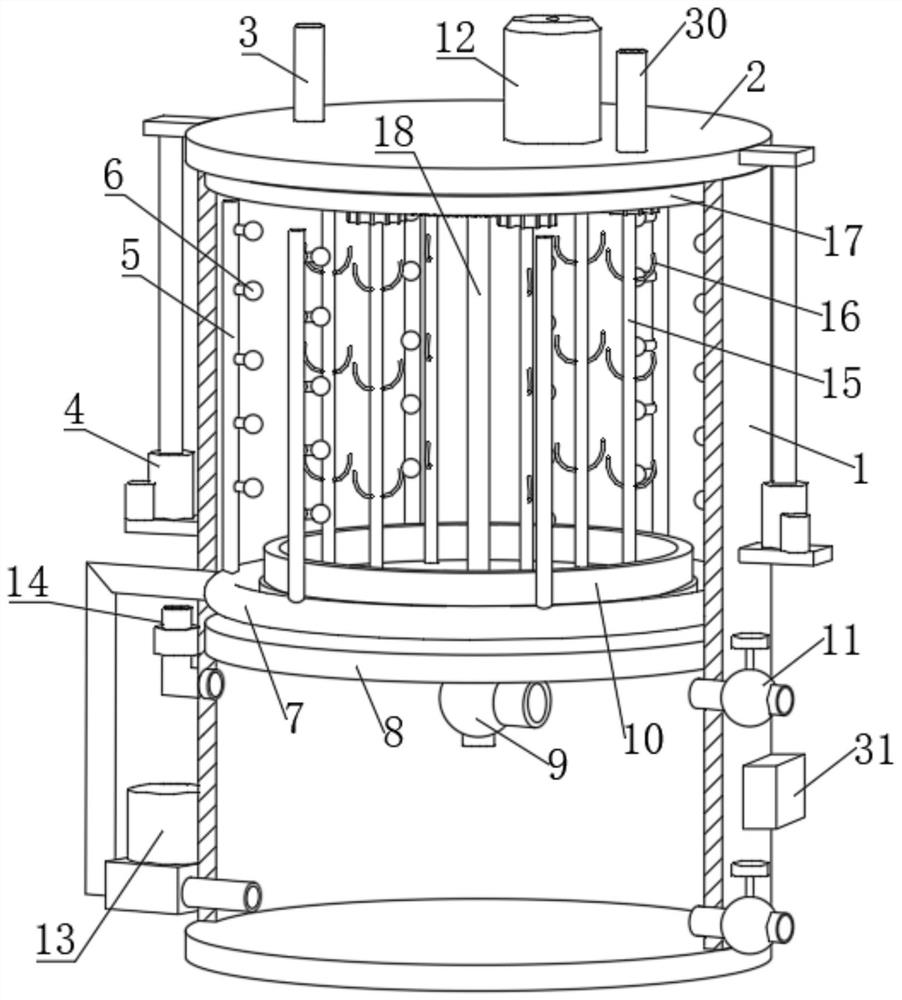

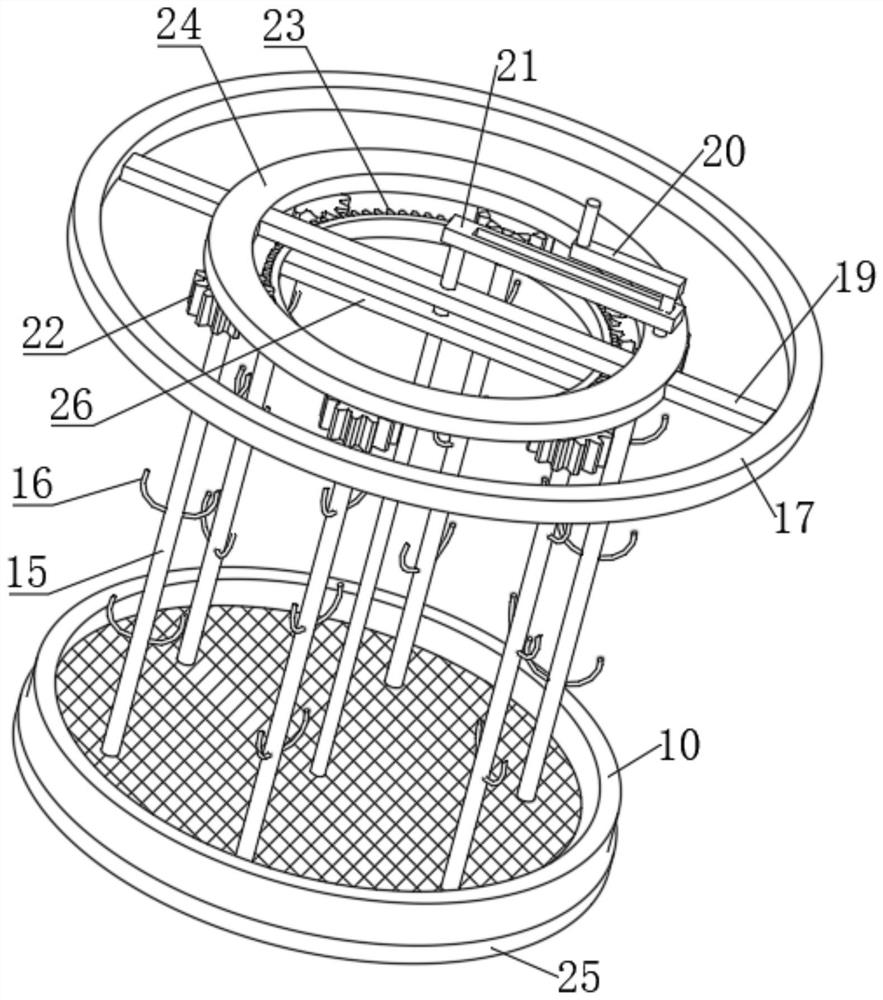

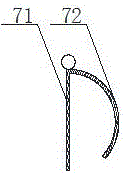

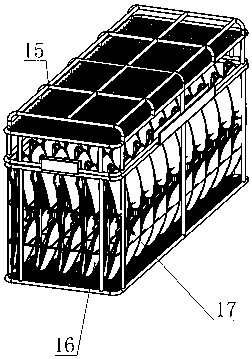

A kind of rotating glasses cleaning equipment and its cleaning basket

ActiveCN103913855BImprove cleaning efficiencyBest tangential flushing forceSpectales/gogglesCleaning using liquidsEngineeringMechanical engineering

Owner:GUANGZHOU CAIBIAO 3D GLASSES

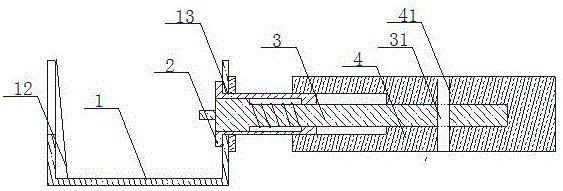

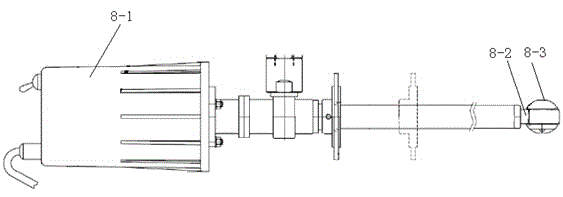

Turbine handpiece provided with needle locker

The invention discloses a turbine handpiece provided with a needle locker, which comprises a support, an ejector needle, a needle guard and a sleeve. Mutually adaptive through holes are formed in the radial direction in the tail end of the ejector needle and the sleeve; a fixing needle is inserted into the through holes for fixing the ejector needle and the sleeve, and comprises a fixing part and a limiting arc, the fixing part is a cylinder, the limiting arc is an arc connected with one end of the fixing part, and the arc is matched with the outer surface of the sleeve. According to the invention, the ejector needle and the sleeve are connected by utilizing the fixing needle, all that is needed for connection is to align the through hole in the ejector needle to the through hole in the sleeve, and then insert the fixing part of the fixing needle into the through holes, the installation is convenient and simple, and the fixation is relatively stable, so that conditions of misplacement and ejector needle deflection are avoided; the ejector needle comprises the limiting arc, the fixing part inserted into the through holes can sleeve the sleeve to prevent the fixing needle from falling off and causing a potential safety hazard; a needle groove matched with the limiting arc is arranged on the sleeve and can hide the limiting arc in the needle groove without influencing the assembly of other parts in the handpiece.

Owner:李艳霞

Countercurrent sugar washing machine

PendingCN111482407AFully desugared from the surfaceHigh in sugarConfectionerySweetmeatsRinse waterEnvironmental engineering

The invention discloses a countercurrent sugar washing machine in the field of preserved fruit processing devices. The countercurrent sugar washing machine comprises at least one stage of conveying and cleaning assembly, wherein one end of each stage of conveying and cleaning assembly is provided with a feed port, the other end of each stage of conveying and cleaning assembly is provided with a discharge port, and the discharge port of the previous stage is connected with the feed port of the next stage; each conveying and cleaning assembly comprises a cleaning water tank with a U-shaped crosssection, a conveying mechanism capable of conveying materials from the corresponding feed port to the corresponding discharge port is arranged in the cleaning corresponding water tank, the cleaning water tanks are obliquely arranged, the position of one end of each feed port of the corresponding cleaning water tank is lower than that of one end of the corresponding discharge port of the corresponding cleaning water tank, a spraying pipe is arranged in each cleaning water tank, and an overflow water outlet mechanism is arranged at the low end of each cleaning water tank. The device washes sugar in a countercurrent mode, the sugar washing efficiency is high, and washing water can be repeatedly used. The countercurrent sugar washing machine is specially used for preserved fruit processing.

Owner:JIANGSU KAIYI INTELLIGENT SCI & TECH

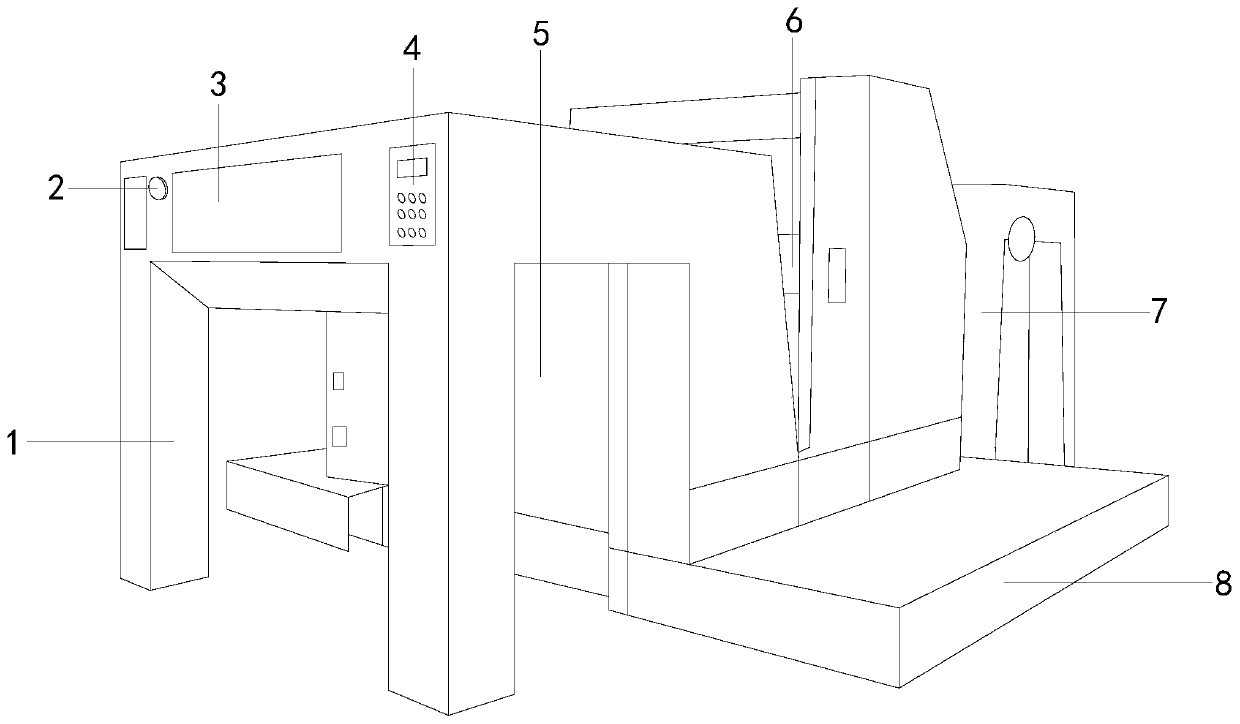

Energy-saving type opposite-opened four-color printing machine

The invention discloses an energy-saving type opposite-opened four-color printing machine. The structure of the energy-saving type opposite-opened four-color printing machine comprises a frame, a master switch, a display screen, an operation board, a conveying frame, a printing roller, an ink box and a base. The energy-saving type opposite-opened four-color printing machine has the beneficial effects that the problem is solved by arranging an ink cleaning device on the printing roller; the ink cleaning device flushes and removes excessive ink on the printing roller through a claw ring device and a flusher on the structure; the claw ring device can prevent the ink from being attached to a disc body due to interference of high intensity airflow in the ink cleaning process; the flusher flushes the surface and the gap of the printing roller by using a compressed gas; by using slide grooves whose structures correspond to each other, the flusher can realize up-and-down sliding deviation to change the washing range so as to reduce washing dead corners; and by removing the excessive ink on the printing roller to reduce the failure rate and the loss of paper products, the purpose of savingenergy is achieved.

Owner:陈益航

Washing device for recycling sterilization of medical apparatus

InactiveCN107570472AThe function of sterilization and disinfection is weakenedIncrease the function of sterilization and disinfectionLavatory sanitoryCleaning using liquidsElectricityProcess engineering

The invention provides a washing device for recycling sterilization of medical apparatus, and relates to the technical field of medical machinery and equipment. The washing device comprises a washingand disinfecting tank and a washing fluid arranged in the washing and disinfecting tank and further comprises a liquid purifying tank, a circulating pump and a circulating pipeline. The circulating pipeline leads the washing liquid into the liquid purifying tank for being purified, and the washing liquid is conveyed into the washing and disinfecting tank again through the circulating pump. The liquid purifying tank is internally provided with a filter plate and a discharge generator. The discharge generator is arranged below the filter plate. The discharge generator comprises a power supply part, a cathode and an anode, wherein the cathode and the anode are electrically connected with the power supply part. The washing liquid output from the bottom of the liquid purifying tank comprises hydrogen peroxide produced by streamer discharge in the washing liquid through the voltage applied by the power supply part to the cathode and the anode. By means of the technical scheme, the problems that with long-term using of the washing fluid, the sterilization and disinfection functions of the washing liquid are gradually weakened, even the washing fluid is recycled and reused, and the medicalapparatus cannot be qualified in sterilization are solved.

Owner:弘毅天承知识产权股份有限公司

High-pressure three-dimensional water-jet oil tank cleaning device

ActiveCN104826844AMeet cleanliness requirementsEasy to cleanHollow article cleaningForeign matterSlag

The invention provides a high-pressure three-dimensional water-jet oil tank cleaning device. The high-pressure three-dimensional water-jet oil tank cleaning device comprises a cleaning device and a blow-drying device, wherein the cleaning device comprises a clean water tank, the outlet of the clean water tank is connected with a plunger pump inlet through a water outlet pipe, the outlet of the plunger pump is connected with a hydraulic control loop, the outlet of the hydraulic control loop is connected with a high-pressure three-dimensional rotating spray nozzle arranged in an oil tank through a high-pressure water supply pipe; the blow-drying device comprises an air gun and an electromagnetic valve arranged on the air inlet pipe of the air gun, a switch is arranged on the handle of the air gun and the switch is connected with the electromagnetic valve through a control circuit. The device can simultaneously complete the cleaning and blow-drying of the oil tank, foreign matters such as oxide scales, steel balls and welding slags are taken away by using high-pressure water flows, then the oil tank is blow-dried after cleaning is completed, the requirement on the cleanness of the oil tank is satisfied, the water scale caused by residual cleaning solution is reduced, the working conditions of operators are greatly improved and the occupational injuries of the operators are effectively avoided.

Owner:ANHUI HELI CO LTD

Magnetic expansion type cleaning device for variable-diameter pipeline

ActiveCN113458100AGuaranteed cleaning effectReduce wasteHollow article cleaningProcess engineeringMechanical engineering

The invention discloses a magnetic expansion type cleaning device for a variable-diameter pipeline, and belongs to the field of cleaning. Through the arrangement of an extension variable-diameter barrel, when a variable-diameter position is cleaned, the extension variable-diameter barrel is expanded outwards and attached to the inner wall of the variable-diameter position through attraction of an electrified electromagnetic clamp at the variable-diameter position, the cleaning device can adapt to the change of the inner diameter of the variable-diameter position of the pipeline, the cleaning effect of the variable-diameter position of the pipeline is effectively guaranteed, and compared with the prior art, the situation that cleaning dead corners appear at the position is obviously reduced, and in addition, and through the cooperation of a flexible pipe, all or most of introduced water for cleaning can only overflow or be sprayed from the extension variable-diameter barrel which extends outwards and expands outwards, so that the waste of water resources is remarkably reduced.

Owner:南通江涌投资开发有限公司

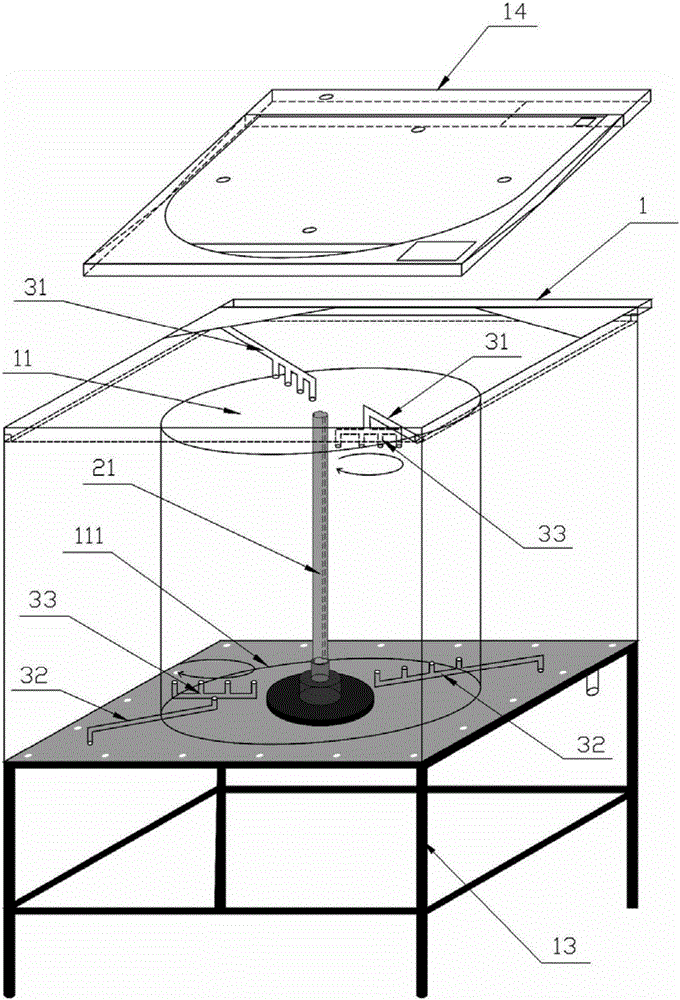

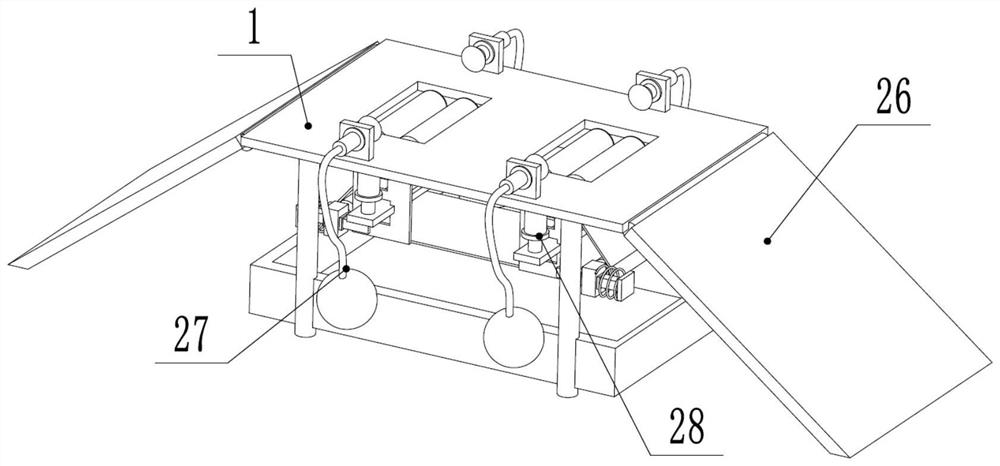

Novel horizontal glasses cleaning and drying system

InactiveCN108693643AEasy to cleanWash thoroughlySpectales/gogglesDrying gas arrangementsControl systemMetal

The invention discloses a novel horizontal glasses cleaning and drying system. The system is formed by a mechanical system and a control system. The mechanical system comprises a glasses placement framework, a transmission system, a cleaning system, a spray system (1) and a sheet metal structure (21). The glasses placement framework and the transmission system are horizontally placed in the sheetmetal structure (21). Through adopting the above scheme, by using the glasses placement framework and the transmission system which are horizontally placed in the sheet metal structure (21) and the control system of autonomous research and development, a plurality of glasses can be cleaned at one time and a batch cleaning demand is satisfied. After the glasses in a previous cleaning basket are cleaned, the cleaning basket where the glasses to be cleaned are placed is replaced so that a time interval between machine pauses is reduced and glasses cleaning efficiency is increased. The size of a whole machine is reduced and an occupied space is small.

Owner:深圳市恒创宝莱科技有限公司

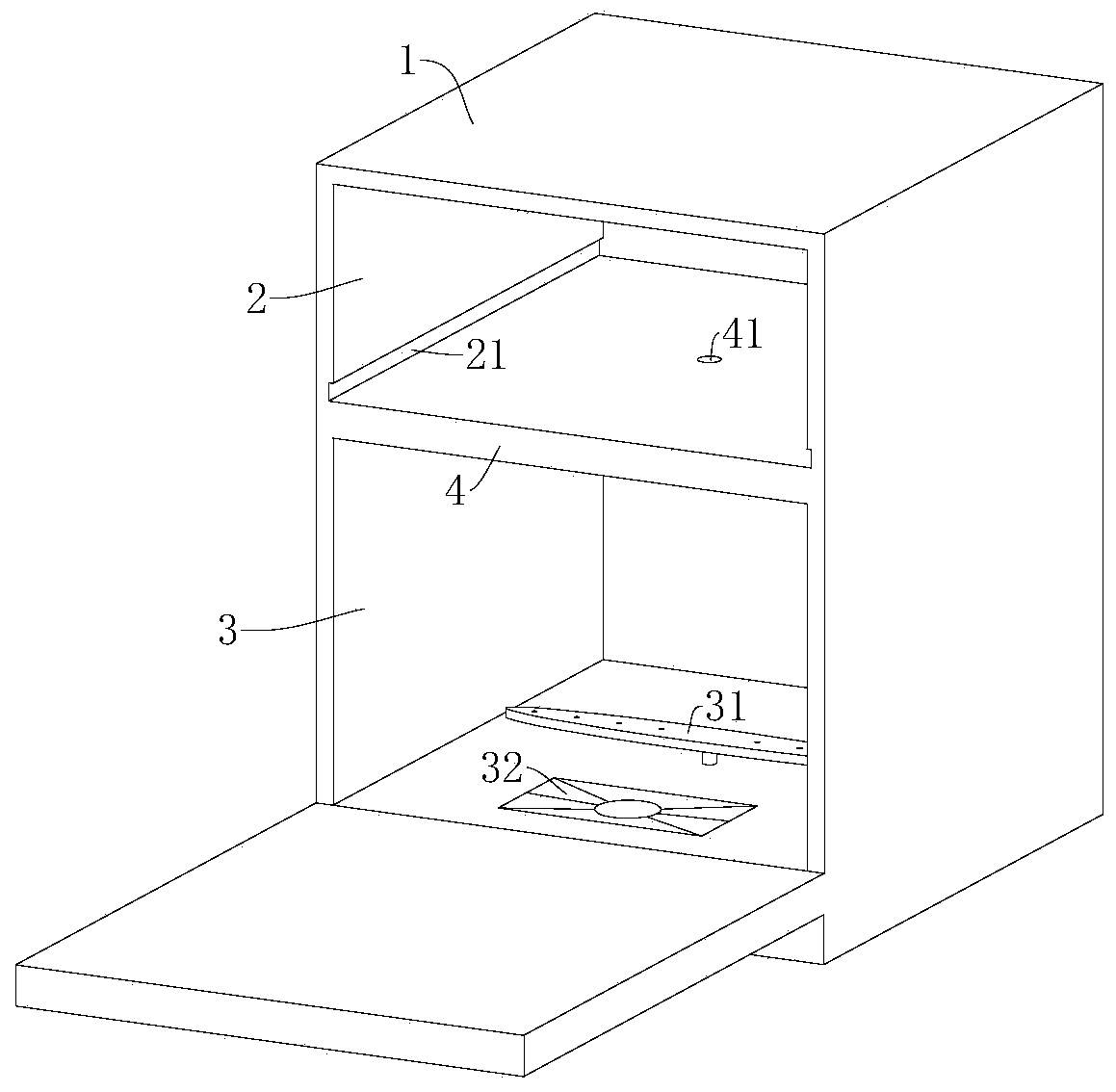

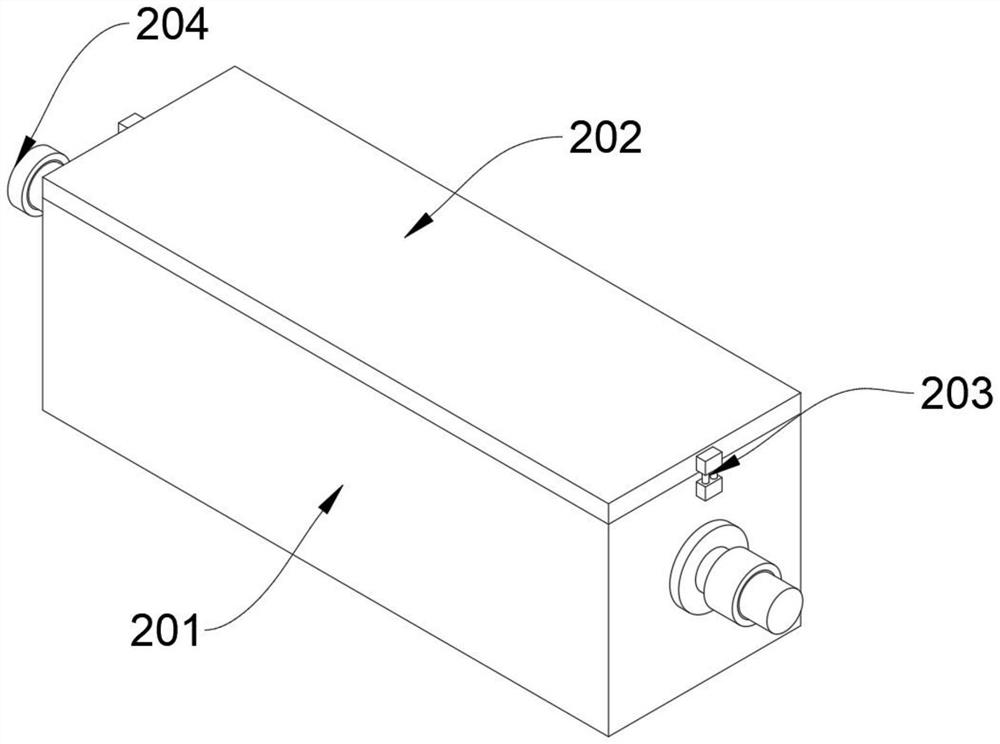

Dish washing machine

ActiveCN111067448AEasy to cleanEasy to collect emissionsTableware washing/rinsing machine detailsKitchen equipmentProcess engineeringMechanical engineering

The invention provides a dish washing machine. The dish washing machine comprises a shell which comprises a partition plate in the shell and is divided into a first chamber through the partition plate, and a cleaning tank which is supported on the partition plate and used for containing fruits and vegetables, comprises a matching part detachably connected with the shell and is used for containingand cleaning fruits and vegetables, so that the fruits and vegetables are soaked and washed in the cleaning tank. Grease and silt on fruits and vegetables remain in the cleaning tank. After a user uses the dish washing machine, the user only needs to detach the cleaning tank, so that the cleaning tank and the dish washing machine shell are separated from each other, the cleaning tank is independently cleaned, and the interior of the first chamber does not need to be complexly cleaned. Due to the fact that the cleaning tank is detached independently, cleaning dead corners are greatly reduced, cleaning is more convenient for a user, and user experience is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Zipper head outer surface cleaning device

InactiveCN114029274AIncrease the cleaning areaReduce cleaning dead angleCleaning using liquidsSurface cleaningSprayer

The invention discloses a zipper head outer surface cleaning device, and relates to the field of zipper head production. The device comprises a cleaning box, a cleaning cylinder and a driving mechanism, the driving mechanism is arranged on one side of the cleaning box, a hose is installed at the output end of a water pump, a spray head is connected to the other end of the hose, a sliding block is arranged in a sliding rail, a moving block is installed at the bottom of the sliding block, a screw is arranged in the moving block, one end of the screw is rotationally connected with the inner wall of the cleaning box, and the other end of the screw extends outwards and is connected with a screw motor. According to the cleaning device, the contact area between the cleaning device and cleaning water is increased through the driving mechanism, so that cleaning dead corners are reduced, the cleaning effect is further improved, and the cleaning effect is enhanced; and meanwhile, the arranged screw motor drives a single spray head to transversely move back and forth, so that investment of too many sprayers is reduced, investment cost of the device is reduced, the cleaning range of the sprayers is guaranteed, and the zipper head is cleaned more thoroughly.

Owner:萍乡市合兴机械五金科技有限公司

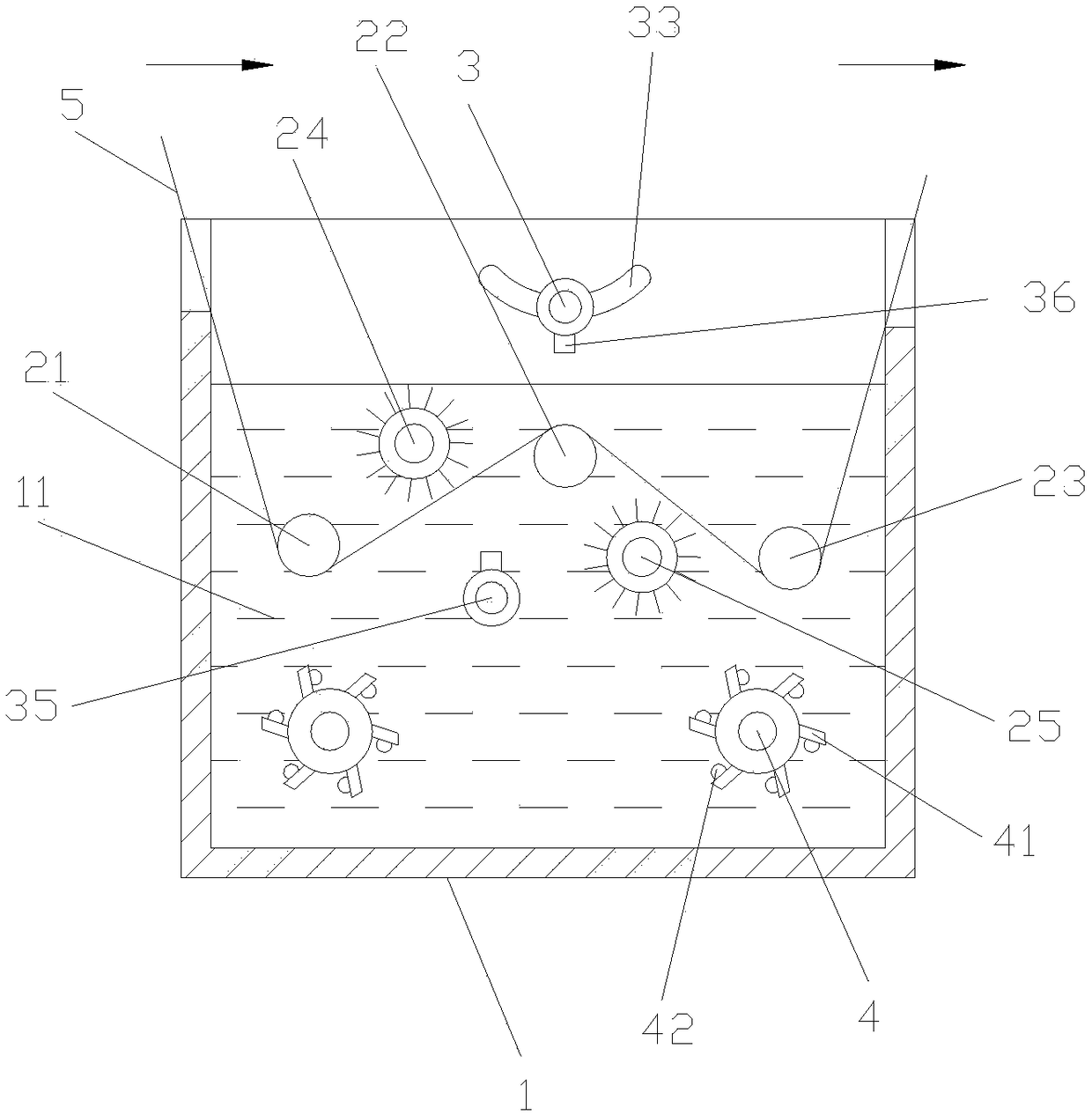

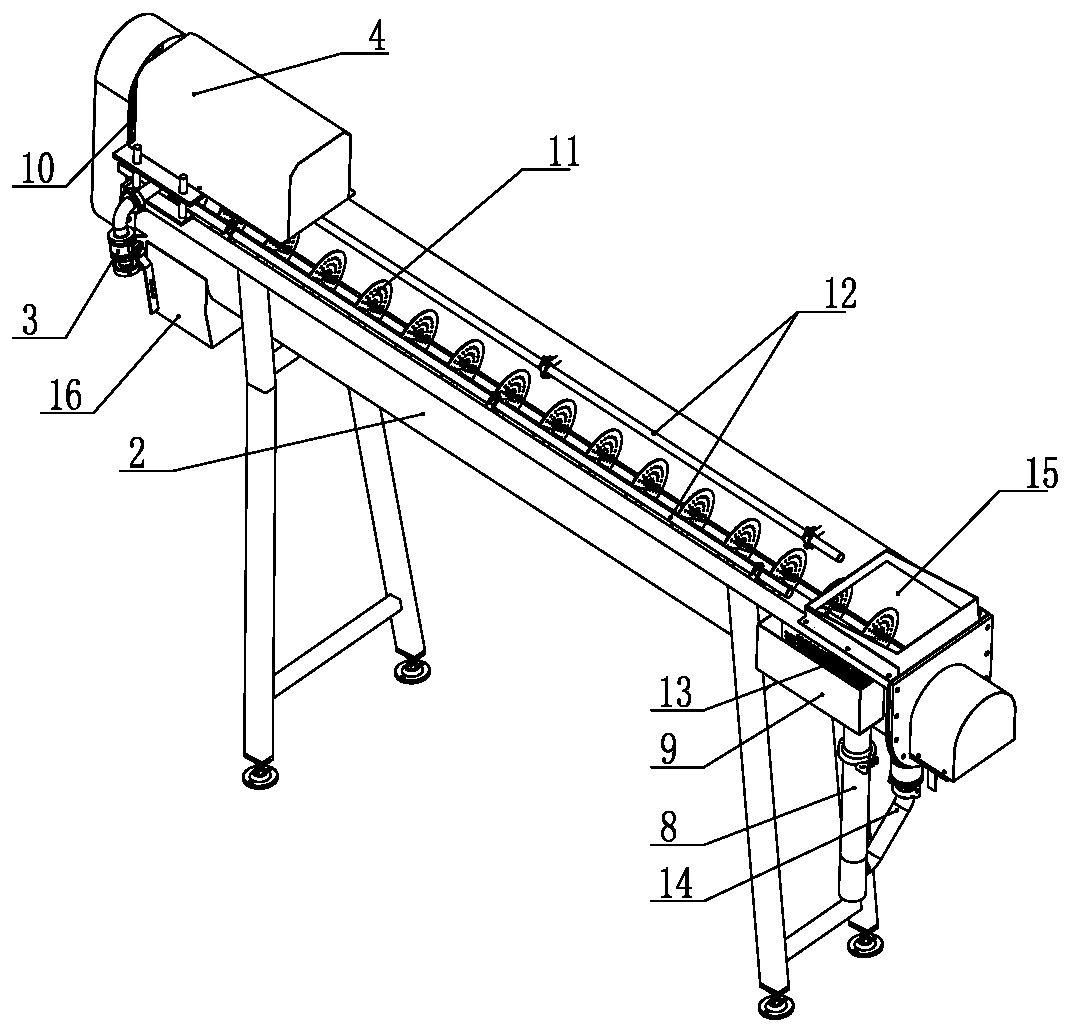

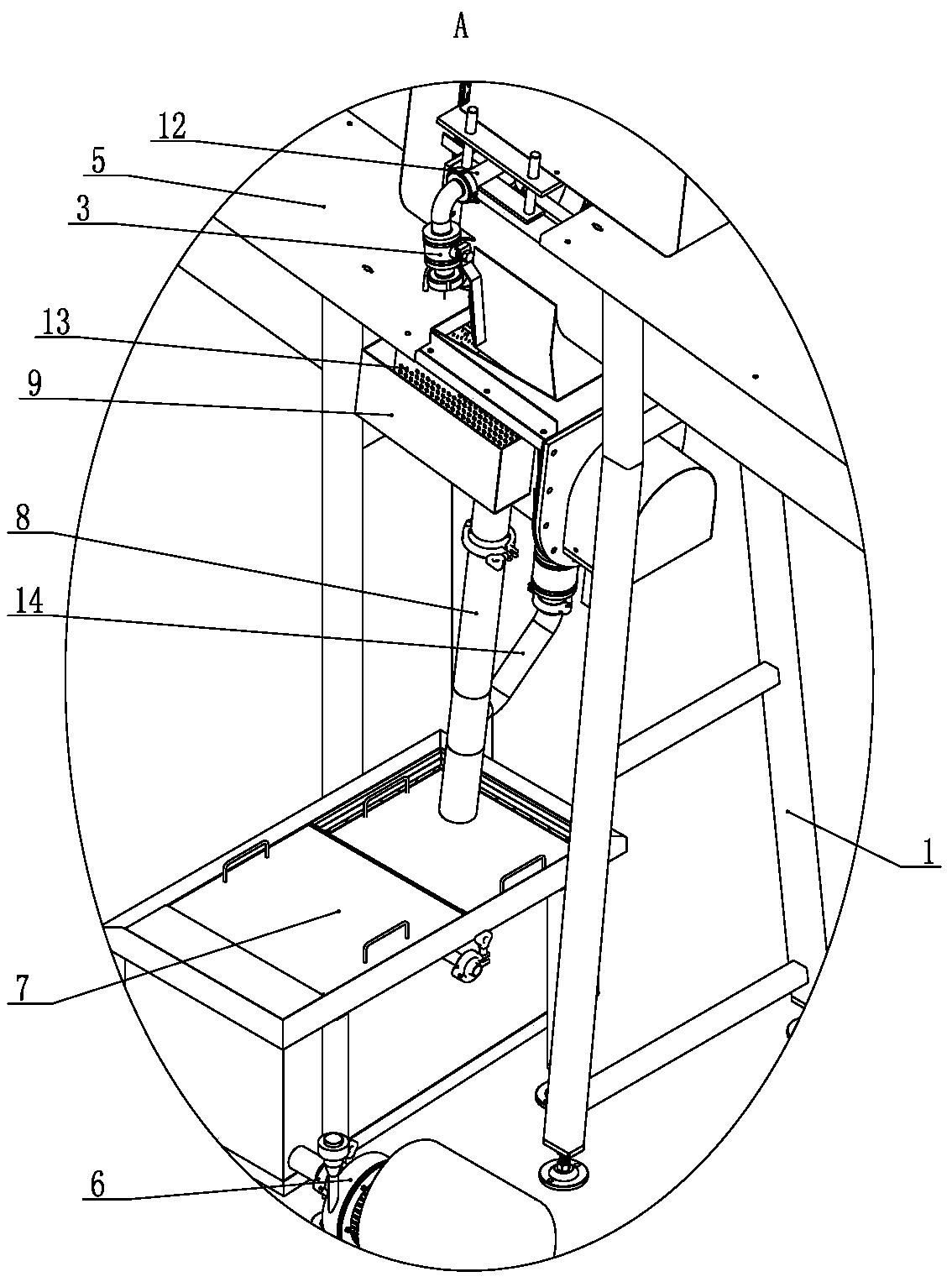

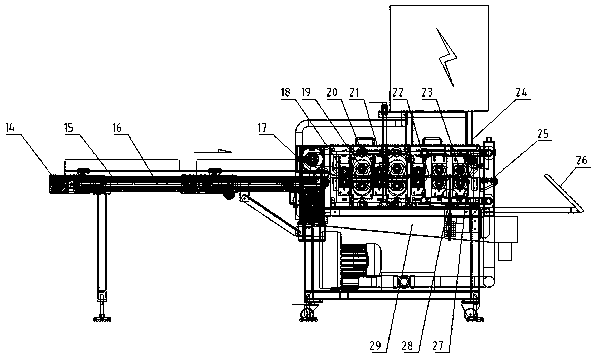

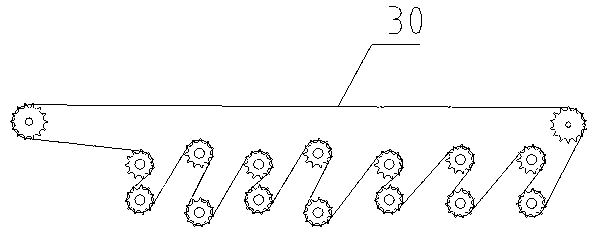

Automatic cleaning machine for mushroom sheets

InactiveCN109463777AEasy to operateThe design method is simple and applicableFood treatmentEngineeringMushroom

The invention discloses an automatic cleaning machine for mushroom sheets. The machine comprises an inlet belt conveyor; a tail portion of the inlet belt conveyor is connected with an inlet of a cleaning section; the cleaning section comprises an upper and lower support rail, a water spray pipeline and a hot air pipeline; one end of the upper and lower support rail is disposed at the tail of the inlet belt conveyor, and the other end of the upper and lower support rail is disposed at a receiving groove at the outlet of the cleaning section; the upper and lower support rail is provided with a conveying cleaning water absorption roller group; the water spraying pipeline is corresponding to the conveying cleaning water absorption roller group; a water receiving tank is arranged below the upper and lower support rail; and a hot air pipeline is disposed at the outlet of the cleaning section. The machine has the characteristics of stable mechanical performance, low manufacturing cost, cleancleaning and high production efficiency.

Owner:辽宁日富高科机械设备有限公司

Water purifier adopting rotary filtering element cleaning

InactiveCN108261828AImprove thermal stabilityChemically stableMoving filtering element filtersMotor driveSludge

The invention discloses a water purifier adopting rotary filtering element cleaning. The water purifier comprises a box, a blow-down valve and filtering elements and is characterized in that the blow-down valve is arranged at the bottom of the outer lateral wall of the box, ultrasonic vibrators are mounted at the top of the box in an equal-distance manner, a circulating device is arranged at the top end of the box in a penetrating manner, the four filtering elements are mounted inside the box through ceramic bearings, silica gel sheets with brushes wind the outer wall of the filter elements, amotor is arranged below the box, the output end of the motor is connected with cam rotary tables at the bottom of the box trough a gear, and the top ends of the cam rotary tables are connected with the bottom ends of the filtering elements. The water purifier has the advantages that the motor drives the gear and the cam rotary tables to rotate so as to allow the filtering elements mounted on thecam rotary tables to rotate at high speed to toss out impurities attached to the surfaces of the filtering elements, cams drive the silica gel sheets with the brushes to swing vertically at the same time to remove impurities and sludge on the surfaces of the filtering elements and cylinders, the rotation of the filtering elements allows the cleaning to be comprehensive, and cleaning dead angle canbe reduced.

Owner:FUZHOU PINXING TECH DEV

Feeding mixing equipment

ActiveCN106179078AThe solution is not easy to cleanMeet cleaning validation requirementsFlow mixersTransportation and packagingEngineeringMixed materials

The invention discloses feeding mixing equipment. The feeding mixing equipment comprises a material mixing device and a gas control device connected with the material mixing device. The gas control device is used for sucking materials into the material mixing device under a vacuumizing state so as to perform material transferring or mixing. The gas control device comprises a buffer cavity and a filter control part, the filter control part is accommodated in the buffer cavity and arranged between the material mixing device and the gas control device, the filter control part prevents the materials in the material mixing device from being sucked back into a vacuumizing device, and the filter control part can be opened or closed in a multi-angle manner and is convenient to clean. The feeding mixing equipment has the advantages that the problem that a traditional filter screen is difficult to clean is solved, and the cleaning and verification requirements of sterile medicine with high sanitation level are satisfied; the included angle between each material inlet of the feeding mixing equipment and the material mixing cavity is 50-85 degrees, the opening directions of the two material inlets are opposite, materials can be evenly mixed, and the mixed materials can keep the original particle form and performance to the maximum extent.

Owner:NA SHENG CLEAN TECH SUZHOU CO LTD

Beauty medical instrument cleaning and disinfecting device

InactiveCN112452844ASpray evenlyReduce cleaning dead angleCleaning using toolsCleaning using liquidsDrive shaftReduction drive

The invention discloses a beauty medical instrument cleaning and disinfecting device. The beauty medical instrument cleaning and disinfecting device comprises a cleaning box body, a brush sleeve and aconveying structure; the conveying structure comprises a sliding rod, an external thread sleeve, an internal thread sleeve and a cleaning clamping block; the sliding rod and the external thread sleeve are both rotationally connected with the cleaning box body, and the internal thread sleeve is in threaded connection with the external thread sleeve; the sliding rod is slidably connected with the internal thread sleeve, one side of the cleaning box body is fixedly connected with a control box body, the top of the control box body is fixedly connected with a motor, and the motor is connected with a driving shaft through a speed reducer; and the driving shaft is fixedly connected with an upper bevel gear, a left bevel gear and a right bevel gear are arranged on the two sides of the upper bevel gear in a meshing transmission connection mode correspondingly, the left bevel gear is fixedly connected with the sliding rod, and the right bevel gear is fixedly connected with the inner threaded sleeve. The beauty medical instrument cleaning and disinfecting device is driven to move and rotate to pass through the cleaning area, and cleaning dead corners can be effectively reduced.

Owner:合肥红蔻健康管理有限公司

Cleaning device for semiconductor preparation

InactiveCN112452877AEasy to fixReduce cleaning dead angleElectrostatic separationSemiconductor/solid-state device manufacturingElectrical conductorEngineering

The invention relates to the technical field of semiconductors, and discloses a cleaning device for semiconductor preparation. The cleaning device comprises a cleaning box, wherein fixed bases are fixedly connected to the four corners of the lower surface of the cleaning box; a door plate is arranged on the front face of the cleaning box; an operation handle is fixedly connected to the front faceof the door plate; a fixing plate is fixedly connected to the inner bottom of the cleaning box; movable rotating devices are arranged on the left side and the right side of the upper surface of the fixing plate correspondingly; and clamping devices are arranged on the inner sides of the movable rotating devices. According to the cleaning device for semiconductor preparation, a driving motor drivesa rotating disc to drive a sliding column to move inwards to move a semiconductor to be clamped and fixed, so that a better fixing effect is achieved on the semiconductor, the surface of the semiconductor can be better and uniformly cleaned in all directions, cleaning dead corners of the semiconductor are effectively reduced, the semiconductor can be better cleaned, the cleaning effect of the semiconductor is improved, and the use convenience is improved.

Owner:广州夕千科技有限公司

On-site cleaning device for muck vehicle wheel for civil construction

PendingCN114379516AImprove cleaning efficiencyEasy to cleanCleaning apparatus for vehicle exteriorsArchitectural engineeringStructural engineering

The invention relates to the technical field of civil construction, and discloses a civil construction muck wheel field cleaning device which comprises a supporting bottom plate, a spraying mechanism and a supporting mechanism. The spraying mechanism comprises a fixing base arranged on the side, away from the ground, of the supporting bottom plate, and a spraying head is arranged on the fixing base; the supporting mechanism comprises receding grooves formed in the two sides of the supporting bottom plate, fixing plates are arranged at the two ends of the receding grooves, third sliding grooves are formed in the two sides of the fixing plates and slidably connected with the ends of rotating shafts, a pressing roller is arranged in the middle of each rotating shaft, second sliding grooves are formed in the sides, close to the supporting bottom plate, of the fixing plates, and second sliding blocks are slidably connected to the second sliding grooves. The second sliding block is rotationally connected with a supporting roller matched with the pressing roller. According to the site cleaning device for the muck wheels for civil construction, the wheels are cleaned through the spray heads, so that the cleaning efficiency of the whole device is improved, and due to the fact that the wheels can rotate freely, cleaning dead corners are reduced, and the cleaning effect is improved.

Owner:安徽炬烨建设集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com