High-pressure three-dimensional water-jet oil tank cleaning device

A technology of cleaning device and water jet, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of different sizes and structures of fuel tanks, unguaranteed cleaning quality of fuel tanks, and lasting personal injury to operators. , to meet cleanliness requirements, reduce operating time and filter element consumption, and avoid occupational injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

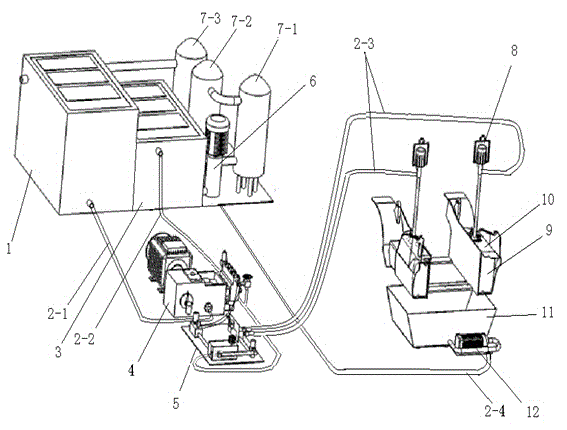

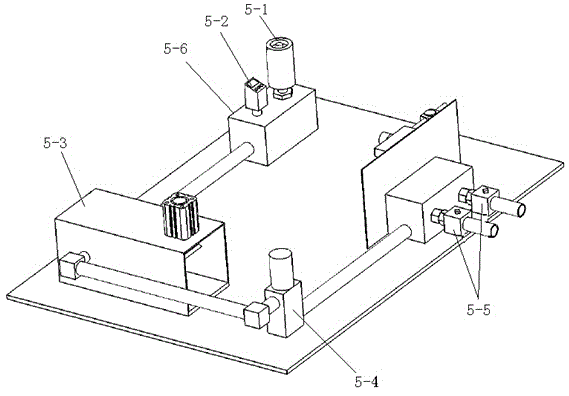

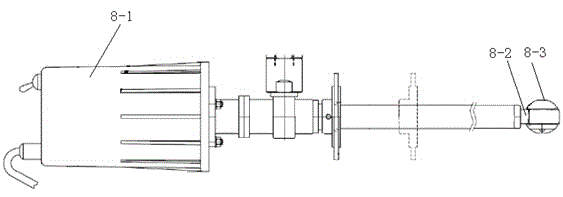

[0044] like figure 1 As shown, a high-pressure three-dimensional water jet cleaning oil tank device includes a cleaning device and a drying device. The cleaning device includes a clean water tank 1, and the outlet of the clean water tank 1 passes through the water outlet pipe 2-1 and the plunger pump 4 inlet. The outlet of the plunger pump 4 is connected to the hydraulic control circuit 5, and the outlet of the hydraulic control circuit 5 is connected to the high-pressure three-dimensional rotary nozzle 8 located inside the oil tank 9 through the high-pressure water supply pipe 2-3.

[0045] The bottom of the oil tank 9 is provided with a water receiving tank 11, the water receiving tank 11 is connected with a sewage pump 12, and the sewage pump 12 is connected with the sewage tank 3 inlet through the sewage pipe 2-4; In the device, the first filter 7-1 is connected, and the first filter 7-1 is connected with the clean water tank 1 through the second filter 7-2 and the third f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com