Energy-saving type opposite-opened four-color printing machine

A printing press, energy-saving technology, applied in the field of energy-saving split four-color printing presses, can solve the problems of tearing paper, easy sticking, waste of paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

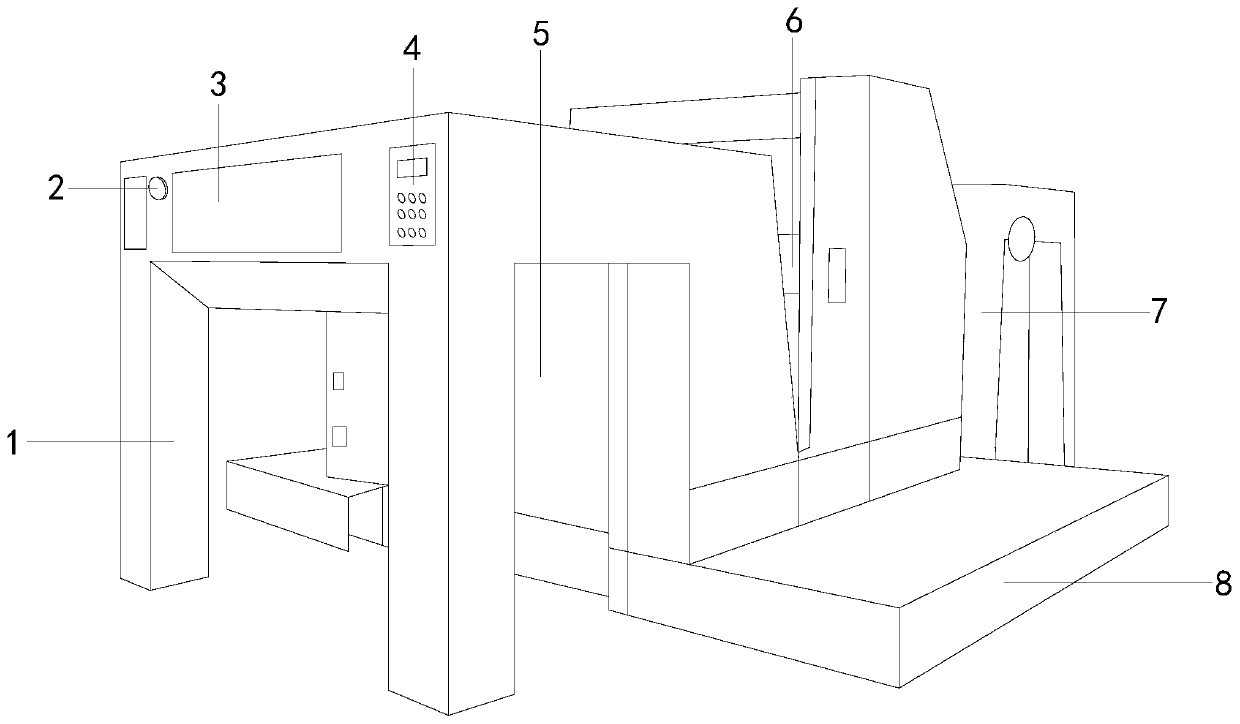

[0020] see figure 1 , the present invention provides an energy-saving folio four-color printing machine, the structure of which includes: a frame 1, a main switch 2, a display screen 3, an operation panel 4, a conveying frame 5, a printing cylinder 6, an ink cartridge 7, a base 8, The top position of the frame 1 is provided with a main switch 2 and a display screen 3, the display screen 3 is connected to the operation panel 4, the operation panel 4 is connected to the conveying frame 5, the conveying frame 5 is linked to the printing cylinder 6, and the printing cylinder 6 is connected to the ink cartridge 7 And they are all arranged in the middle of the frame 1, and the bottom of the frame 1 is provided with a base 8. On the one hand, the frame 1 is used as a load-bearing structure of the equipment, used for the installation and connection of various components on the equipment, and is also the main structure of the equipment. Play the function of supporting the structural f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com