Dry type laser cleaning device and method for nondestructive inspection liquid for aluminum alloy

A laser cleaning and non-destructive testing technology, applied in cleaning methods and utensils, chemical instruments and methods, and dust removal, etc., can solve problems such as surface damage of workpieces, and achieve the effect of less dead spots, high cleaning efficiency, and thorough cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

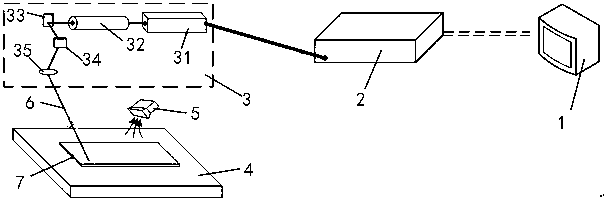

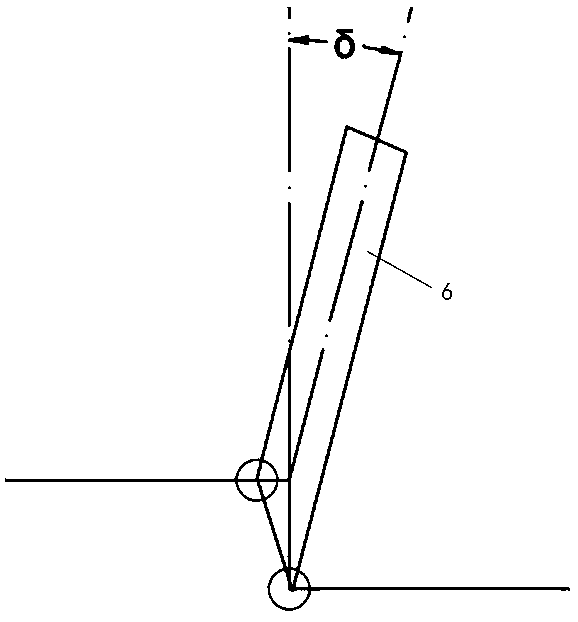

[0030] like figure 1 As shown, an aluminum alloy non-destructive testing liquid dry laser cleaning device includes a controller, the controller is connected to a laser and a dust removal device, the laser uses a nanosecond fiber pulse laser, and the laser emitted by the laser is irradiated on the surface of the workpiece through the laser cleaning head. The non-destructive testing liquid on the surface of the workpiece absorbs the laser energy and directly vaporizes and evaporates instantly to achieve the purpose of cleaning the non-destructive testing liquid on the surface of the workpiece. The laser is used to heat the flaw detection liquid on the surface of the workpiece to vaporize it insta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com