Silk rinsing device for textile production

A silk and rinsing technology, applied in the field of textile production, can solve problems such as the reduction of silk efficiency, and achieve the effects of improving stability, prolonging use time, and reducing use load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

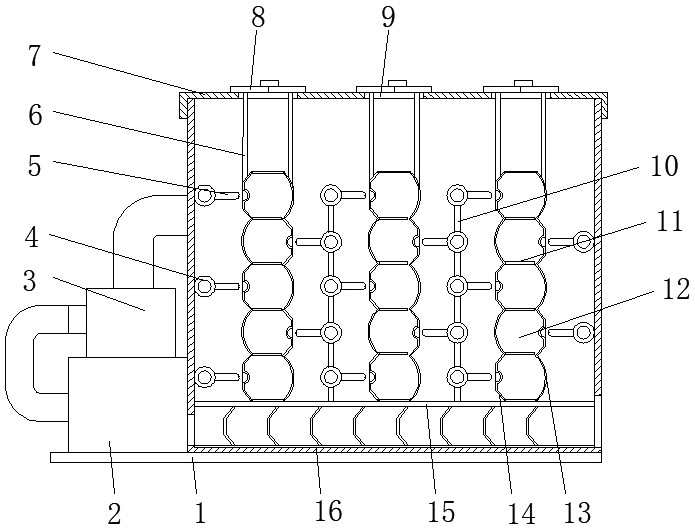

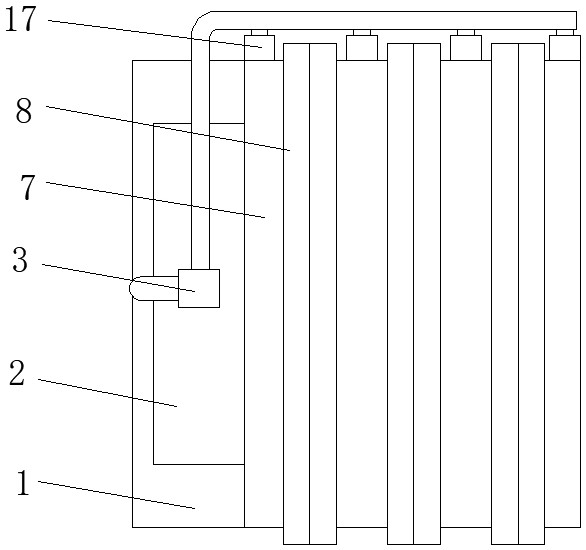

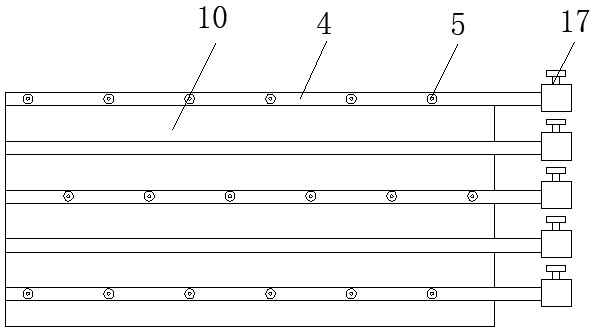

[0027] refer to Figure 1-4 , a silk rinsing device for textile production, comprising a base 1, a box 16 is fixedly installed on the top of the base 1, and a box cover 7 is fixedly installed on the top of the box 16, and a box cover 7 is fixedly installed on the top of the base 1 and the bottom of the box 16 is fixedly installed. connected to the filter 2, and the outlet end of the filter 2 is fixedly installed with a delivery pump 3, and the top of the tank cover 7 is provided with a plurality of rectangular grooves 9, and the top of the rectangular groove 9 is provided with two support plates 8, adjacent A plurality of support rods 6 are fixedly installed at the bottom of the two support plates 8, and a rinsing net box mechanism is fixedly installed between the bottoms of the support rods 6, and a plurality of blowing branch pipes 4 are fixedly installed inside the box body 16, and the spraying A plurality of flushing nozzles 5 are fixedly installed on the side of the blowi...

Embodiment 2

[0034] refer to Figure 1-5, a silk rinsing device for textile production. Compared with embodiment 1, the inner bottom end of the casing 16 is provided with a buffer mechanism 15, and the bottom end of the rinsing net box mechanism is in contact with the top of the buffer mechanism 15. The bottom of the rinsing net box mechanism is in contact with the buffer mechanism 15 during installation, and the elasticity of the buffer mechanism 15 provides protection to reduce the vibration caused by the impact of the water flow on the rinsing net box mechanism during the rinsing process, and improve the stability of the device during use.

[0035] The buffer mechanism 15 includes a plurality of rod bodies 151 and a base plate 153, and a plurality of elastic net plates 152 of C-shaped structure are fixedly installed between the plurality of rod bodies 151 and a base plate 153, and the buffer mechanism 15 is installed between the rod bodies 151 and the base plate 153 The elastic net plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com