Device for washing cuprous chloride precipitate by using anhydrous ethanol for removing chlorine from zinc sulfate solution

A technology of zinc sulfate solution and absolute ethanol, which is applied to chemical instruments and methods, cleaning methods and utensils, and cleaning hollow objects, etc., can solve the problems of flushing blind areas, reduce the range of flushing, and reduce flushing efficiency, etc., to improve flushing The effect of increasing strength, increasing the flushing range, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

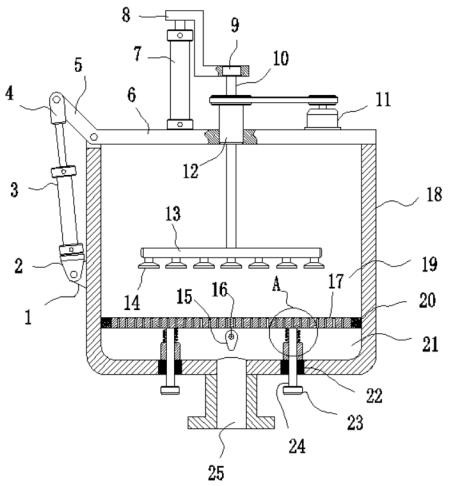

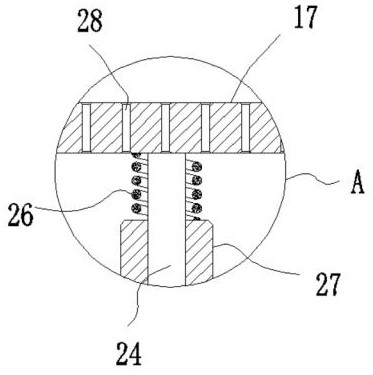

[0022] Such as Figure 1-2 Shown, a kind of zinc sulfate solution removes the device that chlorine is washed cuprous chloride precipitation with absolute ethanol, comprises a dechlorination chamber 18, and described dechlorination chamber 18 top is open and is hingedly installed with the chamber that is used to close its mouth Cover 6, the cover 6 is driven by the turning drive assembly to turn over along the hinge with the dechlorination chamber 18, and then the mouth of the dechlorination chamber 18 is opened, and the coaxial sliding card in the dechlorination chamber 18 Combined with a filter plate 17, the filter plate 17 separates the interior of the chlorine removal chamber 18 from top to bottom into a flushing chamber 19 and a liquid storage chamber 21, and the filter plate 17 is provided with a plurality of filter holes 28 in the form of through holes , the filter hole 28 communicates with the flushing chamber 19 and the liquid storage chamber 21, the filter plate 17 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com