Large diameter quartz tube cleaning method and cleaning machine

A quartz tube, large-diameter technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of unclean impurities on the surface of the quartz tube, affecting the performance of the quartz tube, affecting the cleaning quality, etc. Good cleaning effect, saving resources and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

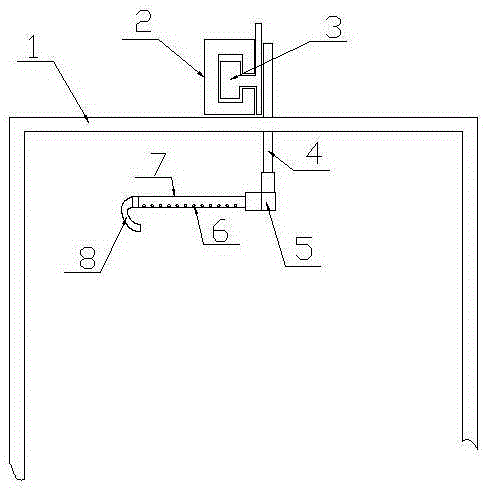

[0010] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

[0011] refer to figure 1 , a method for cleaning large-diameter quartz tubes. First, put the quartz tube into a pickling tank with a hydrofluoric acid concentration of 15% to 20%, soak for 10 to 15 minutes; then put the quartz tube into a hydrofluoric acid concentration of 7 % to 10% pickling tank, soak for 15 to 20 minutes; then put the quartz tube in the tap water tank, soak for 4 to 6 minutes; then put the quartz tube in the deionized water tank, soak for 4 to 6 minutes; The soaked quartz tube is vertically installed in the trolley, and the trolley is pushed into the cleaning machine for repeated washing. The pressure is 0.1-0.5MPa, the nozzle hole diameter of the upper nozzle is 1-5mm, and the cleaning is completed after 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com