Spraying arm assembly for dish-washing machine and dish-washing machine with spraying arm assembly

A technology of spray arm assembly and dishwasher, applied in the field of spray arm assembly and dishwasher, can solve the problems of washing dead zone and insufficient washing, and achieve the effect of increasing the washing area and improving the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

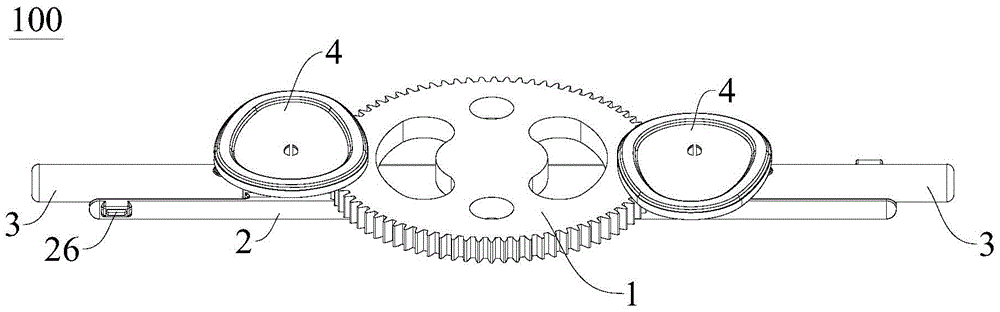

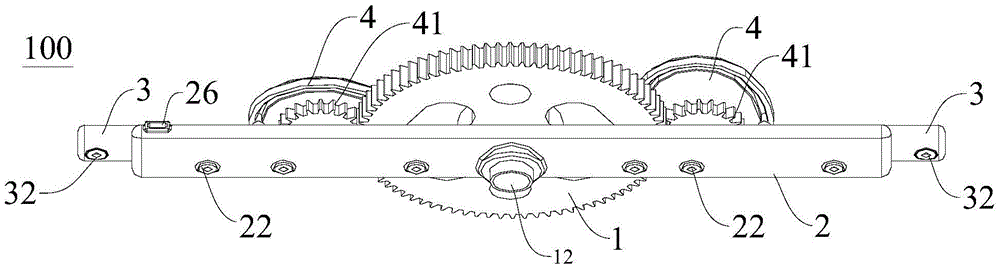

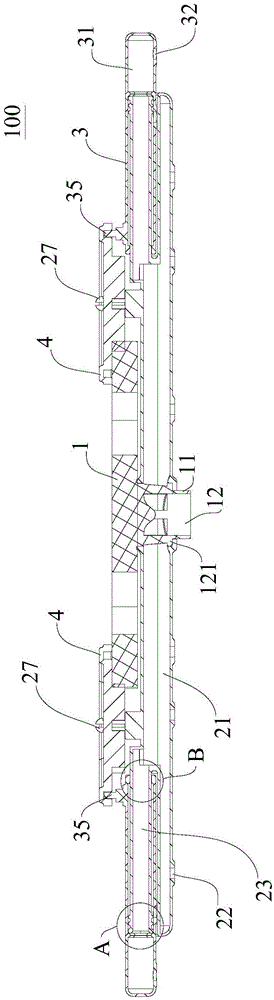

[0068] like Figure 1-Figure 3 As shown, a spray arm assembly 100 for a dishwasher 200 according to an embodiment of the present invention includes a fixed gear 1 , a main spray arm 2 , a movable spray arm 3 and a cam 4 .

[0069] The fixed gear 1 is fixed in the dishwasher 200. The main spray arm 2 is rotatably arranged on the fixed gear 1. The main spray arm 2 is defined with a first chamber 21 and the main spray arm 2 is provided with the first chamber 21. The chamber 21 communicates with the first water spray port 22 . The movable spray arm 3 is slidably arranged on the main spray arm 2 along the main spray arm 2 in the direction of approaching and away from the rotation central axis of the main spray arm 2, and the movable spray arm is defined with a chamber communicating with the first chamber 21. The second chamber 31 is provided with a second water spray port 32 on the movable spray arm. Part of the wash water entering the main spray arm 2 enters the second chamber 3...

Embodiment 2

[0077] like Figure 14 As shown, the structure of the present embodiment is substantially the same as that of the first embodiment, the difference being that the movable spray arm 3 and the cam 4 in the first embodiment pass through the guide rod 35 on the movable spray arm 4 and the guide rod 35 on the lower surface of the cam 4. The guide groove 42 is connected, and there is no guide groove 42 on the lower surface of the cam 4 in this embodiment, the main spray arm 2 and the movable spray arm 3 are connected together through the elastic member 5, wherein the same parts adopt the same reference numerals .

[0078] Specifically, refer to Figure 14 One end of the movable spray arm 3 close to the fixed gear 1 is provided with a driver 36, the relative position of the driver 36 and the movable spray arm 3 is fixed and the driver 36 is rotatably arranged on the movable spray arm 3, the driver 36 An annular groove 361 is provided on the outer peripheral surface, and the edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com