Surface treatment device for charging pile accessory production

A technology for surface treatment devices and charging piles, applied in cleaning methods and appliances, cleaning methods using liquids, cleaning methods using tools, etc., can solve problems affecting the service life of charging piles and affecting the surface treatment efficiency of supporting sheet metal, etc. Achieve the effect of improving convenience, improving filtering effect, and simple and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

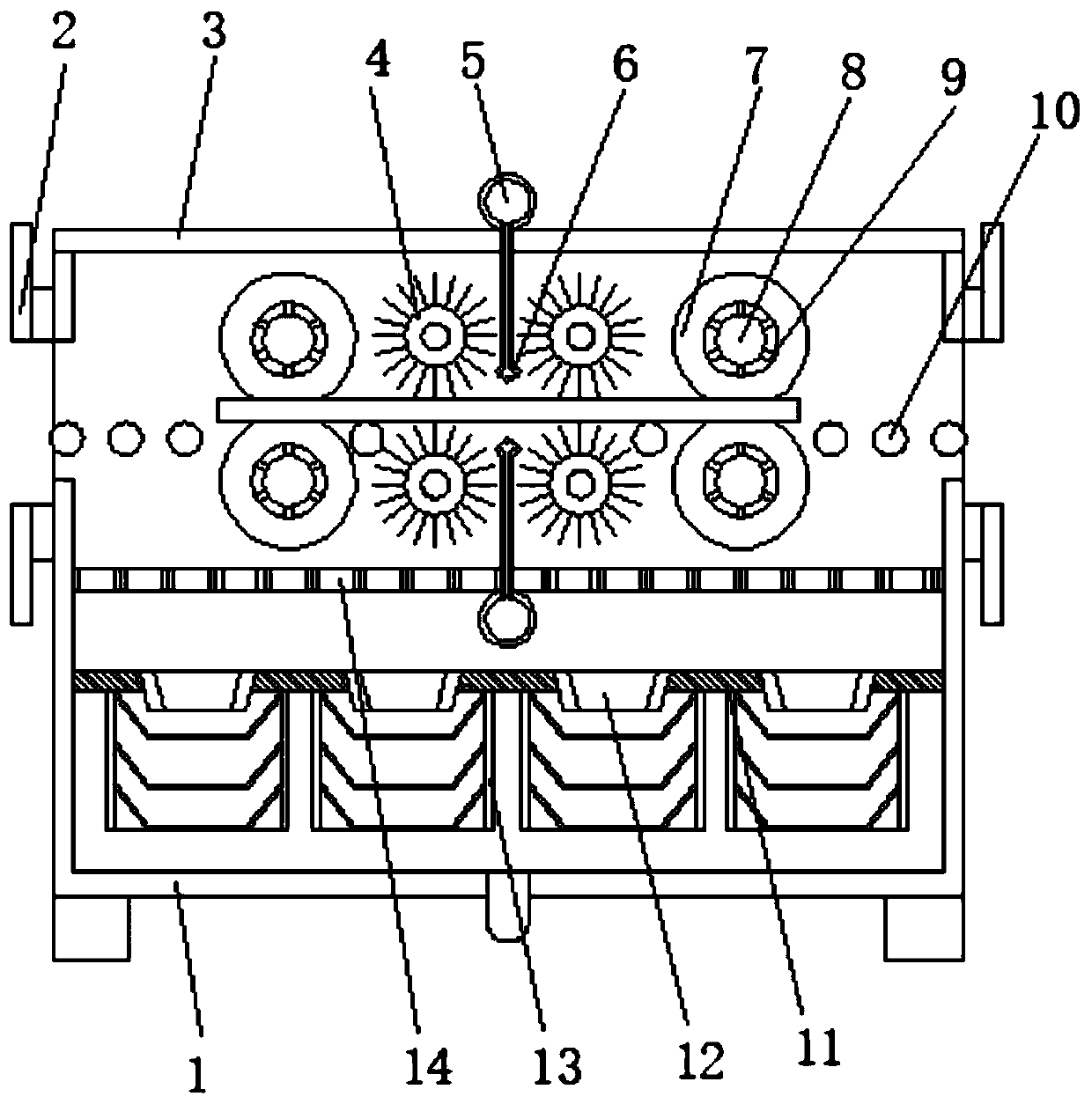

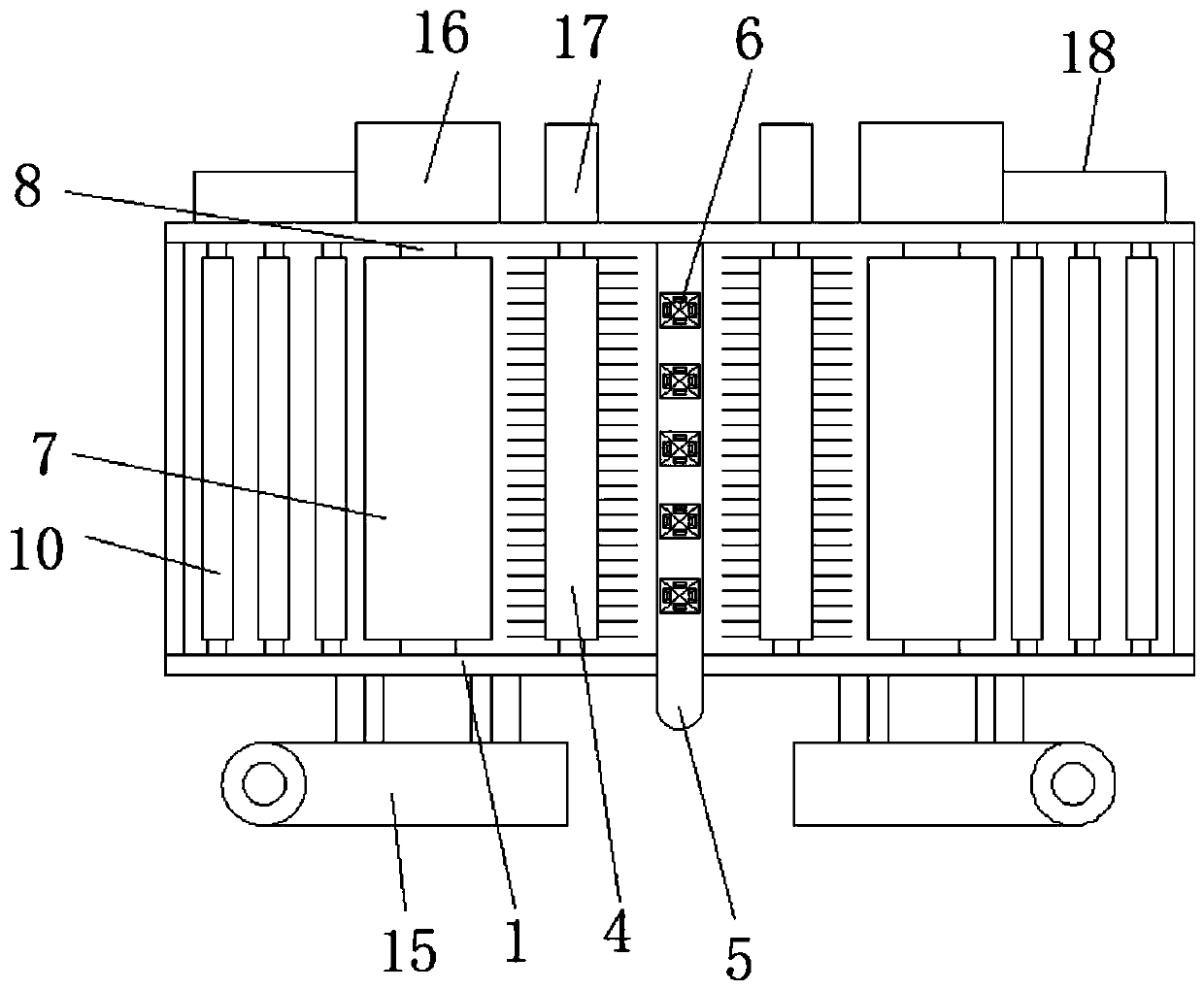

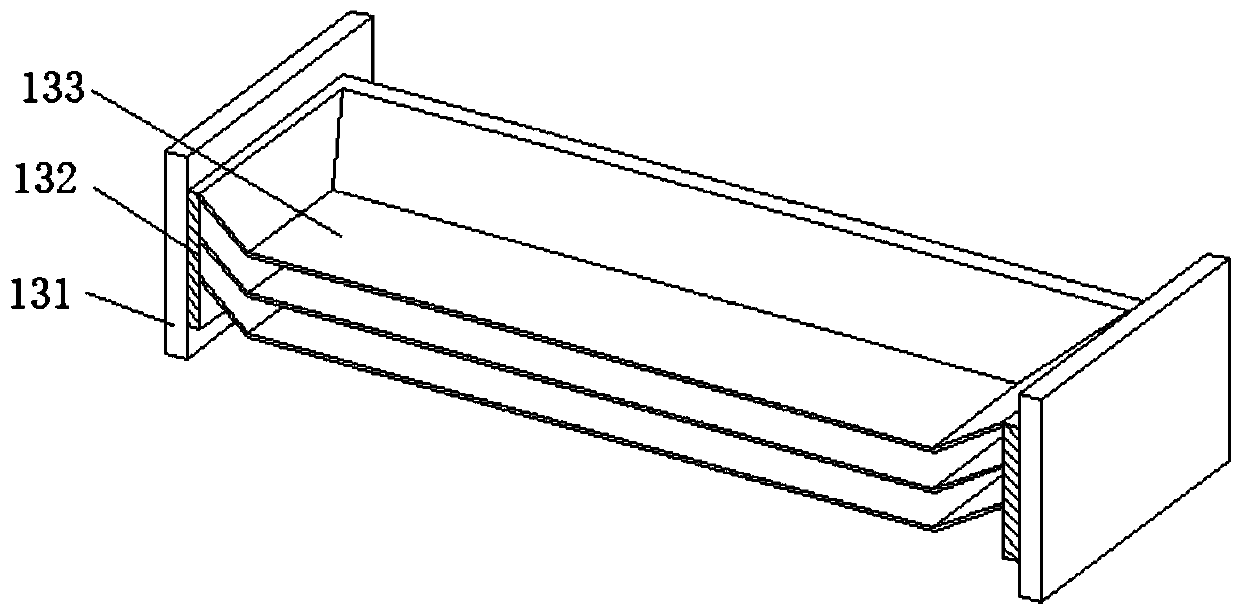

[0027] refer to Figure 1-4 , a surface treatment device for the production of charging pile accessories, including a box body 1, a box cover 3 is fixedly installed on the top of the box body 1, and a supporting mesh plate 14 is fixedly installed inside the box body 1, and a Conveying mechanism, and the bottom of the box body 1 is fixedly installed with a drain pipe, and the side of the box body 1 is fixedly installed with two sets of drive motors 16, and the output shaft of each set of drive motors 16 is connected to the inner wall of the box body 1 through bearings There is a delivery tube 8, the outer side of the delivery tube 8 is fixedly sleeved with a sponge sleeve 7, and the outer side of the delivery tube 8 is provided with a plurality of infusion holes 9, and two groups of cleaning motors 17 are fixedly installed on the side of the box body 1, and the cleaning motors A roller brush 4 is connected between the output shaft of 17 and the inner wall of the box body 1 thro...

Embodiment 2

[0035] refer to Figure 1-5 , a surface treatment device for the production of charging pile accessories, a plurality of connecting mechanisms 2 are fixedly installed at both ends of a box body 1, and the connecting mechanisms 2 are evenly distributed around the inlet and outlet of the box body 1.

[0036] The connecting mechanism 2 includes a clamping plate 22 in the shape of “几” and a connecting riser 23 welded to the side of the clamping plate 22, and a cross bolt 21 made of rubber is clamped inside the clamping plate 22.

[0037] In this embodiment, when using the device to clean the sheet metal parts, according to the oil pollution on the surface of the sheet metal parts and the cleaning situation of a single device, multiple devices can be connected in series through the connecting mechanism 2 to perform multiple cleanings on the sheet metal parts. For the second treatment, it is only necessary to clamp the cross bolt 21 between the two connecting mechanisms 22 and lock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com