Drum-shaped rotating filter net flushing system of nuclear power plant

A technology of flushing system and rotating filter screen, which is applied in the direction of filtration separation, mobile filter element filter, separation method, etc., and can solve the problems of insufficient flushing water pressure, insufficient flushing water pressure, and blockage of filter plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

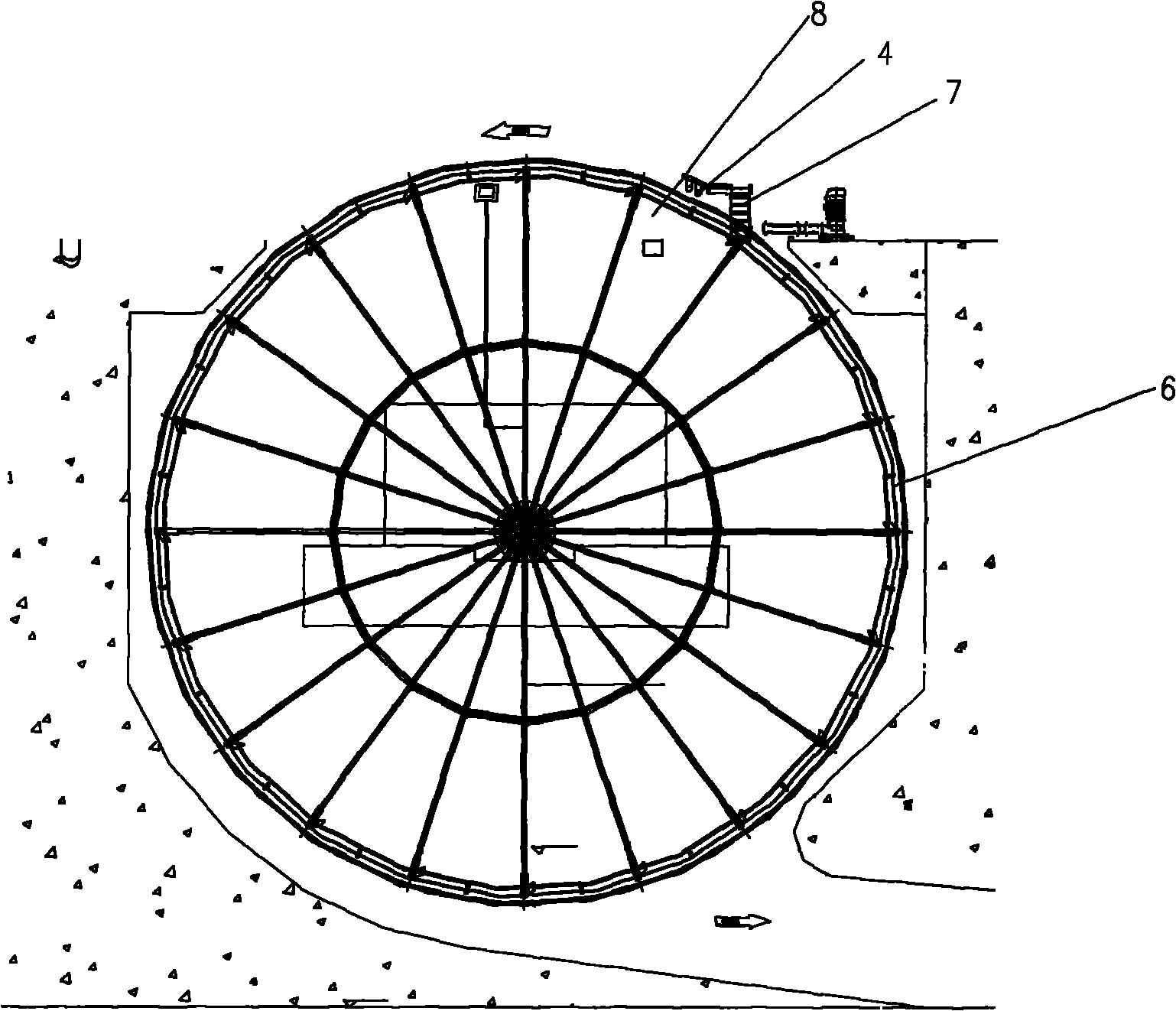

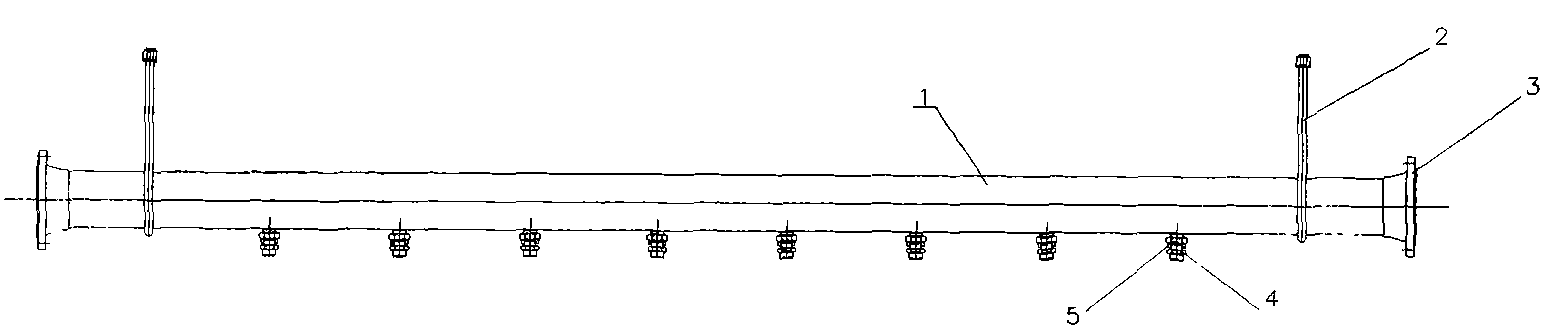

[0009] Such as Figure 1~3 As shown, the present invention is a flushing system of a nuclear power plant drum-type rotary filter screen. The top of the drum-shaped rotary filter screen 6 is a flushing system. The flushing system is fixed on the fixed bracket by two flushing pipes 1 through fastening bolts 2. 7, the length of the flushing pipe 1 is about 200mm longer than the length of the drum-type rotary screen 6, and the flushing pipe 1 is connected with the water inlet pipe through the connecting flange 3, and the flushing pipe is provided with a plurality of connecting nuts 5. Nozzle 4, the shape of the outlet of the nozzle 4 is rectangular, and directly below the flushing pipe 1 is a garbage collection device 8. When the drum-shaped rotary filter screen 6 is in normal operation, it will be on the inner surface of the filter plate of the drum-shaped rotary filter screen 6. There is a lot of garbage attached. When passing through the flushing system, the high-pressure water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com