Gravity settling chamber for monoammonium phosphate tail gas dustfall

A technology of gravity settling chamber and monoammonium phosphate, which is applied in the field of gravity settling chamber, can solve the problems of not being able to meet the comprehensive emission standards of air pollutants, difficulty in attaching exhaust dust, and accelerated airflow, so as to keep the air duct unblocked and improve the driving rate , the effect of dust content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

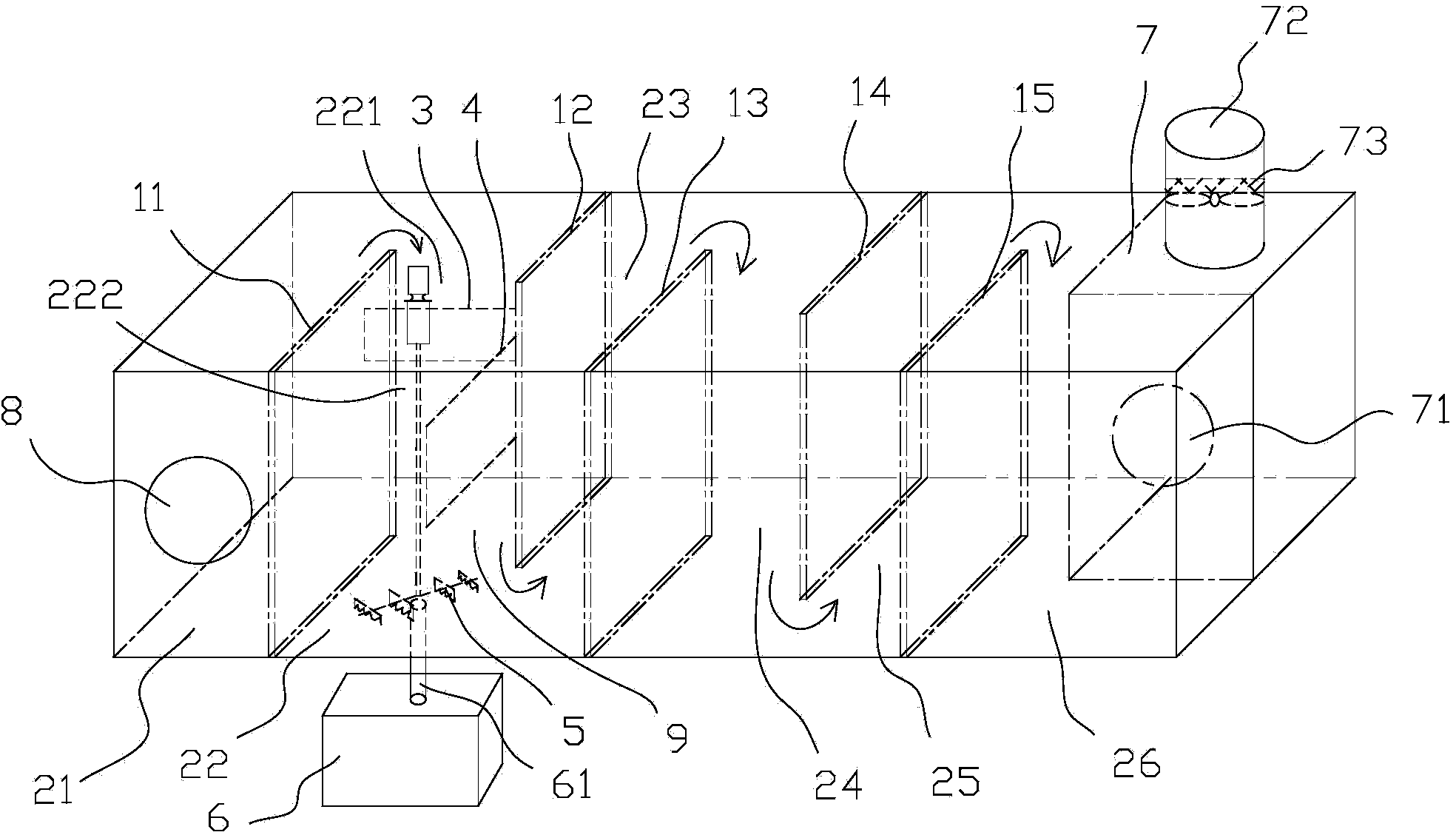

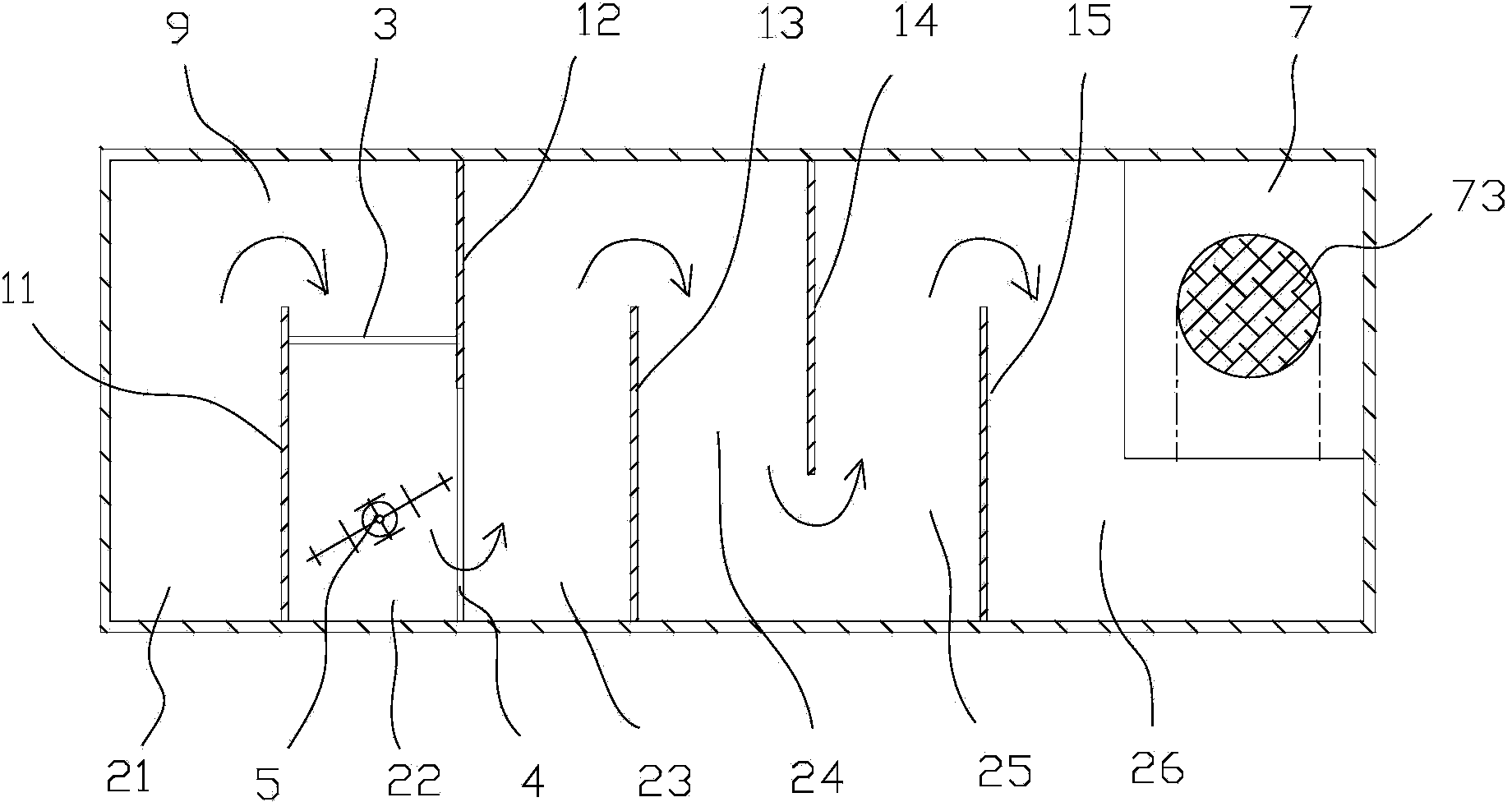

[0013] Such as figure 1 and figure 2 As shown, the settling chamber is provided with five retaining walls 11, 12, 13, 14, and 15 arranged vertically and staggeredly, which divides the settling chamber into six air chambers 21, 22, 23, 24, 25, and 26. One side of the retaining wall There is an air flow channel 9 leading to the adjacent air chamber between the inner wall of the settling chamber, so that the tail gas passes through each air chamber in a zigzag shape.

[0014] The air flow channel between the second retaining wall 12 and the inner wall of the settling chamber is provided with a longitudinal partition 4, and the longitudinal partition 4 divides the air flow channel 9 into upper and lower parts. Preferably, the area of the longitudinal partition 4 is 1 / 5 to 1 / 4 of the cross-sectional area of the airflow passage 9, and the area ratio of the upper and lower parts of the airflow passage on the longitudinal partition is 1 / 3 to 1 / 2.

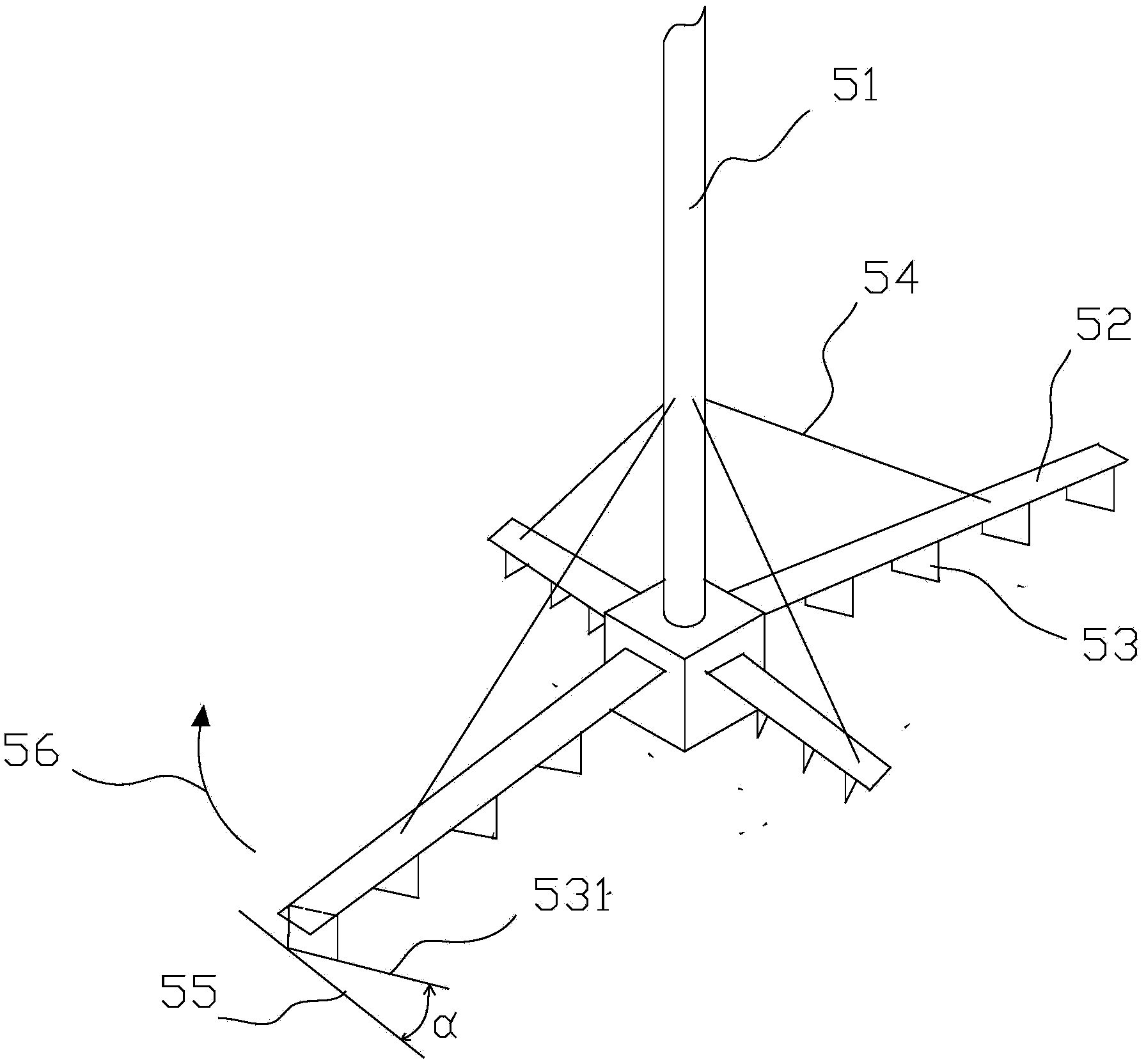

[0015] The bottom of the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com