Rapid heating extraction method of extraction tank

An extraction tank and extraction technology, used in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of production stagnation, reduced production of compound fertilizer systems, and long heating time of extraction tanks, etc. The concentration time is fast and the effect of saving heating and concentration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

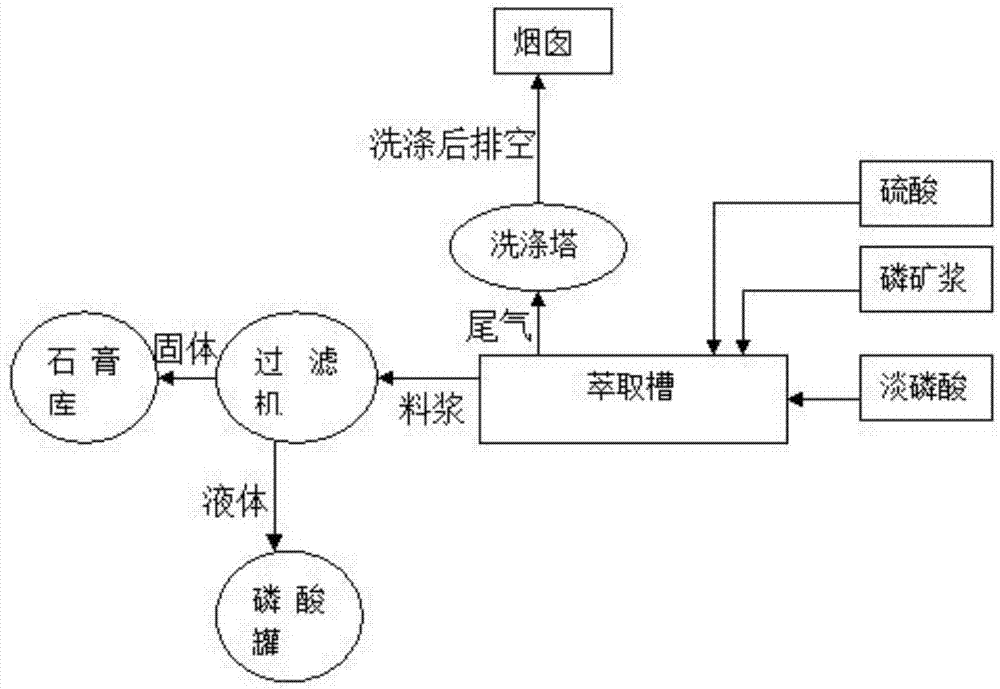

[0017] Such as figure 1 , the extraction tank shown in , after cleaning the extraction tank, add 140 cubic meters of light phosphoric acid with a concentration of 1 to 19% to the 1.5m of the extraction tank, turn on the stirring in each area of the extraction tank and the exhaust fan, and keep the extraction tank slightly negative Pressure 300pa, at 3m 3 / h speed and at 5m 3 Add 93% sulfuric acid and 29% phosphorous pulp to the extraction tank at a speed of 1 / h to raise the temperature and increase the concentration. The volume ratio of sulfuric acid and phosphorous pulp is 1:1.6. 3 Concentration value, get SO 3 The concentration is 0.020g / ml, increase the adding speed of sulfuric acid to 5m 3 / h, SO 3 When the concentration is 0.028g / ml, the adding speed of callback sulfuric acid is 3m 3 / h; At this time, the specific gravity of the extracted phosphoric acid is 1.20g / cm 3 , add 80 cubic meters of 1-19% light phosphoric acid, so that the specific gravity of the extract...

Embodiment 2

[0020] After the extraction tank is cleaned up, add 140 cubic meters of light phosphoric acid with a concentration of 1 to 19% to the 1.5m of the extraction tank, turn on the stirring and exhaust fans in each area of the extraction tank, and keep a slight negative pressure of 500pa in the extraction tank. 3 / h speed and at 5m 3 Add 93% sulfuric acid and 29% phosphorous pulp to the extraction tank at a speed of 1 / h to raise the temperature and increase concentration. The volume ratio of sulfuric acid and phosphorous pulp is 1:1.5. 3 Concentration value, get SO 3 The concentration is 0.036g / ml; the specific gravity of the extracted phosphoric acid is 1.28g / cm 3 , adding 50 cubic meters of sewage from the cleaning and filtration system, so that the specific gravity of the extracted phosphoric acid is 1.23g / cm 3 , the extraction bath is located at 2.9m.

[0021] When the extraction temperature reaches 60 degrees, adjust the negative pressure of the exhaust fan to 1500pa, with...

Embodiment 3

[0023] Such as figure 1 , the extraction tank shown in , after cleaning the extraction tank, add 140 cubic meters of light phosphoric acid with a concentration of 1 to 19% to the 1.5m of the extraction tank, turn on the stirring in each area of the extraction tank and the exhaust fan, and keep the extraction tank slightly negative Pressure 400pa, at 3m 3 / h speed and at 5m 3 Add 93% sulfuric acid and 29% phosphorous pulp to the extraction tank at a speed of 1 / h to raise the temperature and increase concentration. The volume ratio of sulfuric acid and phosphorous pulp is 1:1.5. 3 Concentration value, get SO 3 The concentration is 0.021g / ml, increase the adding speed of sulfuric acid to 5m 3 / h,SO 3 When the concentration is 0.029g / ml, the adding speed of callback sulfuric acid is 3m 3 / h; At this time, the specific gravity of the extracted phosphoric acid is 1.20g / cm 3 , add 80 cubic meters of 1-19% light phosphoric acid, so that the specific gravity of the extracted ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com