Simple tubular filter

A pipeline dredger and the same technology, applied in the field of pipeline dredges, can solve problems such as long time for shutting down production to dredge pipelines, threatening the physical and mental health of employees, and affecting the continuous and stable production, so as to reduce the control of technical indicators, improve the reuse rate, and improve Effects on Yield and Equipment Availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

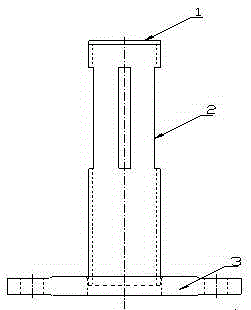

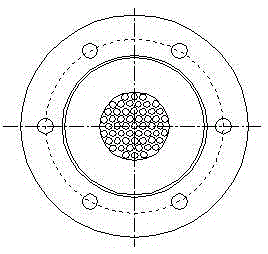

[0016] Such as figure 1 As shown, a pipe dredger includes a stay rope (1), a suspension ring (2), a cylinder body (3), and a bottom plate (4). The stay rope (1) is connected to the suspension ring (2) through a knot, the suspension ring (2) is fixedly connected to the cylinder body (3), and the cylinder body (3) is fixedly connected to the bottom plate (4).

[0017] The diameter of the cylinder (1) and the bottom plate (2) is selected according to the diameter of the pipeline on site. The diameter is slightly smaller than the inner diameter of the pipeline, and the material is not limited. The height of the cylinder is selected according to the resistance of the blocked pipeline.

[0018] The length of the pull rope is selected according to the length of the blocked pipe. The length of the pull rope must be greater than the length of the pipe. The same dredge can be e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com