Overlapped natural gas liquified system in mixed refrigerant cycling expansion machine

A mixed refrigerant and natural gas technology, applied in refrigeration and liquefaction, refrigerators, liquefaction, etc., can solve the problems of complex system control and expensive equipment costs, and achieve the effects of streamlining the liquefaction process, reducing investment costs, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

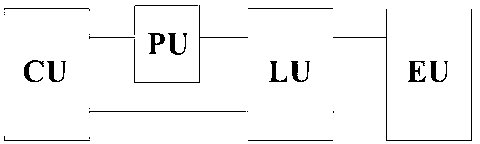

[0027] Such as figure 1 As shown, a cascade natural gas liquefaction system in a mixed refrigerant cycle expander, which includes a compressor module CU, a pre-cooling module PU, a condensation module LU and a liquefaction module EU; the high-pressure outlet pipe of the compressor module CU is connected to the pre-cooling module The high-pressure inlet pipe of the PU; the low-pressure inlet pipe of the compressor module CU is connected to the low-pressure outlet pipe of the condensing module LU; the high-pressure outlet pipe of the pre-cooling module PU is connected to the high-pressure inlet pipe of the condensing module LU; the high-pressure outlet pipe of the condensing module LU is connected to the liquefaction module The high-pressure inlet pipe of EU; the low-pressure inlet pipe of the condensing module LU is connected to the low-pressure outlet pipe of the liquefaction module EU.

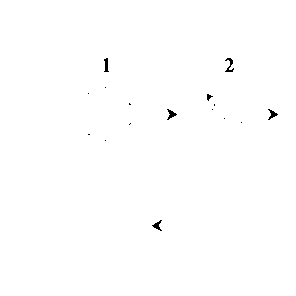

[0028] Such as figure 2 As shown, the compressor module CU includes a main compressor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com