Complexing method of boron trifluoride methylcarbonate complex

A technology of dimethyl carbonate and boron trifluoride, which is applied in the field of complex compound preparation, can solve the problems affecting the product quality of pharmaceutical companies, the difficulty of selecting materials for production equipment, and the entry of metal ions, so as to overcome equipment corrosion and achieve excellent product quality , the effect of simplifying the production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

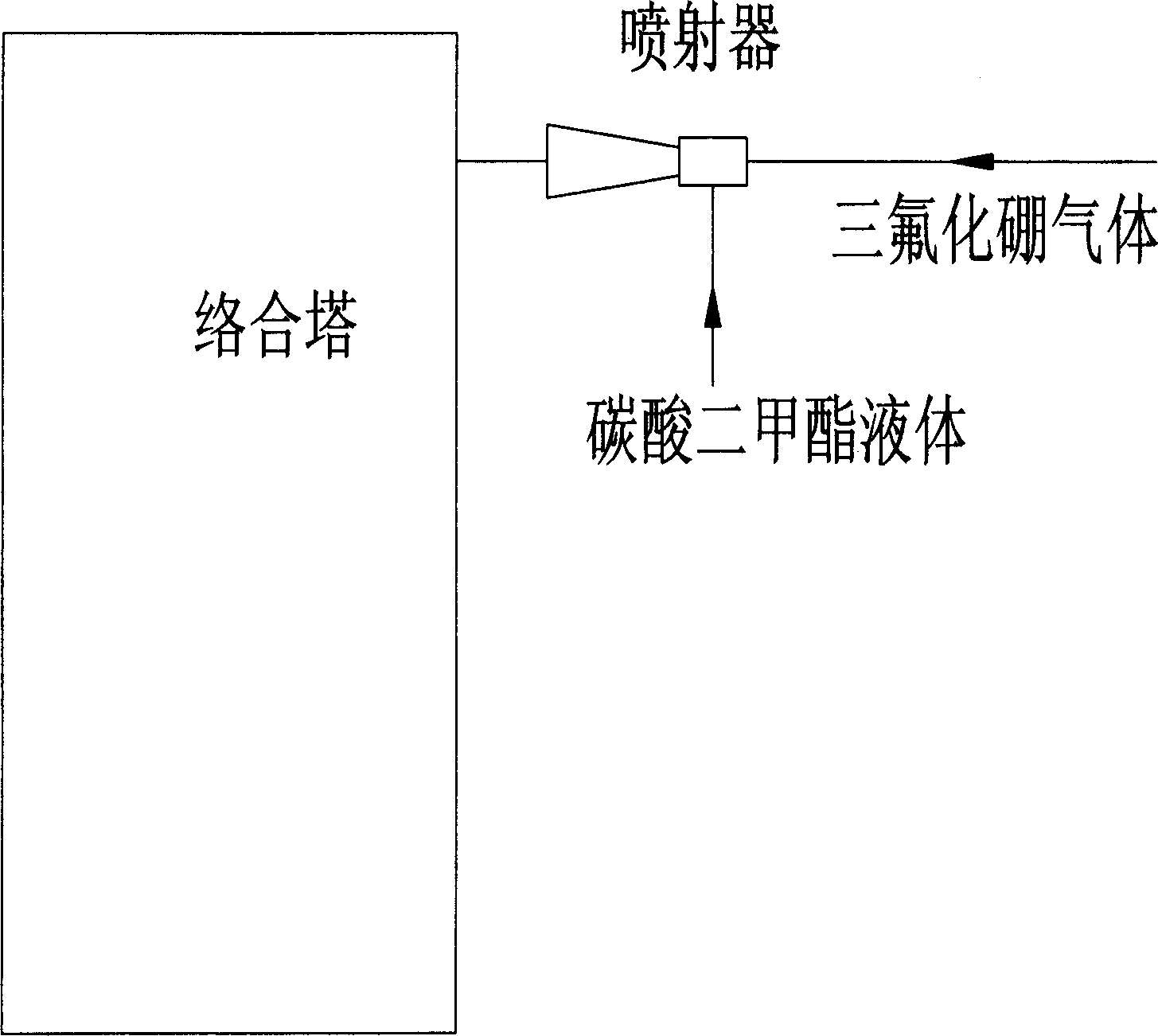

[0018] Process plan one:

[0019] Boron trifluoride gas and dimethyl carbonate mixed spray method:

[0020] combine figure 1 , boron trifluoride gas with a certain pressure enters the jet gas injector, and the power of boron trifluoride gas is used to bring liquid dimethyl carbonate into the jet. The dimethyl carbonate is atomized in the mixer, and the atomized dimethyl carbonate is sprayed into the complexing tower together with boron trifluoride gas, and a solid complex is directly formed in the complexing tower. In this process, the mass ratio of boron trifluoride gas to dimethyl carbonate is 1:0.5—1:1.5; during the complexation process, the complexation tower should be cooled to take away the heat of reaction generated by complexation, and control the temperature of the complexation tower Below 90°C; complexation control pressure 0.03-0.11Mpa (absolute pressure). Glacial acetic acid can be added to the dimethyl carbonate complexing agent, and the mass ratio of dimethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com