Desulfurization liquid cooperated chlorine dioxide gas-phase oxidation denitration integrated flue gas purification device and process

A flue gas purification and desulfurization liquid technology, applied in inorganic chemistry, gas treatment, alkali metal compounds, etc., can solve the problems of loss of denitration effect of desulfurization liquid, high cost of recovered resources, and increase of alkali consumption for denitrification, etc., so as to improve the overall desulfurization Denitrification and dust removal efficiency, reduction of denitration cost and waste liquid discharge, and effect of saving oxidant consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

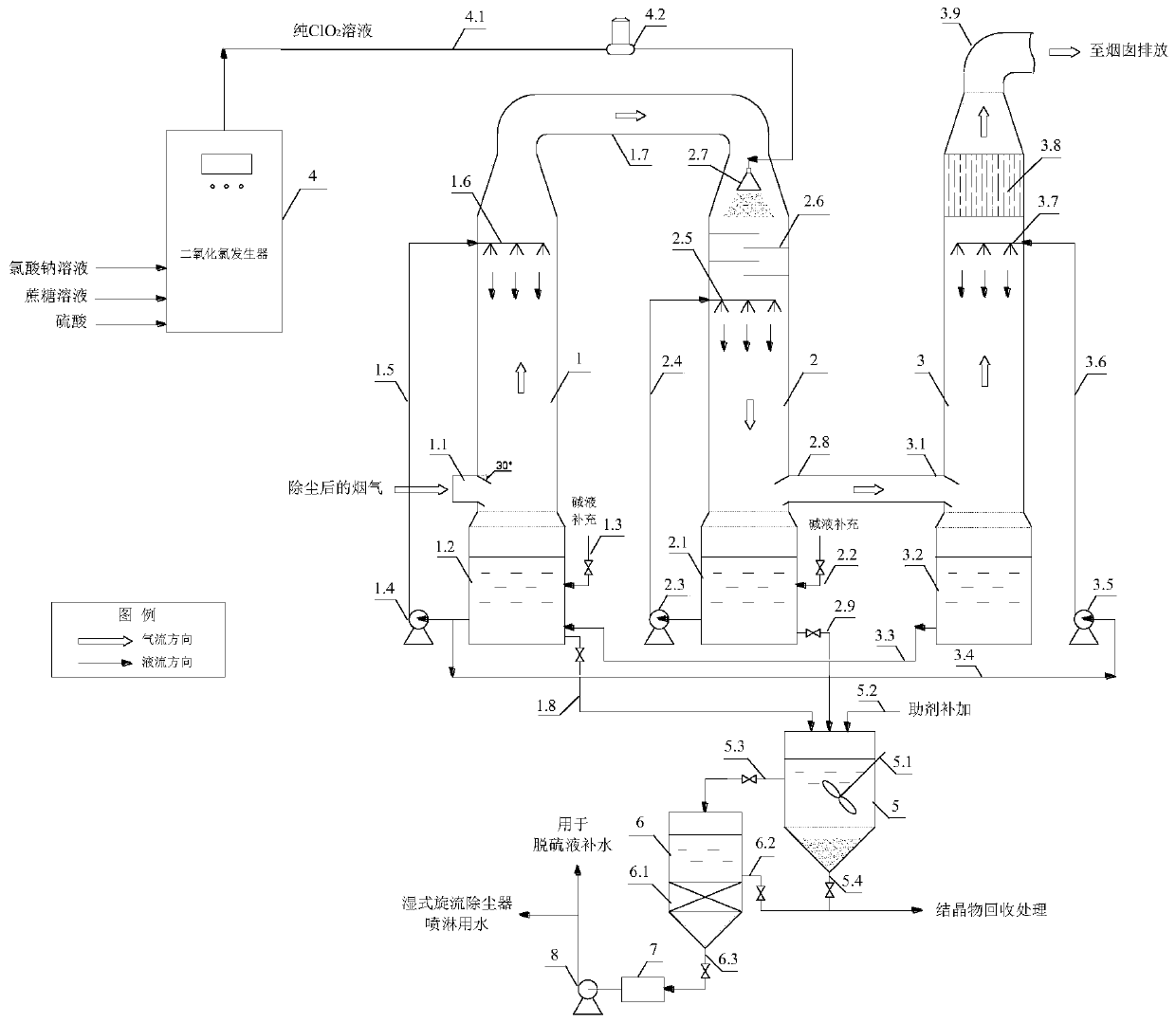

[0056] Using the present invention figure 1 The process shown is to treat the flue gas of a 30t / h heat medium oil chain grate coal-fired boiler. Flue gas flow rate is 64400m 3 / h, particulate matter is 1963~1989mg / m 3 , SO 2 896~913mg / m 3 , NO x 290~320mg / m 3 (NO accounts for about 95%); before the flue gas enters the desulfurization tower, the multi-tube dust collector and the wet cyclone dust collector are used for dust removal.

[0057] The desulfurization agent uses NaOH, the concentration is 0.5mol / L, the pH is maintained at 6-8 during the operation, and the circulation volume of desulfurization liquid is 80m 3 / h (liquid-gas ratio: 1.2L / m 3 ); the denitration agent uses NaOH, the concentration is 0.2mol / L, the pH is maintained at 6-8 during the operation, and the denitrification liquid circulation volume is 50m 3 / h (liquid-gas ratio: 0.8L / m 3 ), ClO 2 The supply rate is 22kg / h (ClO 2 / NO molar ratio: 0.52); the spray liquid of the secondary purification tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com