Method of manufacturing compound single crystal and apparatus for manufacturing it

A single crystal manufacturing device and manufacturing method technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of growth rate reduction, uneven crystal nuclei, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

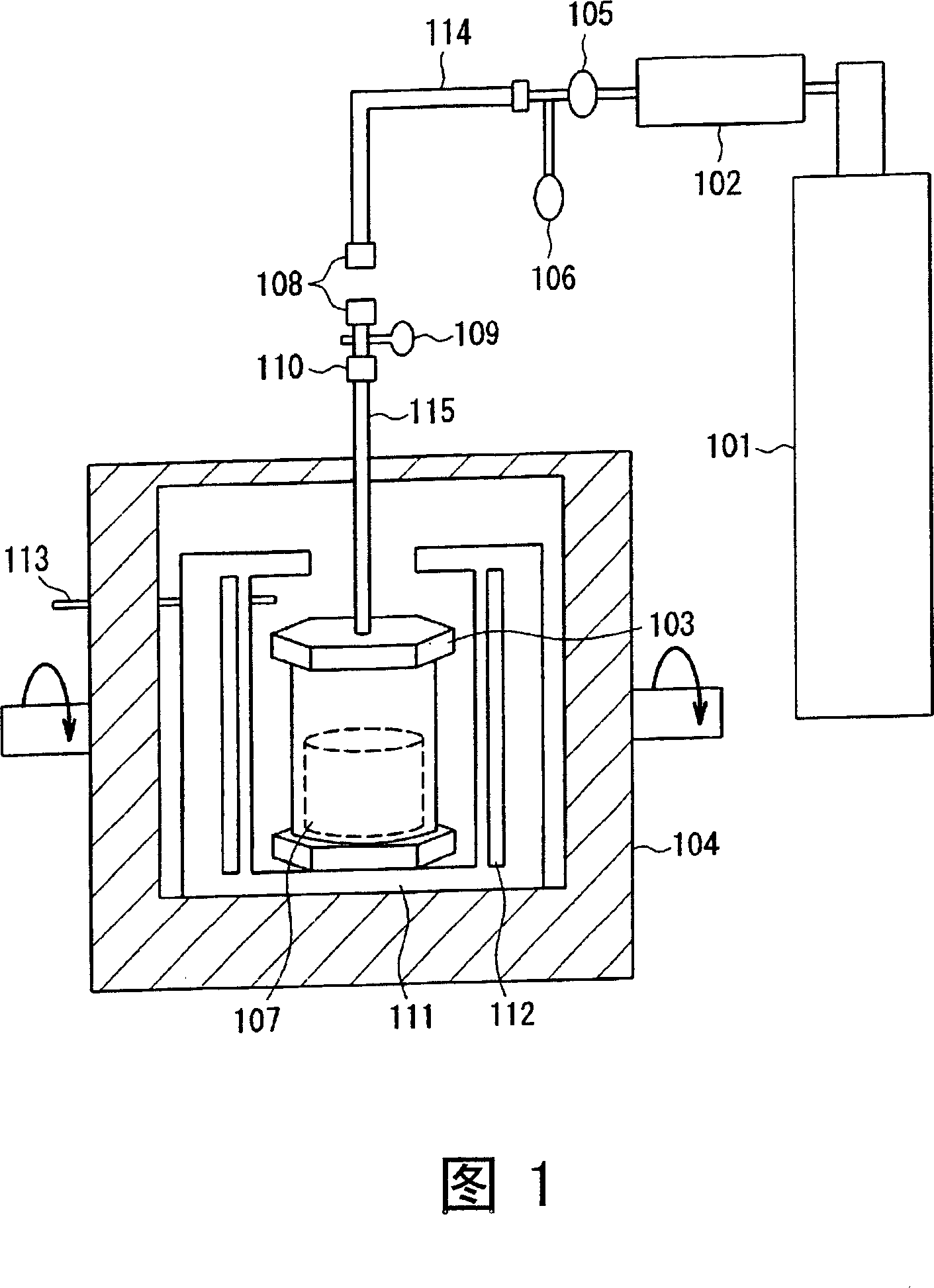

[0112] This aspect is an example in which the airtight pressure-resistant and heat-resistant container can be disconnected from the connecting pipe, and the above-mentioned airtight pressure-resistant and heat-resistant container can also be shaken by the shaking heating device. Hereinafter, an example of the manufacturing apparatus of this aspect and an example of the manufacturing method using it are demonstrated.

[0113] The above-mentioned manufacturing apparatus has a raw material gas supply device for supplying raw material gas, a pressure regulator for adjusting the pressure of the culture atmosphere, a sealed pressure-resistant and heat-resistant container for crystal growth, a heating device, and a shaking heating device as a whole. device. As the source gas, a gas containing nitrogen or ammonia can be used. As the airtight pressure-resistant and heat-resistant container, for example, SUS materials such as SUS316, Inconel, Hastelloy, or Inkoroy can be used. Certain...

Embodiment approach 2

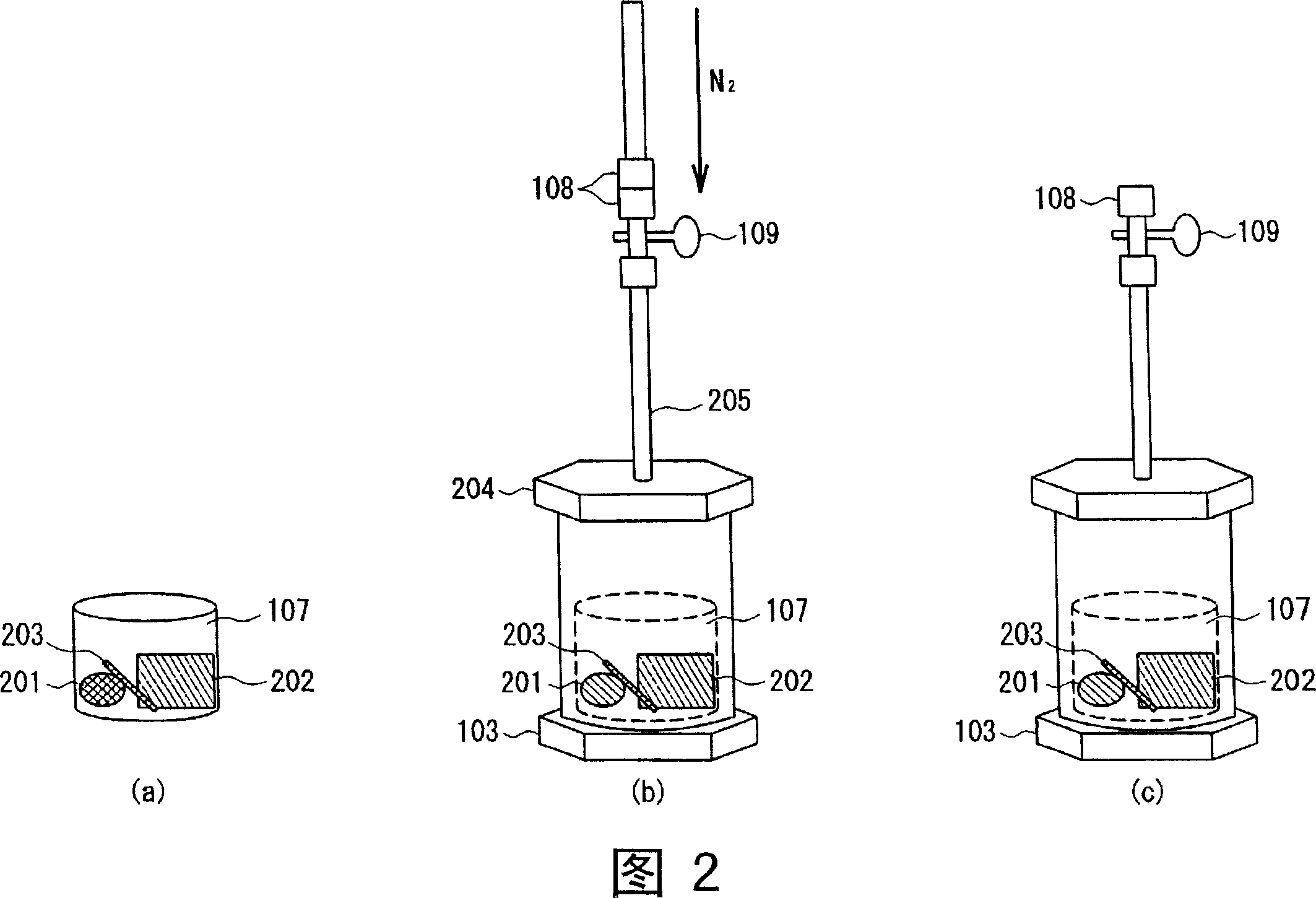

[0138] This aspect is an example in which the airtight pressure-resistant and heat-resistant container can be disconnected from the connecting pipe, and only the above-mentioned airtight pressure-resistant and heat-resistant container can be shaken. Hereinafter, an example of the manufacturing apparatus of this aspect and an example of the manufacturing method using it are demonstrated.

[0139] The above-mentioned manufacturing apparatus has a raw material gas supply device for supplying raw material gas, a pressure regulator for adjusting the pressure of the culture atmosphere, a sealed pressure-resistant and heat-resistant container for crystal culture, a heating device (cultivation furnace), and a shaker for shaking. The rotating mechanism of the airtight pressure-resistant and heat-resistant container. The above-mentioned airtight pressure-resistant and heat-resistant container is rotated by the above-mentioned rotating mechanism. When the crucible is inserted and fixed ...

Embodiment approach 3

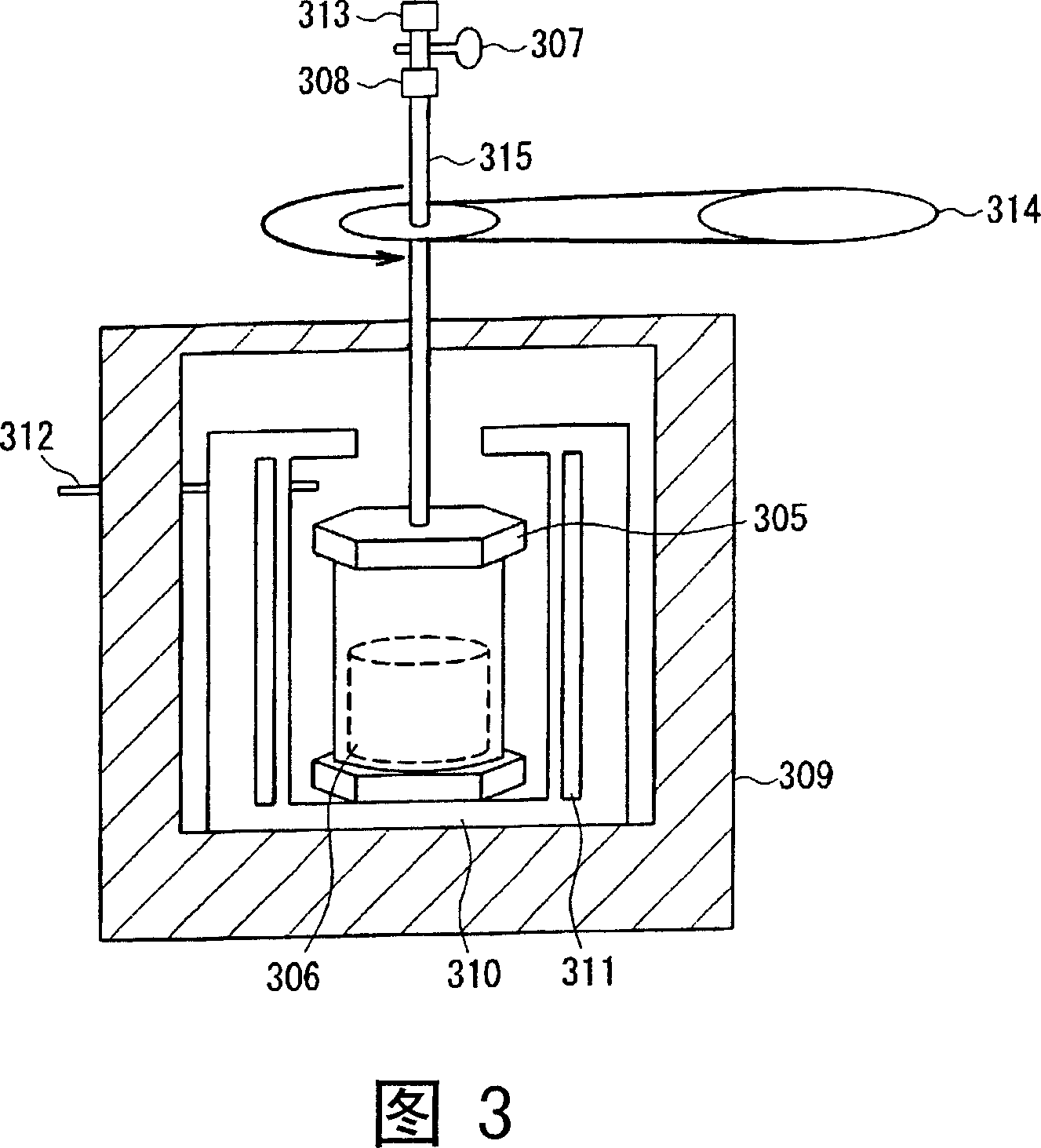

[0146] This embodiment is an example in which a raw material gas supply device is connected to an airtight pressure-resistant and heat-resistant container using a flexible tube, and the container is shaken without disconnecting the raw material gas supply device and the container. Hereinafter, an example of the manufacturing apparatus of this aspect and an example of the manufacturing method using it are demonstrated.

[0147] The above production apparatus has a raw material gas supply device for supplying raw material gas, a pressure regulator for adjusting the pressure of the culture atmosphere, a sealed pressure-resistant and heat-resistant container for crystal growth, a flexible tube, and a heating device (cultivation furnace). A shaking device integrated with a shaking heating device (cultivation furnace). Since the above-mentioned raw material gas supply device and the above-mentioned airtight pressure-resistant and heat-resistant container are connected by a flexible ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com