Method for preparing MOF-5

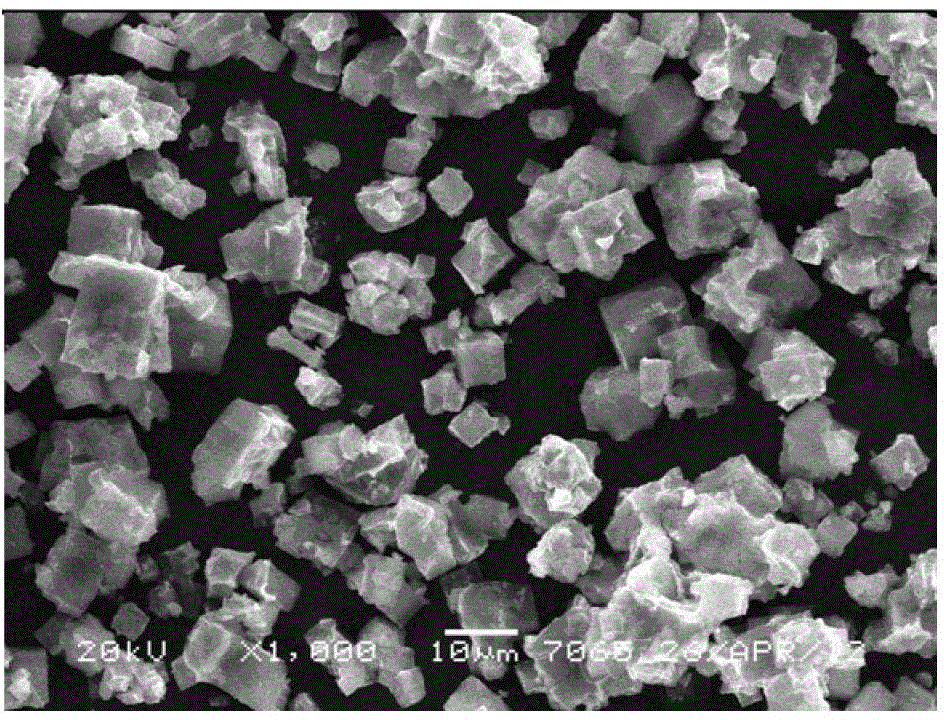

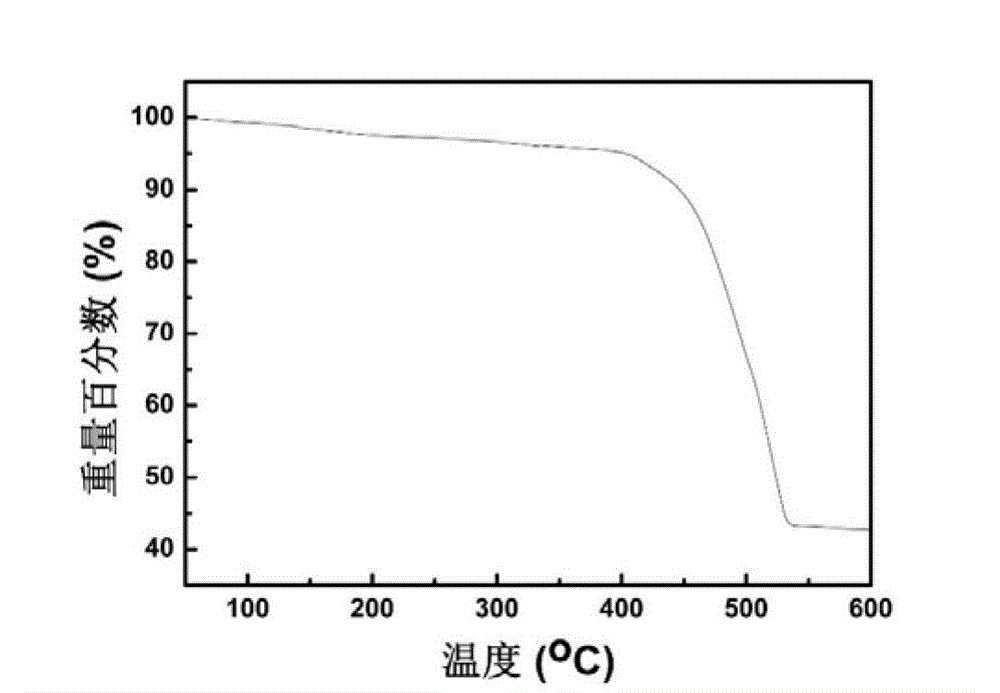

A MOF-5, terephthalic acid technology, applied in the direction of zinc organic compounds, can solve the problems of high equipment requirements and difficult to popularize, and achieve the effects of good particle consistency, simple operation and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

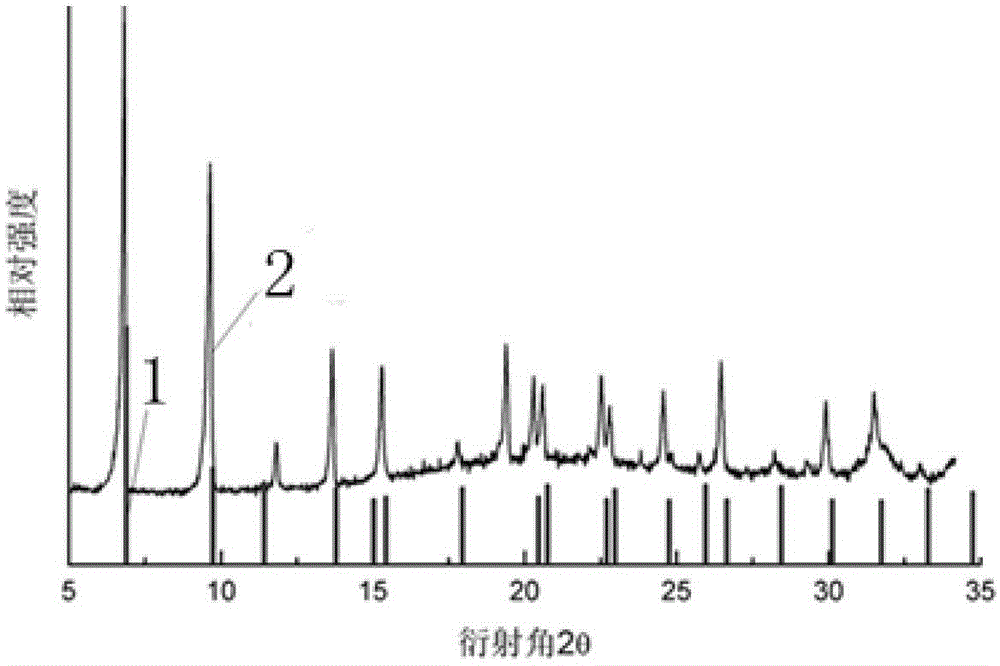

[0024] Weigh 3.06g zinc chloride and dissolve it in 50mL DMF to make solution A, weigh 2.5g terephthalic acid and dissolve it in 100mL DMF to make solution B, add 3mL triethylamine to B, mix well and heat B To 120°C, solution A was added dropwise to solution B at a rate of 120 μL / min, and the stirring rate was maintained at 400 r / min. After 7 hours, 3 g of MOF-5 was obtained, and the pH of the solution was 4 during the reaction. The Langmuir specific surface area of MOF-5 is 1563m 2 / g, its decomposition temperature by thermogravimetric analysis is 400°C.

Embodiment 2

[0028] Weigh 1.8g zinc acetate and dissolve it in 1000mL NMP to make solution A, weigh 0.5g terephthalic acid and dissolve it in 1000mL NMP to make solution B, add 3mL deionized water to B, mix well and heat B to 50 °C, solution A was added dropwise to solution B at a rate of 1.5 mL / min without stirring, and 0.5 g MOF-5 was obtained after 12 hours, and the pH value of the solution during the reaction was 4.5. The Langmuir specific surface area of MOF-5 is 2522m 2 / g, its decomposition temperature by thermogravimetric analysis is 400°C.

Embodiment 3

[0032] Weigh 5.65g zinc nitrate hexahydrate and dissolve it in 100mL DEF to make solution A, weigh 1.33g terephthalic acid and dissolve it in 100mL DEF to make solution B, heat A to 105°C, and drop B at 70μL / min Add it into solution A, keep the stirring speed at 200r / min, and obtain 1.9g MOF-5 after 24 hours, and the pH value of the solution is 5 during the reaction. Langmuir specific surface area is 2700m 2 / g, its decomposition temperature by thermogravimetric analysis is 400°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com