Method for producing anhydrous citric acid crystal

A technology of anhydrous citric acid and citric acid solution, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problem of difficult balance between evaporation and incoming and outgoing materials, unsatisfactory crystal particle size control, and small evaporation on the wall And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

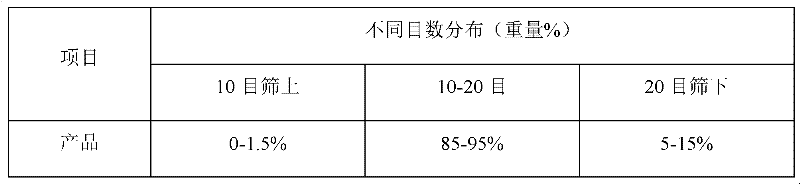

[0028] (1) will be 12.58m 3 The density is 1158kg / m 3 , The content of citric acid is the citric acid solution of 42% by weight, and the vacuum degree is -60kPa, and the citric acid solution temperature is 78 ℃ and concentrates to 5.9m 3The content of citric acid is the citric acid solution of 75.9% by weight, and the concentrated citric acid solution is introduced into the crystallizer and maintained at a temperature of 58-63°C (equivalent to a degree of supersaturation of 1.05-1.12). 7 kg of anhydrous citric acid seed crystals with a particle size of 150 μm were added to the solution and maintained for 1 hour.

[0029] (2) Under the condition that the vacuum in the crystallizer is -91kPa and the temperature is 58-63°C, the mixture obtained in step (1) is evaporated and crystallized. 3 The citric acid solution that citric acid content is 60% by weight is supplemented at the flow rate of / hour, and this flow rate makes the citric acid solution that contains anhydrous citric...

Embodiment 2

[0033] (1) will 10.5m 3 The density is 1202kg / m 3 , The content of citric acid is the citric acid solution of 50% by weight, and the vacuum degree is -50kPa, and the citric acid solution temperature is 85 ℃ and concentrates to 6.04m 3 The content of citric acid is the citric acid solution of 76.2% by weight, and the concentrated citric acid solution is introduced into the crystallizer and maintained at a temperature of 60-65°C (equivalent to a degree of supersaturation of 1.07-1.11). 31.5 kg of anhydrous citric acid seed crystals with a particle size of 180 microns were added to the solution and maintained for 1.5 hours.

[0034] (2) Under the conditions that the vacuum in the crystallizer is -90kPa and the temperature is 60-65°C, the mixture obtained in step (1) is evaporated and crystallized. 3 The flow rate of / hour supplements the citric acid solution that citric acid content is 50% by weight, and this flow rate makes the citric acid solution that contains anhydrous cit...

Embodiment 3

[0037] (1) will 20m 3 The density is 1095kg / m 3 , The content of citric acid is 30% by weight of citric acid solution, the vacuum is -50kPa, the temperature of citric acid solution is 85 ℃ and concentrated to 6.4m 3 The content of citric acid is the citric acid solution of 75.5% by weight, and the concentrated citric acid solution is introduced into the crystallizer and maintained at a temperature of 57-60° C. (equivalent to a degree of supersaturation of 1.07-1.12), and the 12.6 kg of anhydrous citric acid seed crystals with a particle size of 150 microns were added to the solution and maintained for 1.5 hours.

[0038] (2) Under the condition that the vacuum in the crystallizer is -93kPa and the temperature is 57-60°C, the mixture obtained in step (1) is evaporated and crystallized. 3 The citric acid solution that citric acid content is 65% by weight is supplemented at the flow rate of / hour, and this flow rate makes the citric acid solution that contains anhydrous citric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com