Preparation device for preparing functional micro-nano materials on silicon surfaces based on femtosecond laser and method

A femtosecond laser and preparation device technology, which is applied in the manufacture of microstructure devices, processes for producing decorative surface effects, microstructure devices, etc., can solve problems such as the limitation of the bandgap width of the absorption rate of silicon materials, and reduce heat dissipation. Damage, speed-up effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

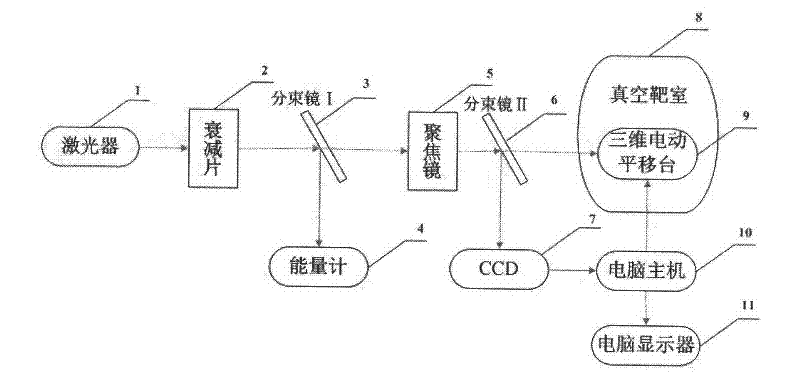

[0037] The preparation device and method of femtosecond laser-based silicon surface functional micro-nano materials of the present invention include: a laser 1, an attenuation plate 2, a first beam splitter 3, an energy meter 4, a focusing mirror 5, a second beam splitter 6, CCD7, vacuum target chamber 8, three-dimensional electric translation stage 9, computer mainframe 10 and display 11; wherein laser 1 is connected with attenuation sheet 2, first beam splitter mirror 3, focusing mirror 5, the first on the optical axis of its output beam in sequence Two beam splitters 6, a vacuum target chamber 8, and a three-dimensional electric translation platform 9.

[0038] The second beam splitting mirror 6 is connected with the energy meter 4; the focusing mirror 5 is connected with the CCD7; the CCD7 is connected with the computer host 10; the three-dimensional electric translation platform 9 is connected with the computer host 10;

[0039] Laser 1 is a femtosecond laser with a pulse...

Embodiment 2

[0055] Charge SF in step 2 6 The etching gas pressure is 10kPa; the rest are the same as in Embodiment 1.

Embodiment 3

[0057] Charge SF in step 2 6 The etching gas pressure is 20kPa; the rest are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com