Method for displaying original austenite grains of pipeline steel with strength grade of X70 and above

A technology of austenite grains and pipeline steel, which is applied in the display field of austenite grains, can solve the problems of difficulty in displaying the original austenite grains of pipeline steel, and achieve clear display and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

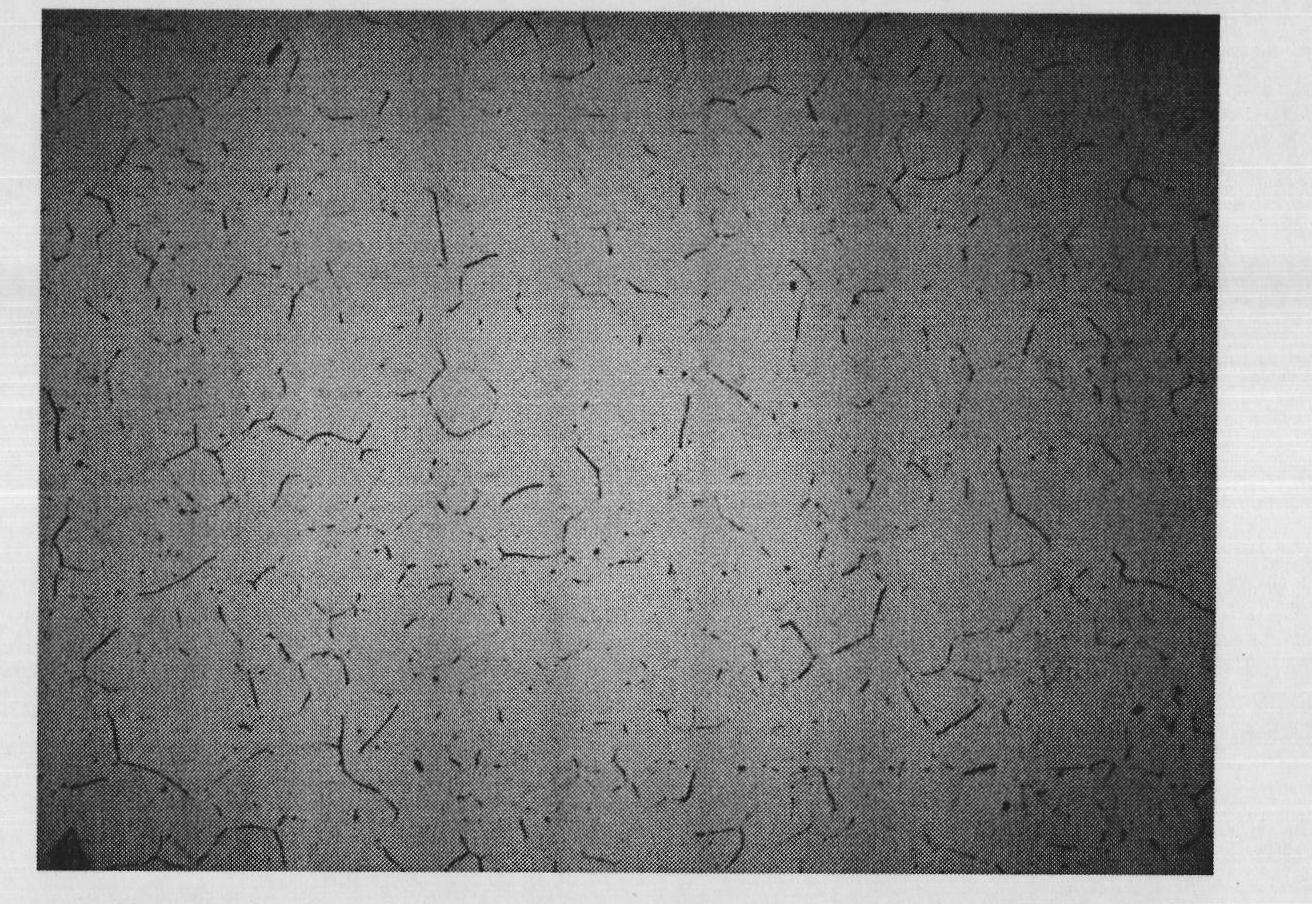

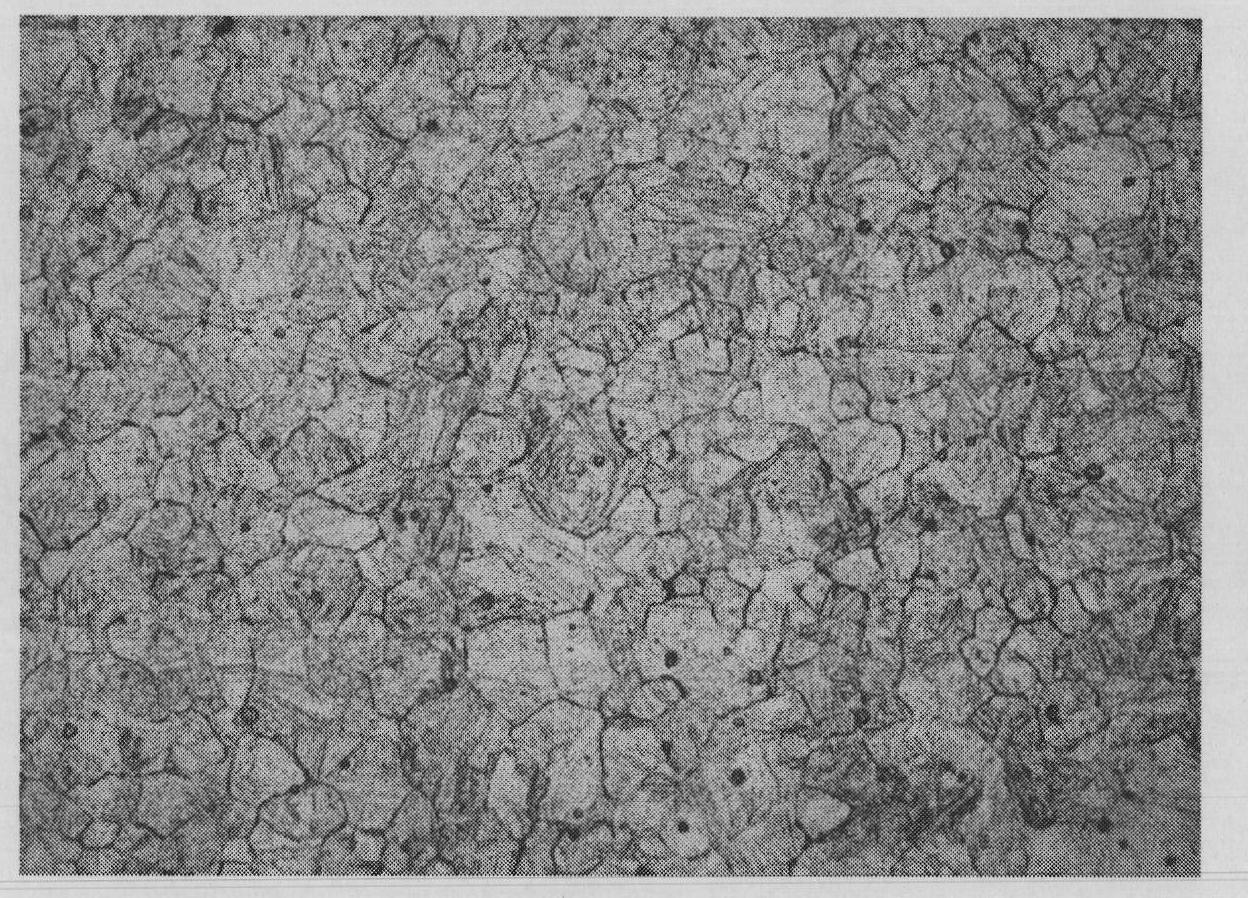

[0026] Example 1: Determination of the prior austenite grain size of a certain X70 pipeline steel

[0027] The technological process and steps of the present embodiment are as follows:

[0028] a Heat treatment: Process the material into a 15mm×15mm×20mm sample, place it in a box-type resistance furnace heated to 950°C, keep it warm for 0.5h, put it in NaCl aqueous solution for quenching, and take it out after it is completely cooled.

[0029] b Grinding and polishing: take the quenched sample to a grinder for preliminary grinding, after the rough ground sample is rinsed with clean water, then put the grinding surface on the metallographic sandpaper of each number from coarse to fine Perform fine sanding. Each time the next finer sandpaper is changed, the sample should be rotated 90° for grinding. Finally, the ground sample was cleaned and polished on a polishing machine until the polished surface was bright and traceless. The polishing agent is 1.5μm diamond polishing past...

Embodiment 2

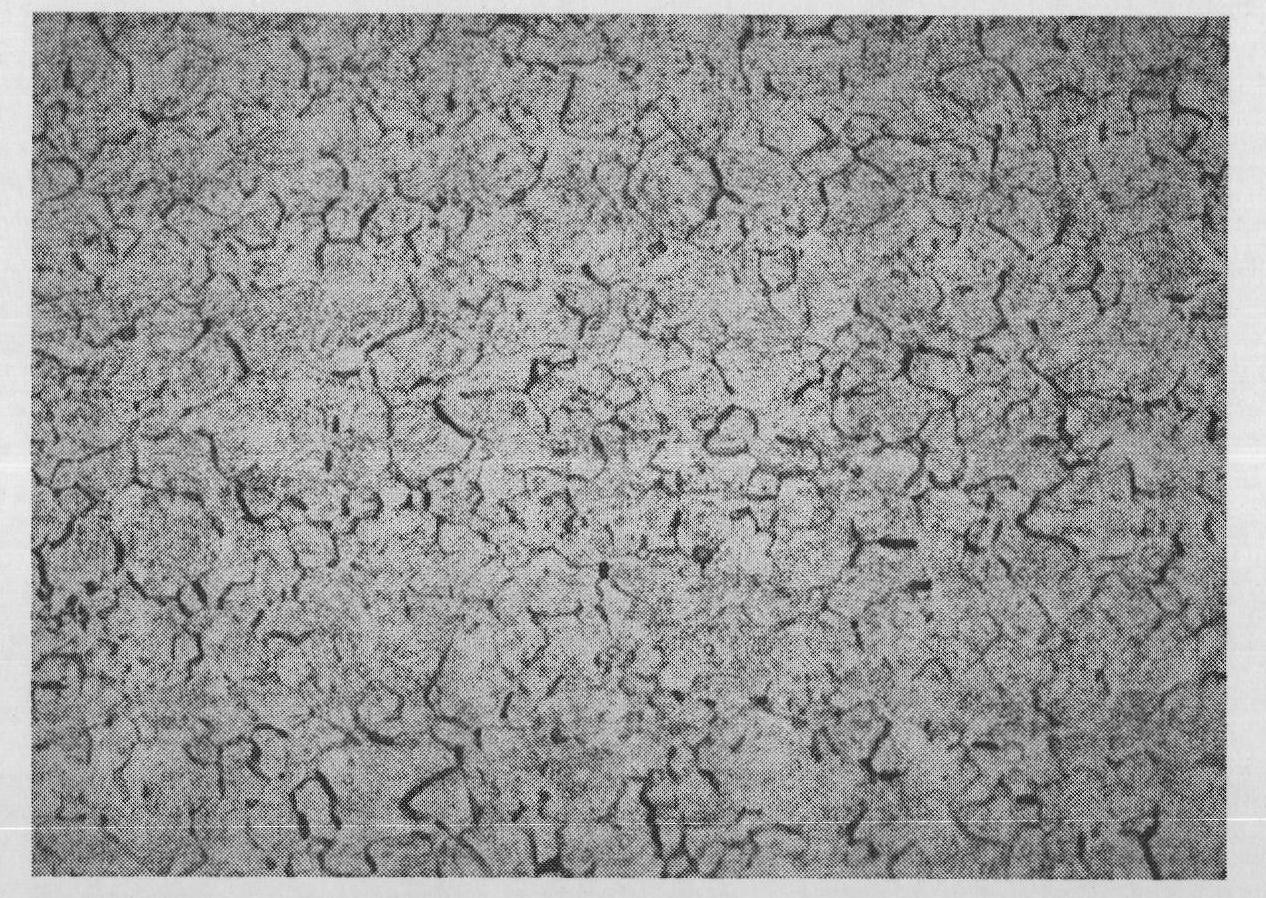

[0038] Example 2: Determination of the grain size of prior austenite in a certain X100 pipeline steel

[0039] a Heat treatment: Process the material into a 15mm×15mm×20mm sample, place it in a box-type resistance furnace heated to 950°C, keep it warm for 1 hour, put it in NaCl aqueous solution for quenching, and take it out after it is completely cooled.

[0040] b Grinding and polishing: take the quenched sample to a grinder for preliminary grinding, after the rough ground sample is rinsed with clean water, then put the grinding surface on the metallographic sandpaper of each number from coarse to fine Perform fine sanding. Each time the next finer sandpaper is changed, the sample should be rotated 90° for grinding. Finally, the ground sample was cleaned and polished on a polishing machine until the polished surface was bright and traceless. The polishing agent is 1.5μm diamond polishing paste, and water is used as lubricant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com