Method for testing autstenitic grain size of steel bainite structure for nuclear pressure vessel

A technology of austenite grain and pressure vessel, which is applied in the field of testing the bainite structure and austenite grain size of steel for nuclear pressure vessels, can solve the problem that the bainite structure and austenite grain size cannot be displayed, and the operation is complicated. and other problems to achieve the effect of optimizing the heat treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

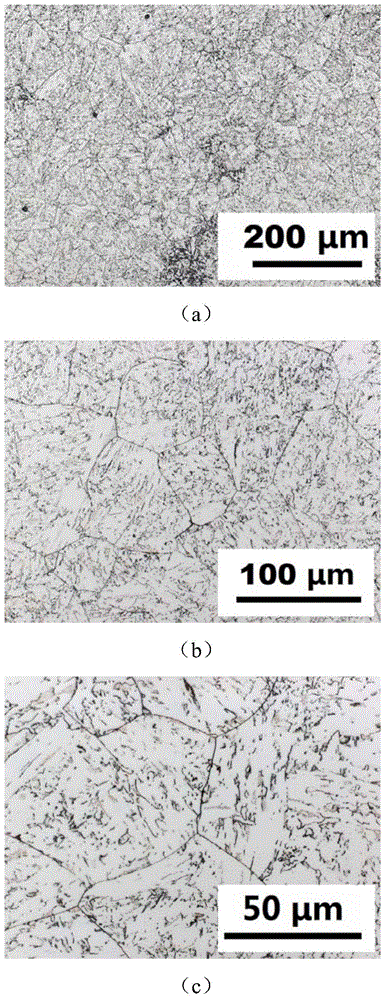

Embodiment 1

[0034] A method for testing the austenite grain size of steel bainite for nuclear electric pressure vessels, including preparation and polishing of metallographic samples, chemical etching of samples, sample observation and statistics of grain size, as follows :

[0035] 1) Preparation and polishing of metallographic samples:

[0036] a. Cutting and inlaying of metallographic samples: From the bulk samples taken from the actual forgings with austenitizing temperature of 1000℃, cut 10mm*10mm*5mm cubes by wire cutting and inlay them with bakelite powder , To prepare for subsequent polishing and polishing;

[0037] b. Coarse grinding of the sample: Grind the sample through 180#→320#→600# silicon carbide water-resistant sandpaper in sequence. The rotation speed of the grinding disc is set to 600rpm. Each time you change the sandpaper, you need to grind the sample along the surface. Rotate 90 degrees so that the new wear scar is perpendicular or nearly perpendicular to the last wear sca...

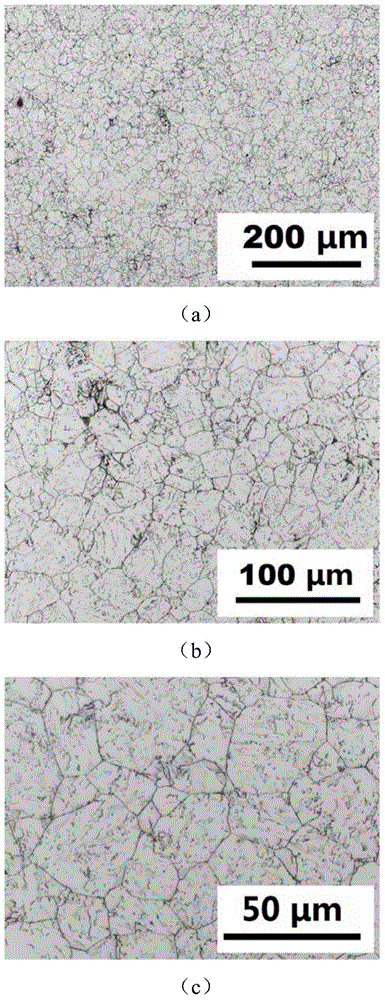

Embodiment 2

[0049] A method for testing the austenite grain size of steel bainite for nuclear electric pressure vessels, including preparation and polishing of metallographic samples, chemical etching of samples, sample observation and statistics of grain size, as follows :

[0050] 1) Preparation and polishing of metallographic samples:

[0051] a. Cutting and inlaying of metallographic samples: The large samples taken from the actual forgings with austenitizing temperature of 900℃ are used to cut the samples with the size of 10mm*10mm*20mm, because the sample Larger, no inlay is required, samples can be prepared by hand-held grinding and polishing;

[0052] b. Coarse grinding of the sample: Grind the sample through 180#→320#→600# silicon carbide water-resistant sandpaper in sequence. The rotation speed of the grinding disc is set to 500rpm. Each time you change the sandpaper, you need to grind the sample along the surface. Rotate 90 degrees so that the new wear scar is perpendicular or nearl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com