Medium-high carbon steel actual grain size developer and developing method

A grain size display, medium and high carbon technology, applied in measuring devices, material analysis by optical means, instruments, etc., can solve the delay of inspection time and inspection cost, insufficient surface contrast of metal samples, and unclear grain boundary display. and other problems, to achieve significant economic and social benefits, innovative ideas, simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

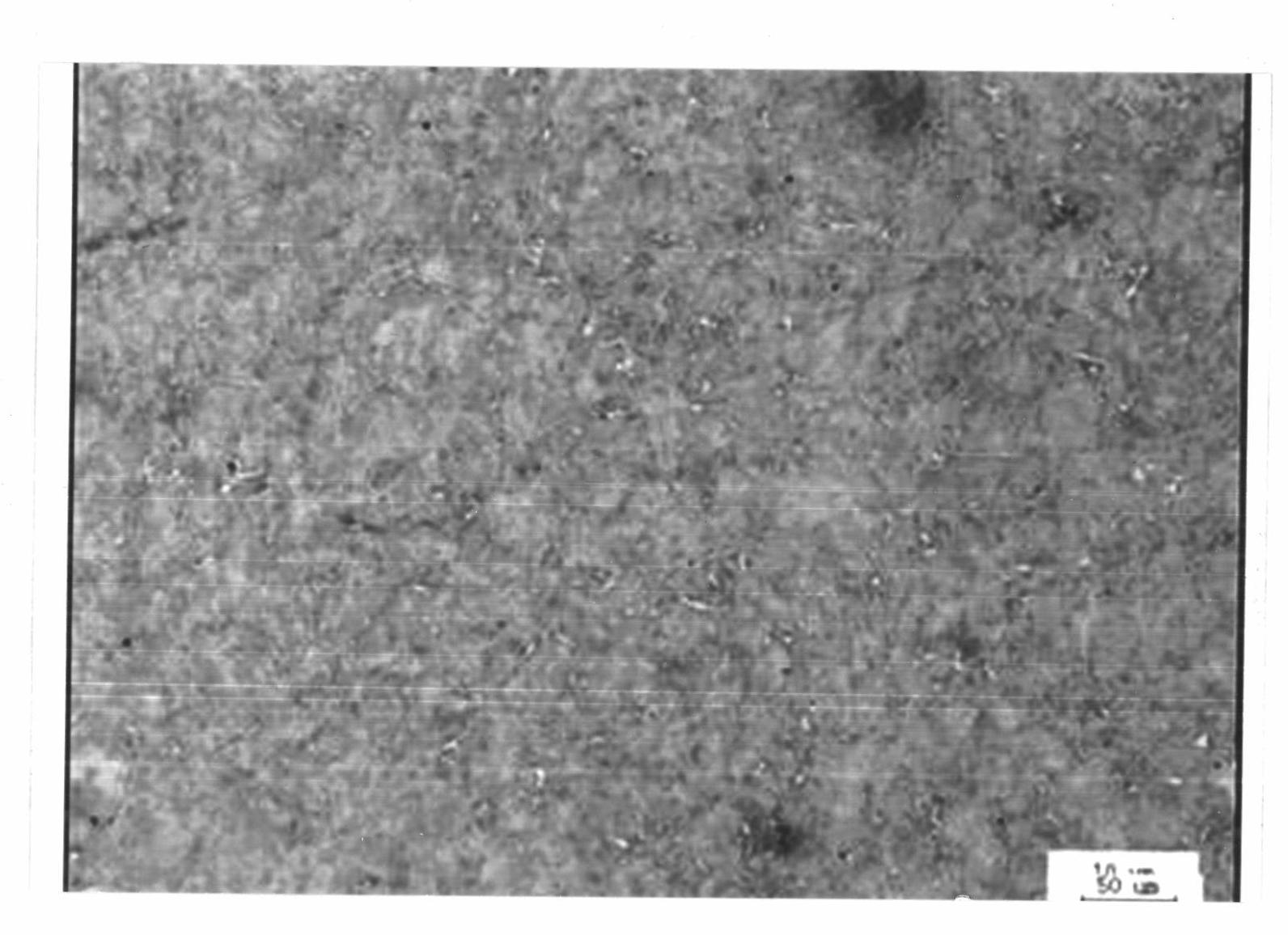

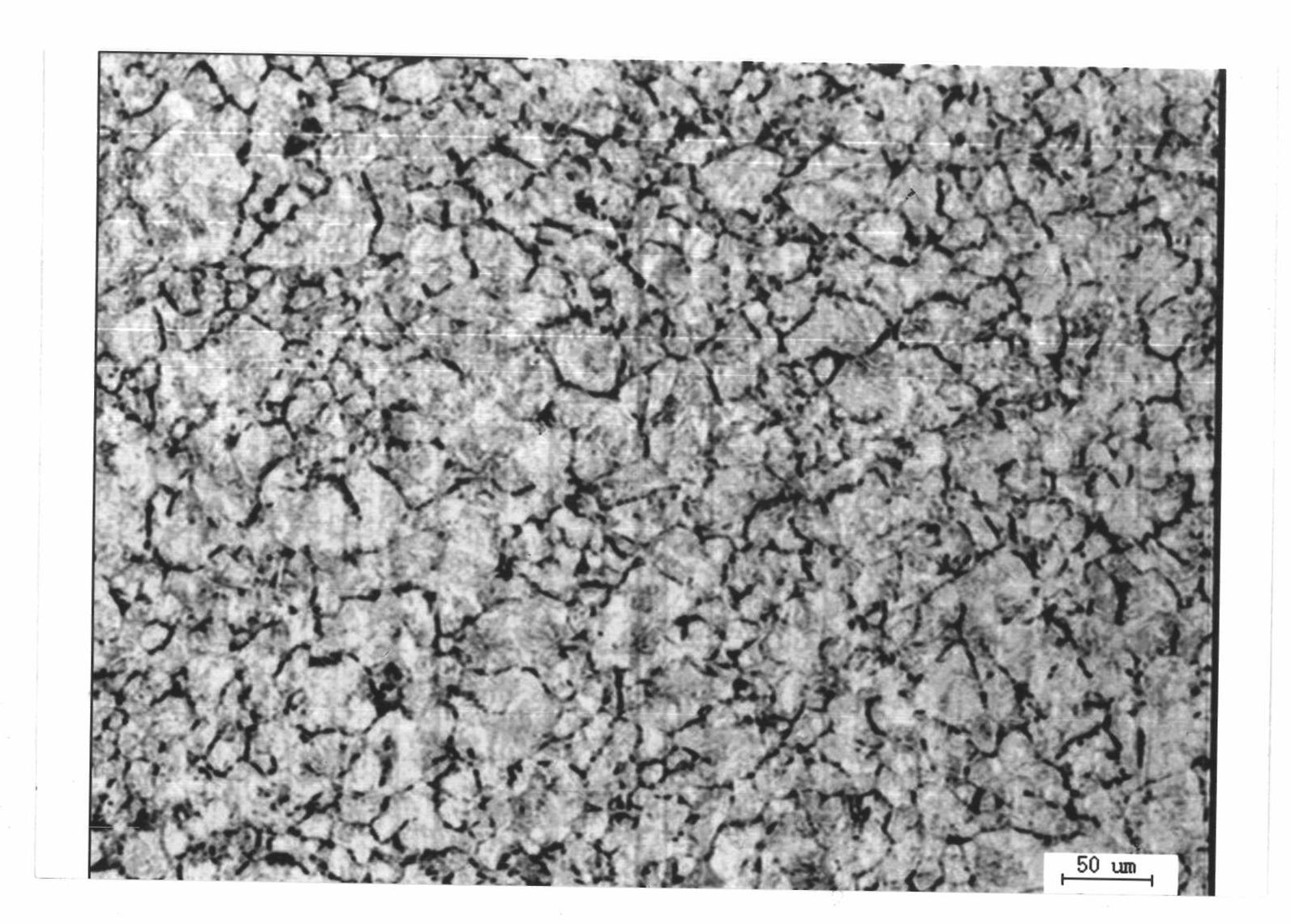

Embodiment 1

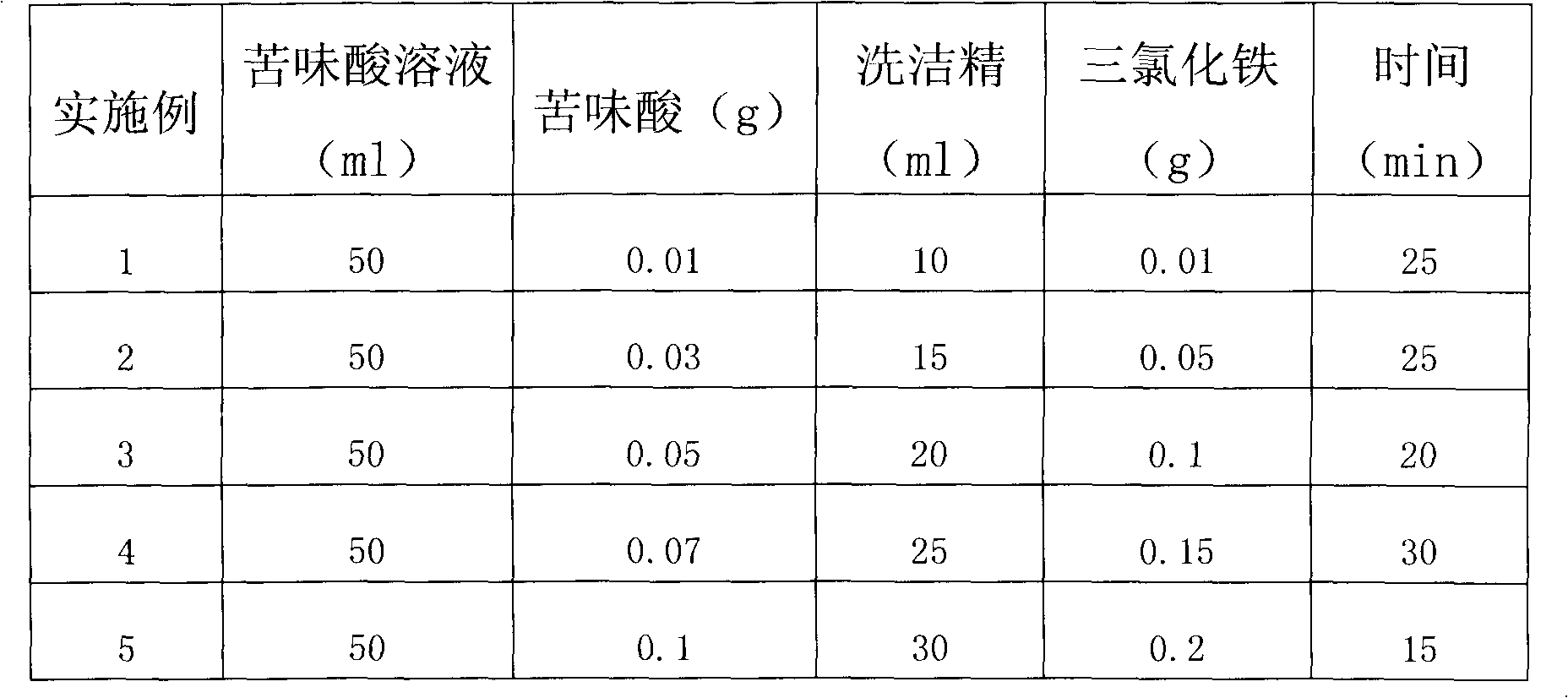

[0040] At a constant temperature of 30°C, first dissolve 2g of picric acid in 50ml of distilled water, and then dissolve them in the picric acid solution one by one in the order of 0.01g of picric acid, 10ml of detergent, and 0.01g of ferric chloride to prepare a display agent ; The prepared sample is placed in a container filled with a display agent solution, corroded for 25 minutes, the surface of the sample is dark gray, cleaned and polished; then microscopic observation and electronic image collection are carried out. The composition and erosion time of the revealing agent are listed in Table 1.

Embodiment 2

[0041] Embodiment 2 is implemented with the method of embodiment 1, and its composition and corrosion time are listed in table 1.

Embodiment 3

[0042] Embodiment 3 is implemented with the method of embodiment 1, and its composition and corrosion time are listed in table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com