Method for displaying original austenitic grain boundary of martensitic heat-resistant steel

A technology of austenitic grain boundaries and heat-resistant steel, which is applied in the field of metallographic sample preparation, can solve problems such as chronic poisoning, contact dermatitis, and low flash point, and achieve the effect of fast etching speed and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

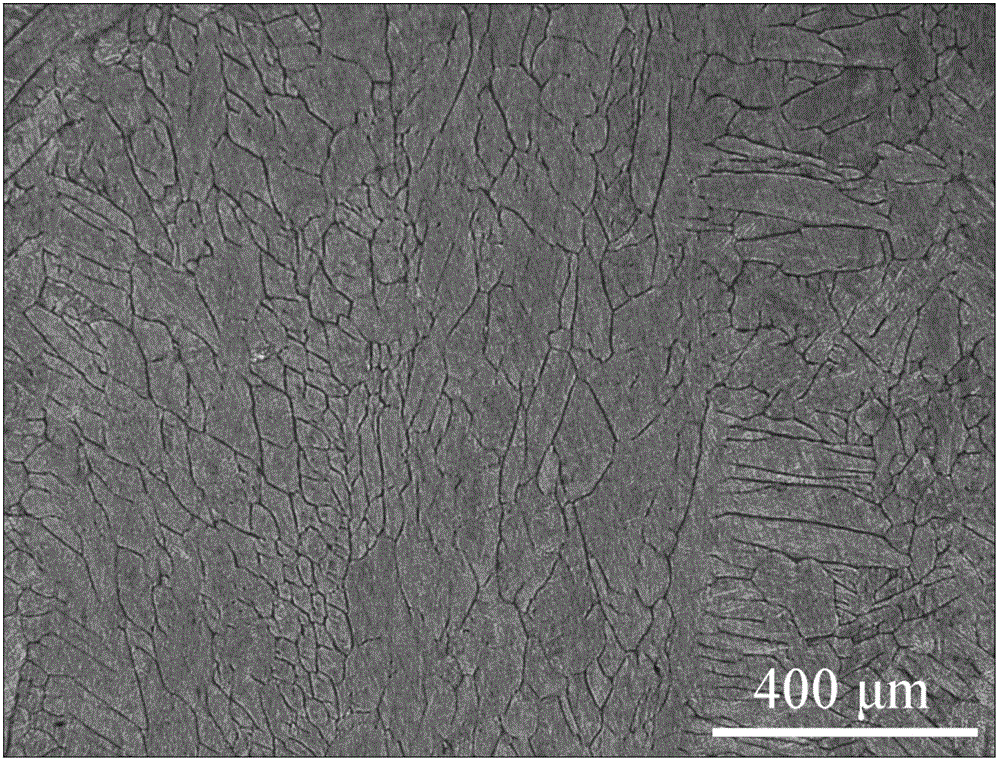

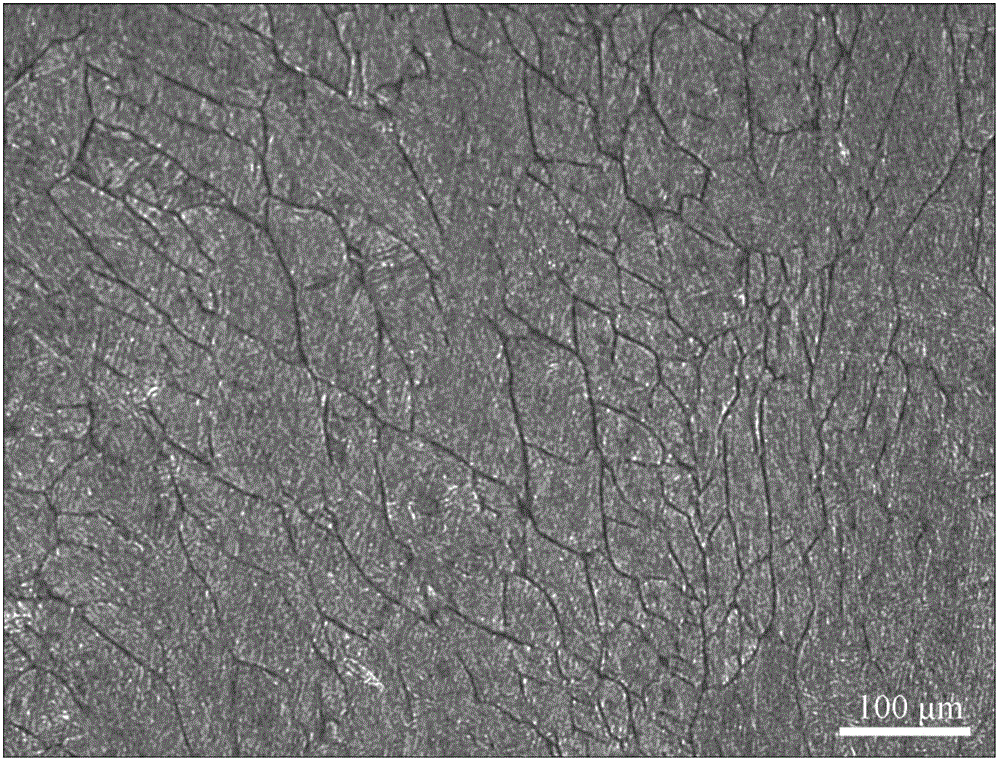

Image

Examples

Embodiment Construction

[0015] The technological process and steps of the present embodiment are as follows:

[0016] 1 coarse grinding - fine grinding: the sample taken from the ingot at 400 # →600 # →800 # →1000 # →1200 # →1500 # →2000 # Sanding with silicon carbide metallographic sandpaper. Every time the sand paper is changed during grinding, the sample should be rotated 90o in the same direction, and the surface of the sample should be observed frequently to ensure that there are no large scratches on the surface perpendicular to the grinding direction. Grinding is over when the new sandpaper wear marks completely cover the wear marks of the previous sand paper.

[0017] 2 Mechanical polishing: First, will go through 2000 # Rinse the polished sample with silicon carbide metallographic sandpaper with clean water to avoid sand particles remaining on the surface of the sample and affect the polishing quality. Then place the sample on a polishing cloth for polishing. First use 2.5μ diamond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com