Original crystalline grain displaying agent of high-alloy and low-carbon martensite steel and displaying method

A technology of martensitic steel and display agent, which is applied in particle size analysis, particle and sedimentation analysis, measuring devices, etc., can solve the problems of difficult corrosion, few documents, and inapplicability of high-alloy low-carbon martensitic steel, etc., and achieve operational Simple, novel idea, complete grain boundary display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

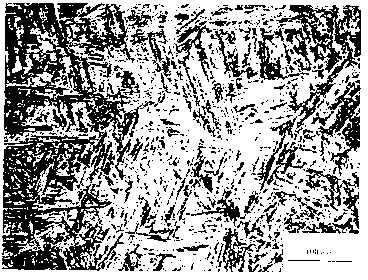

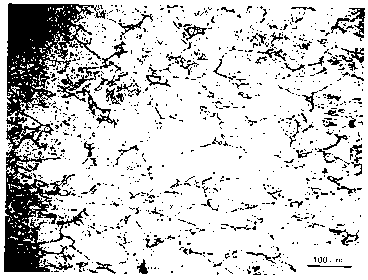

Image

Examples

preparation example Construction

[0013] I. Sample preparation:

[0014] a. Sampling

[0015] The sample is taken directly from the steel in the delivery state, and the structural change caused by the temperature rise must be prevented when sampling. The principle of sample size selection is to facilitate the operation of grinding, polishing and tissue observation. For example, cylindrical samples of φ10×15mm or φ15×18mm can also be used for 10×10×15mm or 12×15×18mm. Cuboid sample.

[0016] b. Grinding sample

[0017] Use metallographic sandpaper or water sandpaper of different meshes to grind the surface of the sample for multiple passes. The meshes of the sandpaper are in order from small to large, and the mesh of the last grinding sample is generally 1000 or 1200.

[0018] c. Polishing

[0019] Mechanical polishing, using polishing agent and woolen cloth to polish on the polishing machine, using water to lubricate and wet the woolen cloth during polishing, and polish until the surface of the sample is s...

Embodiment 1

[0033] At room temperature of 25°C, first measure 5ml concentrated nitric acid (concentration 65 mass%), pour into 50ml (purity 95 mass%) industrial alcohol and shake well, add 15ml concentrated hydrochloric acid (36 mass%) and shake well, pour Place in an airtight glass container. Before the sample is corroded, take out the prepared above-mentioned solution, add 1 gram of picric acid, stir and shake well, then add 1.5 grams of sodium dodecylbenzene sulfonate, stir and shake well. Pour an appropriate amount of the prepared etchant solution into the evaporating dish, place a thin layer of absorbent cotton (immersed in the solution) in the evaporating dish, and place the 1Cr12Ni1Mo steel surface of the sample to be corroded on the absorbent cotton to avoid contact between the sample and the glassware wall , the erosion time was controlled at 8 min, and then the sample was taken out to wipe the surface with alcohol, dried with hot air, and then microstructure observation and elec...

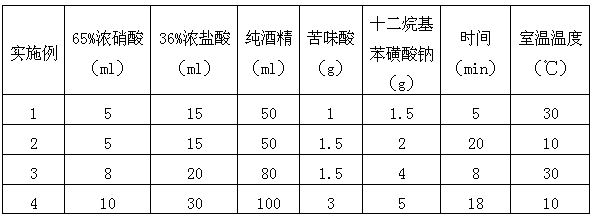

Embodiment 2

[0034] Embodiment 2 is implemented with the method of Embodiment 1, and its composition ratio and corrosion conditions are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com