A kind of corrosive agent for nuclear power steel 16mnd5 steel grain size and its corrosion manifestation method

A 16MND5, corrosion display technology, used in particle size analysis, preparation of test samples, particle and sedimentation analysis, etc., can solve the problem of unclear grain size and grain boundary, and achieve clear grain boundary display effect, novel concept, and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

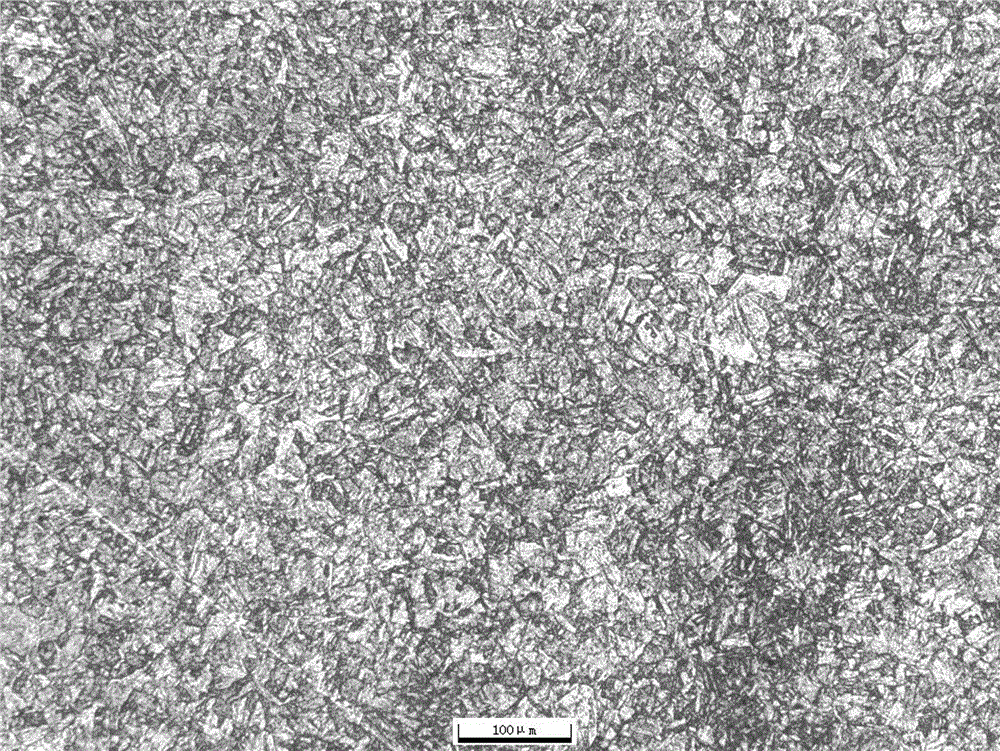

[0027] This embodiment discloses a corrosive agent for nuclear power steel 16MND5 steel grain size, the specific components of the corrosive agent are: picric acid 5g, xylene 50ml, ethanol 5ml, the configuration method of the corrosive agent is first in a beaker with a specification of 100ml Pour in 5ml of ethanol, then pour in 50ml of xylene, and finally put in about 5g of picric acid, and finally stir evenly with a glass rod to obtain the required etchant.

[0028] The invention also discloses a method for developing the corrosion of the above-mentioned corrosive agent. The specific method for developing the corrosion of the 16MND5 steel grain size of nuclear power steel by using the corrosive agent is as follows: grinding and polishing a sample of the 16MND5 steel grain size, and configuring the corrosive agent; Put the polished surface of the prepared grain size sample into the etchant and completely immerse it in the etchant, otherwise increase the etchant until the sample...

Embodiment 2

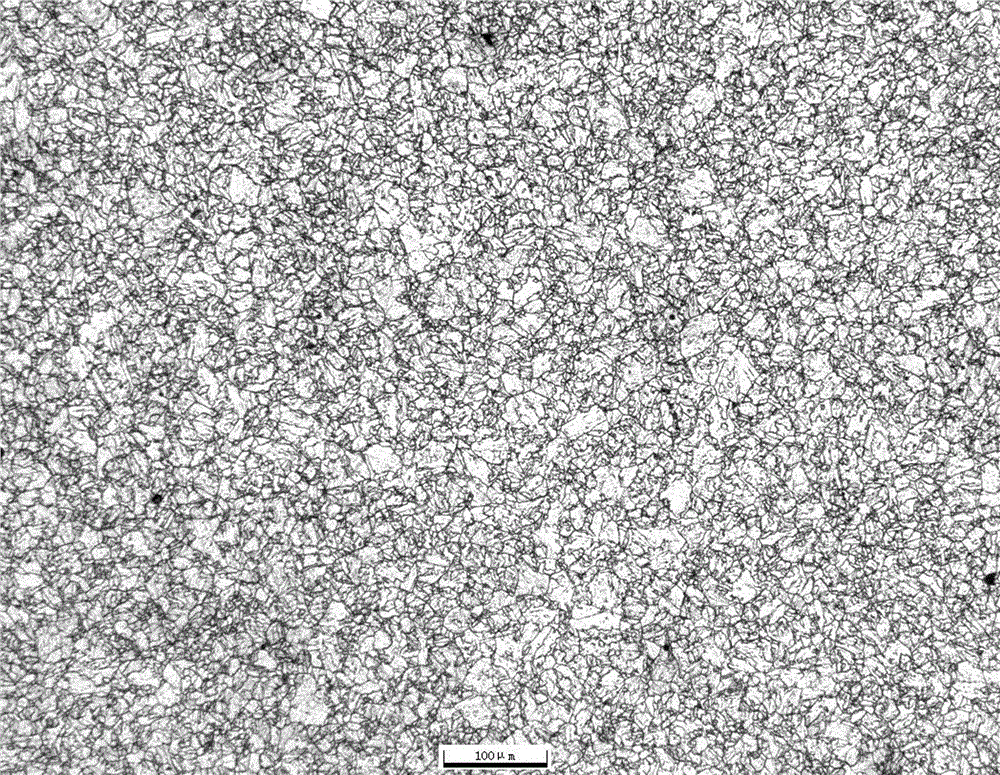

[0033] In this embodiment, on the basis of the above-mentioned embodiment, the components of the corrosive agent are adjusted, which are 5g of picric acid, 20ml of xylene, and 60ml of ethanol, and are configured according to the method in the above-mentioned embodiment, and then the nuclear power steel 16MND5 steel grain The degree of specific corrosion appearance, the grain boundary effect diagram of the grain size displayed by the corrosion appearance method is as follows image 3 shown.

[0034] Depend on image 3 and figure 2 It can be seen from the comparison that in the case of reducing xylene and increasing ethanol, that is, after etching with 5 g of picric acid, 20 ml of xylene, and 60 ml of ethanol, the corrosion effect of the grain boundary can also be clearly displayed, but compare figure 2 The corrosion effect diagram in the figure is relatively blurred, but it can also meet the requirements of accurately assessing the grain size level of 16MND5 steel for nucl...

Embodiment 3

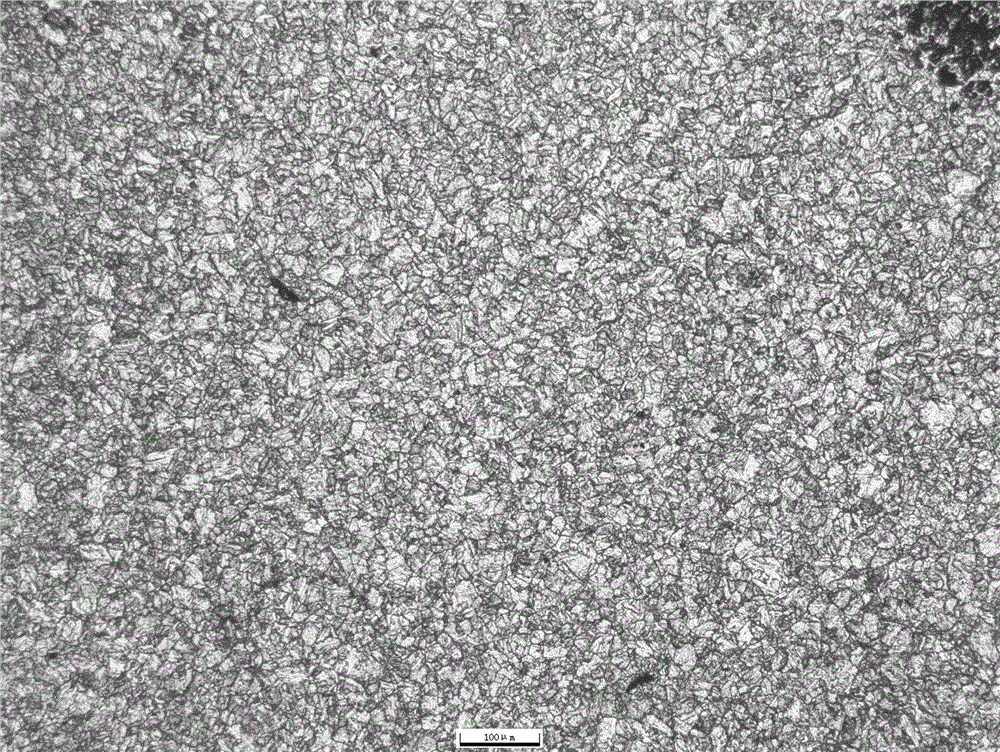

[0036] In this embodiment, on the basis of the above-mentioned embodiment, the components of the corrosive agent are adjusted, which are 3g of picric acid, 30ml of xylene, and 60ml of ethanol, which are configured according to the method in the above-mentioned embodiment, and then the nuclear power steel 16MND5 steel grain The degree of specific corrosion appearance, the grain boundary effect diagram of the grain size displayed by the corrosion appearance method is as follows Figure 4 shown.

[0037] Depend on Figure 4 It can be seen that after reducing the content of picric acid and increasing the content of xylene and ethanol, that is, picric acid is 3g, xylene is 30ml, and ethanol is 60ml of etchant after corrosion, the grain boundary display effect is also relatively clear, and it can also Accurately and clearly display the corrosion effect of the grain boundary.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com