High aluminum zinc alloy etching agent and use method thereof

An etchant and zinc alloy technology, applied in the field of metallographic sample preparation, can solve problems such as over-corrosion, difficulty in displaying grain boundaries, and difficulty in microstructure analysis, and achieve the effect of clear and easy-to-distinguish grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

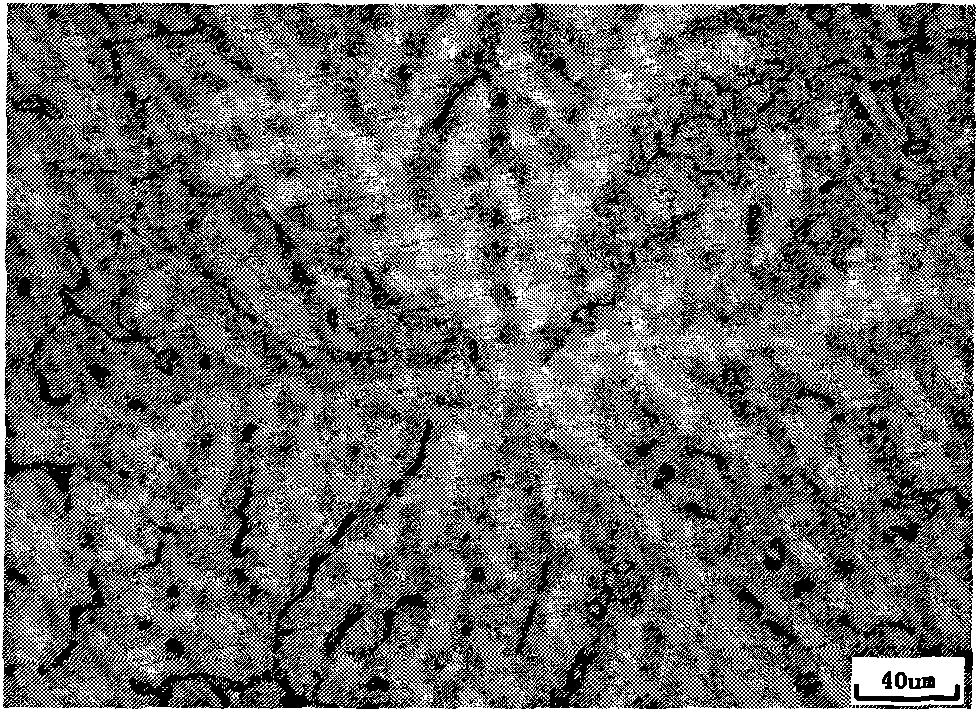

Embodiment 1

[0024] [Sample] High aluminum zinc alloy

[0025] [Processing state] As cast

[0026] [Formulation and process parameters]

[0027] Nitric acid (mass fraction: 68%) 2ml

[0028] Hydrochloric acid (mass fraction: 38%) 4ml

[0029] Glacial acetic acid (mass fraction: 99%) 8ml

[0030] Deionized water 10ml

[0031] Anhydrous ethanol (mass fraction: 99.5%) 76ml

[0032] Picric acid 2g

[0033] Corrosion time 3 seconds

[0034] Temperature room temperature

[0035] Take a 200ml glass beaker, first add the above metered absolute ethanol into the beaker, then add picric acid, hydrochloric acid, nitric acid, glacial acetic acid and deionized water according to the above metered amount, mix and stir evenly.

[0036] [Processing Procedure]

[0037] (1) Polishing: After rough grinding and fine grinding, the high-aluminum-zinc alloy samples are polished on a metallographic polishing machine. The polishing material used is a diamond spray polishing agent and anhydrous ethanol is added to assist polishing.

...

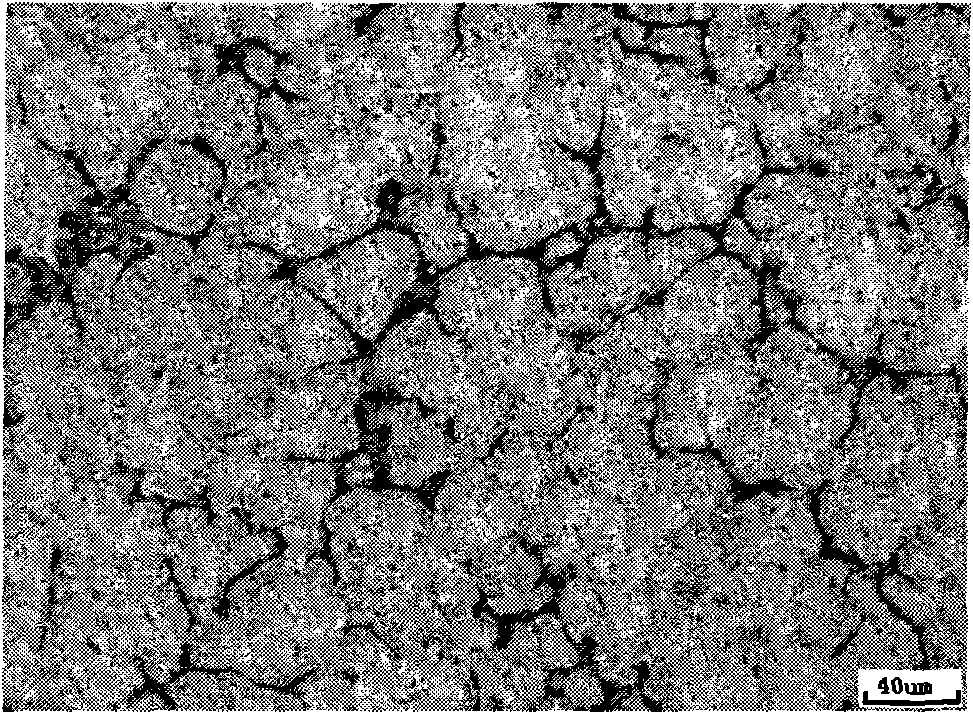

Embodiment 2

[0043] [Sample] Same as Example 1

[0044] [Processing state] Solution treatment

[0045] [Formulation and process parameters]

[0046] Nitric acid (mass fraction: 65%) 2ml

[0047] Hydrochloric acid (mass fraction: 36%) 4ml

[0048] Glacial acetic acid (mass fraction: 99%) 8ml

[0049] Distilled water 10ml

[0050] Anhydrous ethanol (mass fraction: 99.5%) 76ml

[0051] Picric acid 2g

[0052] Corrosion time 3 seconds

[0053] Temperature room temperature

[0054] Take a 200ml glass beaker, first add the above-mentioned metered absolute ethanol into the beaker, then add picric acid, hydrochloric acid, nitric acid, glacial acetic acid and distilled water according to the above-mentioned meter, mix and stir evenly.

[0055] [Processing Procedure] Same as Example 1

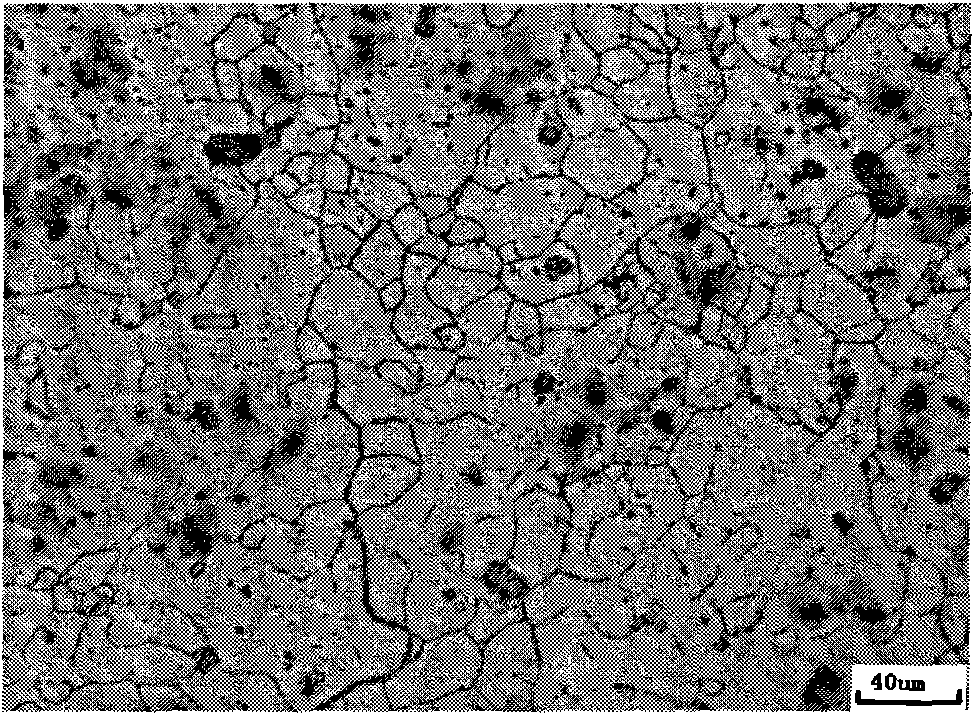

Embodiment 3

[0057] [Sample] Same as Example 1

[0058] [Processing state] Solution treatment

[0059] [Formulation and process parameters]

[0060] Nitric acid (mass fraction: 65%) 2ml

[0061] Hydrochloric acid (mass fraction: 36%) 3ml

[0062] Glacial acetic acid (mass fraction: 99%) 10ml

[0063] Deionized water 10ml

[0064] Anhydrous ethanol (mass fraction: 99.5%) 75ml

[0065] Picric acid 3g

[0066] Corrosion time 5 seconds

[0067] Temperature room temperature

[0068] Take a 200ml glass beaker, first add the above metered absolute ethanol into the beaker, then add picric acid, hydrochloric acid, nitric acid, glacial acetic acid and deionized water according to the above metered amount, mix and stir evenly.

[0069] [Processing Procedure] Same as Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com