Aggressive agent for displaying solidification genetic dendritic structure in high-carbon steel plate strip and display method

A technology of dendrite structure and etchant, which is applied in the field of metallographic inspection and analysis, can solve the problems of not being able to obtain the real solidification structure of the continuous casting slab of wire rod and the solidification condition of the continuous casting slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The analysis in this embodiment is the SWRH82B steel wire rod produced by a steel factory, and the carbon content is 0.82wt%.

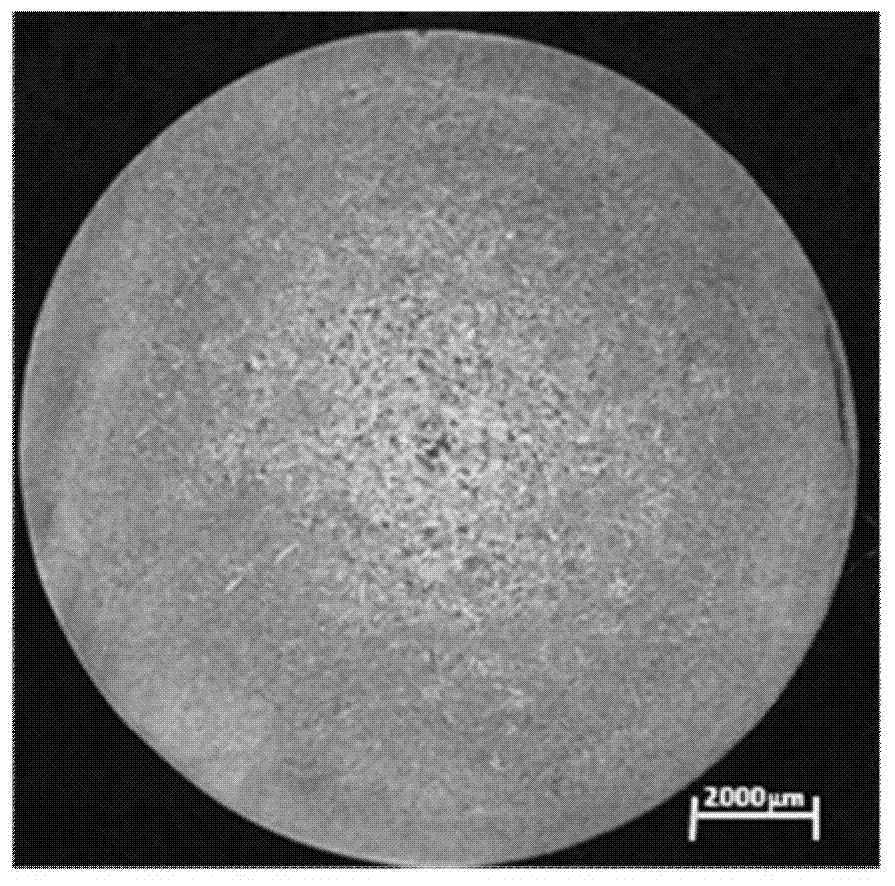

[0018] After grinding the sample with a grinding wheel, grind it on 180#, 400#, 800# and 1000# water sandpaper in turn, and then polish it with 2.5μm and 1μm diamond grinding paste on the polishing disc until the surface of the sample is smooth without obvious scratches until. After polishing, rinse the surface with alcohol, wipe the stains on the surface of the sample with cotton, and then dry it with a hair dryer. Add 5.5g of water-sealed picric acid of analytical grade (purity ≥ 99.8%) into 100ml of distilled water, then add 10ml of white cat detergent, and stir evenly. Put the prepared etchant into a constant temperature water bath, heat and stabilize at 65°C. Put the surface of the prepared sample upwards, immerse in the etchant and corrode for about 13 seconds. After observing that the surface of the sample becomes dark, immediately tak...

Embodiment 2

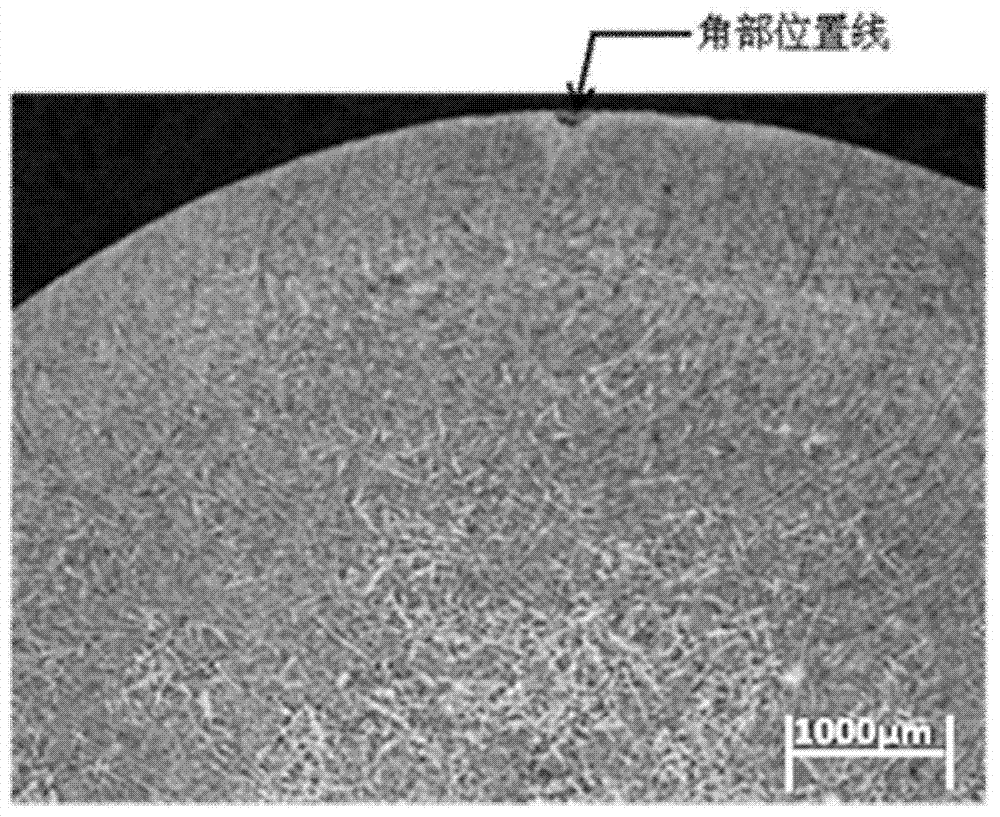

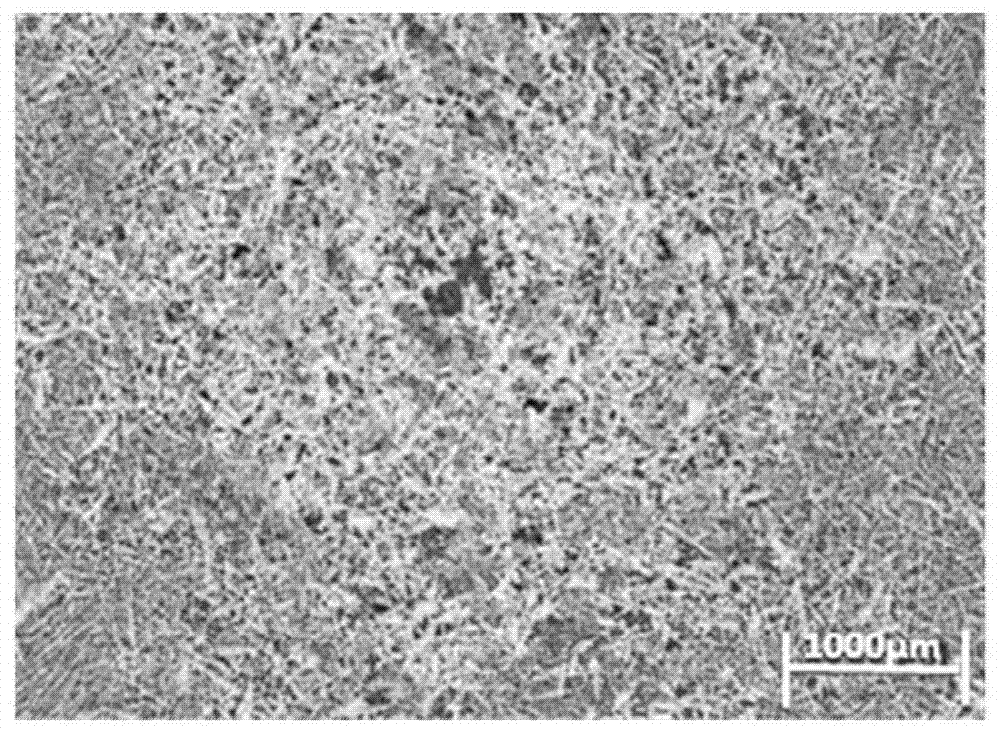

[0020] This example analyzes the SWRH82B steel wire rod (with surface scarring defects) produced by a steel factory, with a carbon content of 0.82wt%

[0021] After grinding the sample with a grinding wheel, grind it on 180#, 400#, 800# and 1000# water sandpaper in turn, and then polish it with 2.5μm and 1μm diamond grinding paste on the polishing disc until the surface of the sample is smooth without obvious scratches until. After polishing, rinse the surface with alcohol, wipe the stains on the surface of the sample with cotton, and then dry it with a hair dryer. Add 7g of analytically pure (purity ≥ 99.8%) picric acid sealed in water into 100ml of distilled water, then add 25ml of white cat detergent, and stir evenly. Put the prepared etchant into a constant temperature water bath, heat and stabilize at 72°C. Put the surface of the prepared sample upwards, immerse in the etchant and corrode for about 20 seconds. After the surface of the sample is observed to become dark, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com