Hot-working die large round billet and preparation method thereof

A hot work die and round billet technology, applied in the metallurgical field, can solve the problems of easy head warping, high hardness, large alloy content, etc., and achieve the effect of small heat treatment deformation and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

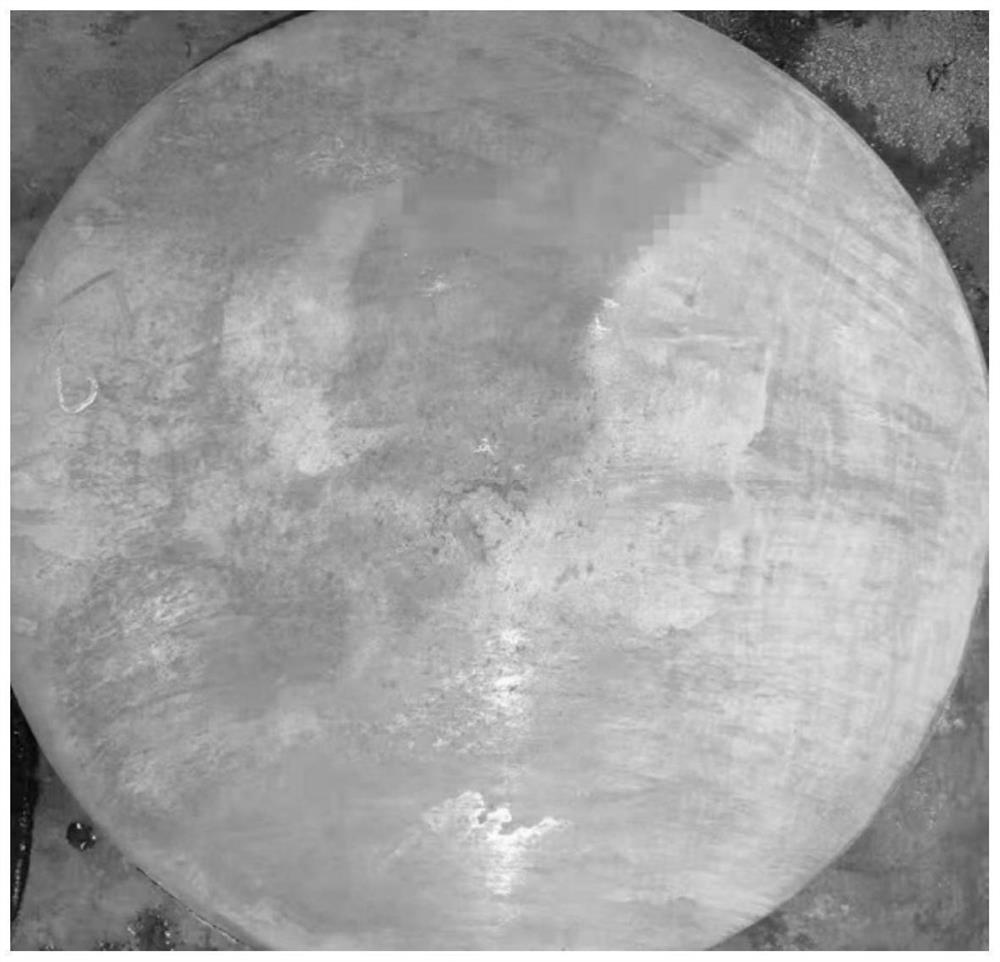

Image

Examples

Embodiment 1-6

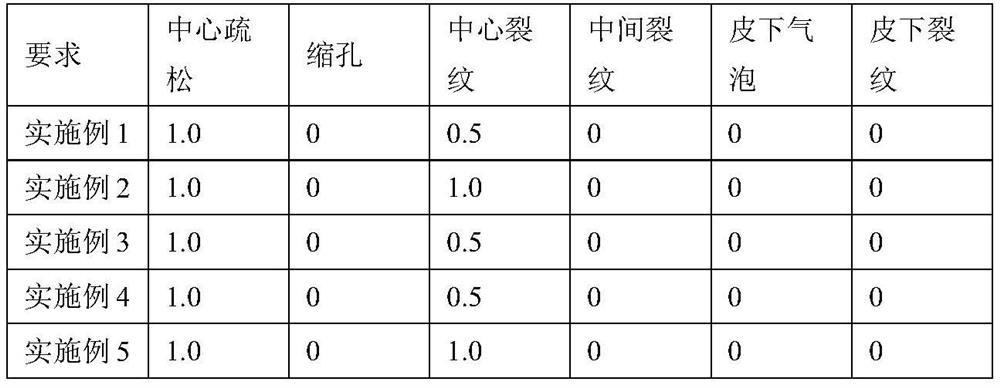

[0027] Embodiments 1-6 provide a method for producing a hot-work mold large round blank, and its chemical composition is shown in Table 1.

[0028] Table 1 Example 1-6 The chemical composition table of the hot work mold large round billet

[0029] Require C Si mn P S Cr Mo V Ca Al Ti Example 1 0.50 0.95 0.27 0.014 0.002 4.90 1.33 0.98 0.0026 0.018 0.003 Example 2 0.49 0.95 0.28 0.012 0.001 4.89 1.34 0.97 0.0019 0.021 0.003 Example 3 0.51 0.96 0.28 0.015 0.001 4.94 1.39 0.96 0.0061 0.023 0.004 Example 4 0.51 0.99 0.27 0.013 0.003 4.94 1.34 0.97 0.0058 0.018 0.003 Example 5 0.51 0.98 0.27 0.011 0.002 4.93 1.34 0.96 0.0021 0.019 0.004 Example 6 0.50 0.98 0.28 0.014 0.002 4.90 1.36 0.95 0.0015 0.019 0.003

[0030] Table 2 shows the alkalinity of the refining slag of hot-working mold blooms in Examples 1-6.

[0031] Table 2 Basicity of refining slag of hot w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com