Method for forecasting continuous-casting-production casting blank microstructure

A billet and continuous casting technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as poor model portability, difficulty in secondary development, and difficulty in meeting the requirements for solidification structure control of steel continuous casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

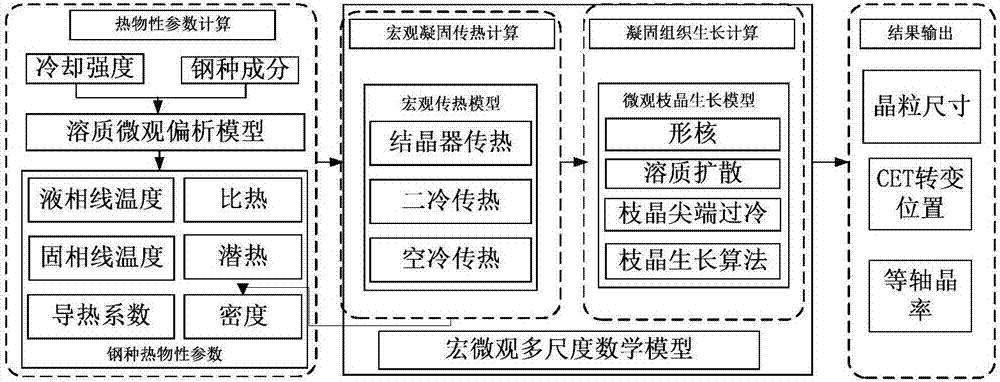

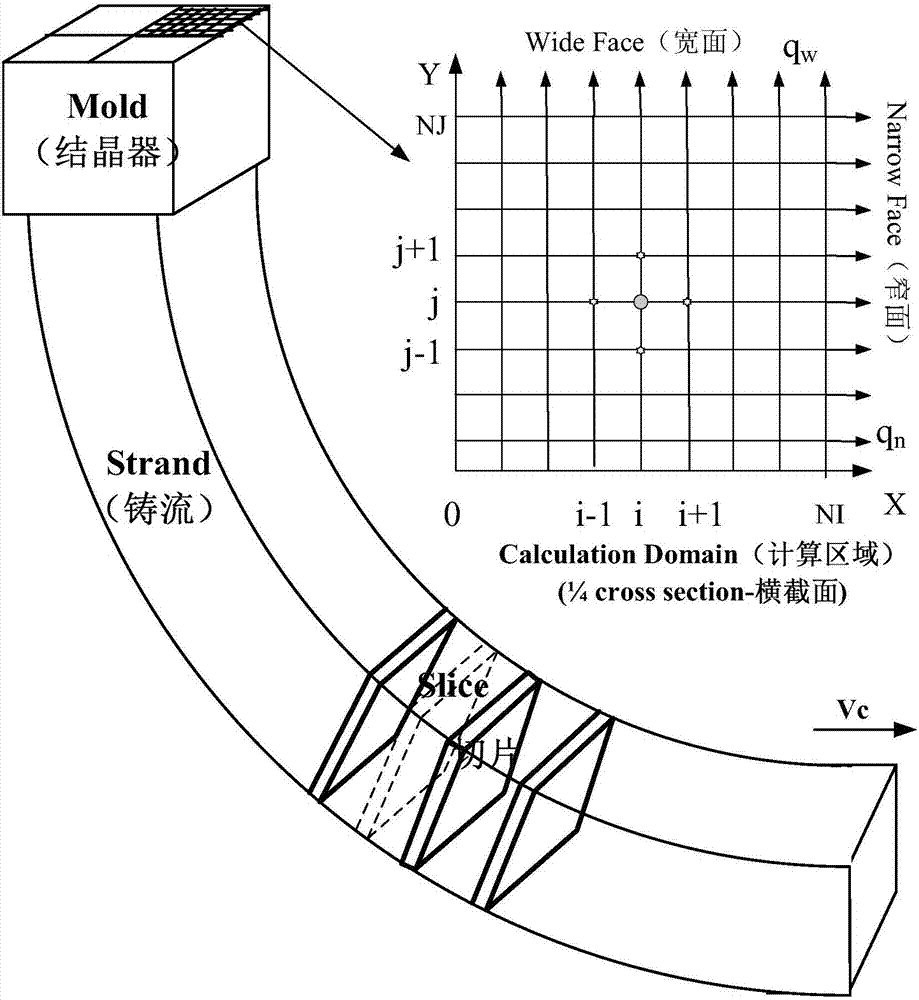

[0085] combine Figure 1 to Figure 3 As shown, the prediction method of this embodiment can be composed of four parts: calculation of thermal physical property parameters, calculation of macroscopic solidification heat transfer, calculation of solidified tissue growth, and output of results.

[0086] (1) Calculation of thermophysical parameters

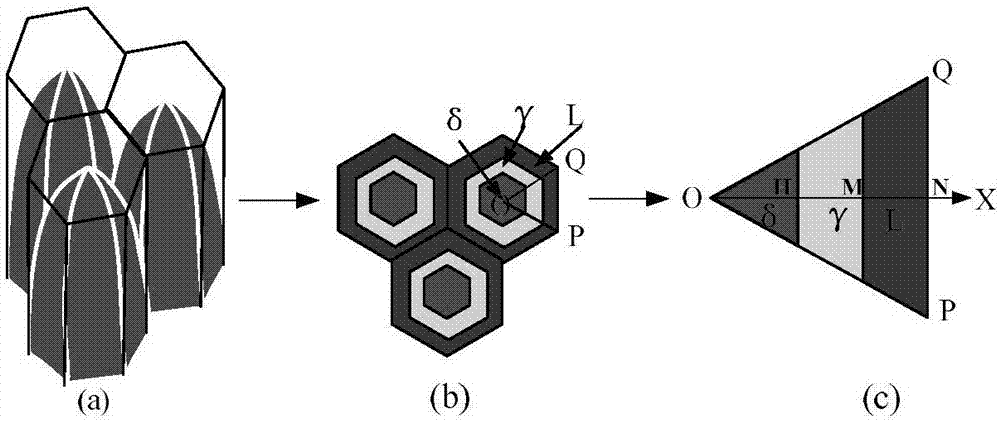

[0087] figure 2 A schematic diagram of dendrite growth in steel continuous casting slabs is shown. exist figure 2 In this method, assuming that the cross section of the dendrite morphology is a regular hexagon, firstly, a mathematical model of solute micro-segregation is established based on the principle of solute conservation between dendrites and the principle of solute diffusion;

[0088] Then, according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com