Macroscopic sampling method of microalloying high-strength steel slabs for cars

A micro-alloying, high-strength technology applied in the field of metal materials to reduce cost losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A method for low-magnification sampling of micro-alloyed high-strength automotive steel slabs, specifically:

[0016] First, the billet is cut off-line in a cold state, and then processed by a milling machine. The thickness of the milling machine is controlled to be greater than 35mm and the roughness of the inspection surface is less than 1.6μm.

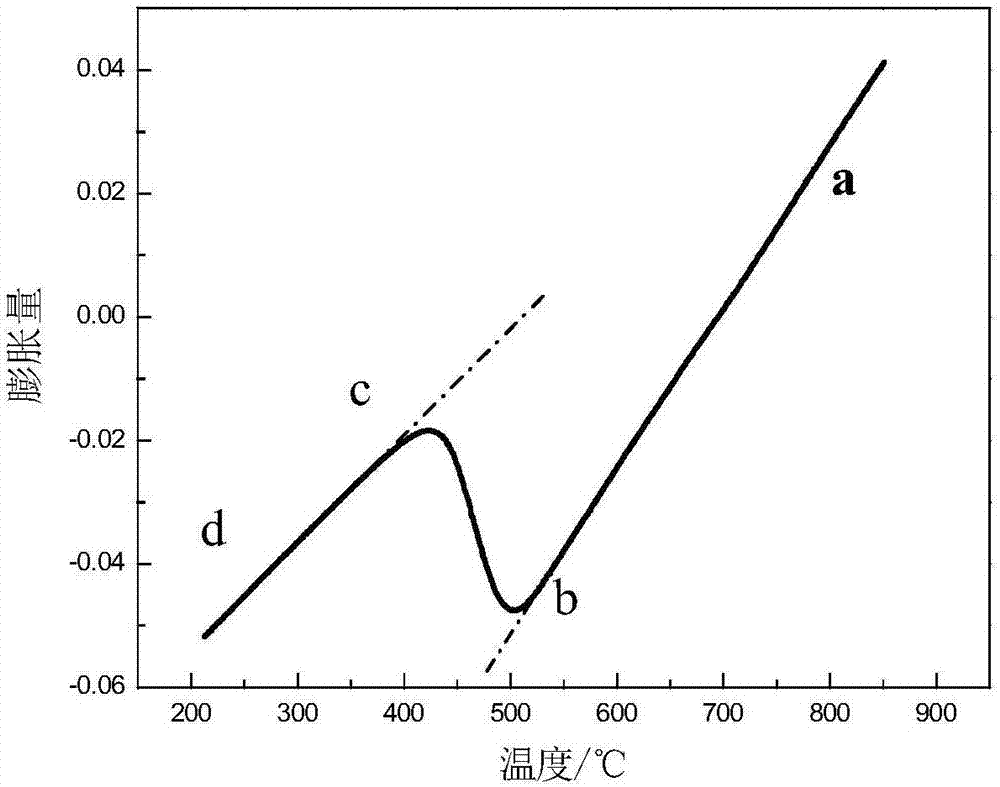

[0017] figure 1 It is a trend diagram of the expansion of niobium-titanium (Ti+Nb about 0.15%) microalloyed high-strength automotive steel with temperature. It can be seen from the figure that the temperature Tb is the transformation start temperature; Tc is the transformation end temperature, and the temperature is at Steel is prone to cracks in this range.

[0018] After comparing and analyzing the low-magnification sample sampling inspection of two continuous casting slabs, the low-magnification rating results are shown in Table 1; the low-magnification photos are as follows: figure 2 and image 3 shown.

[0019] Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com