Composite multi-pipeline tee joint structure assembly

A technology of structural components and multi-pipes, applied in the direction of pipe elements, etc., to achieve the effects of reducing volume, improving strength, and facilitating welding and maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

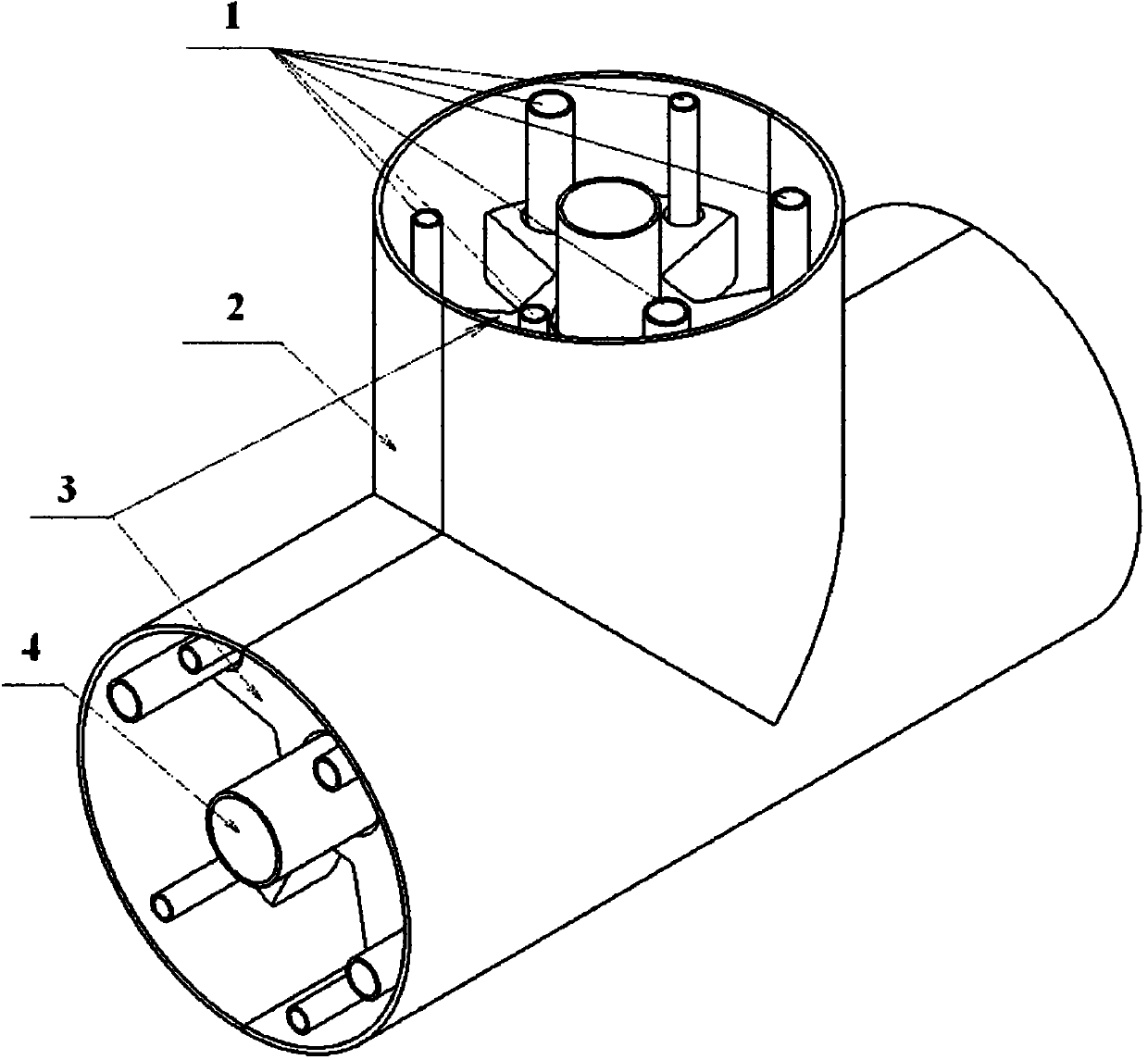

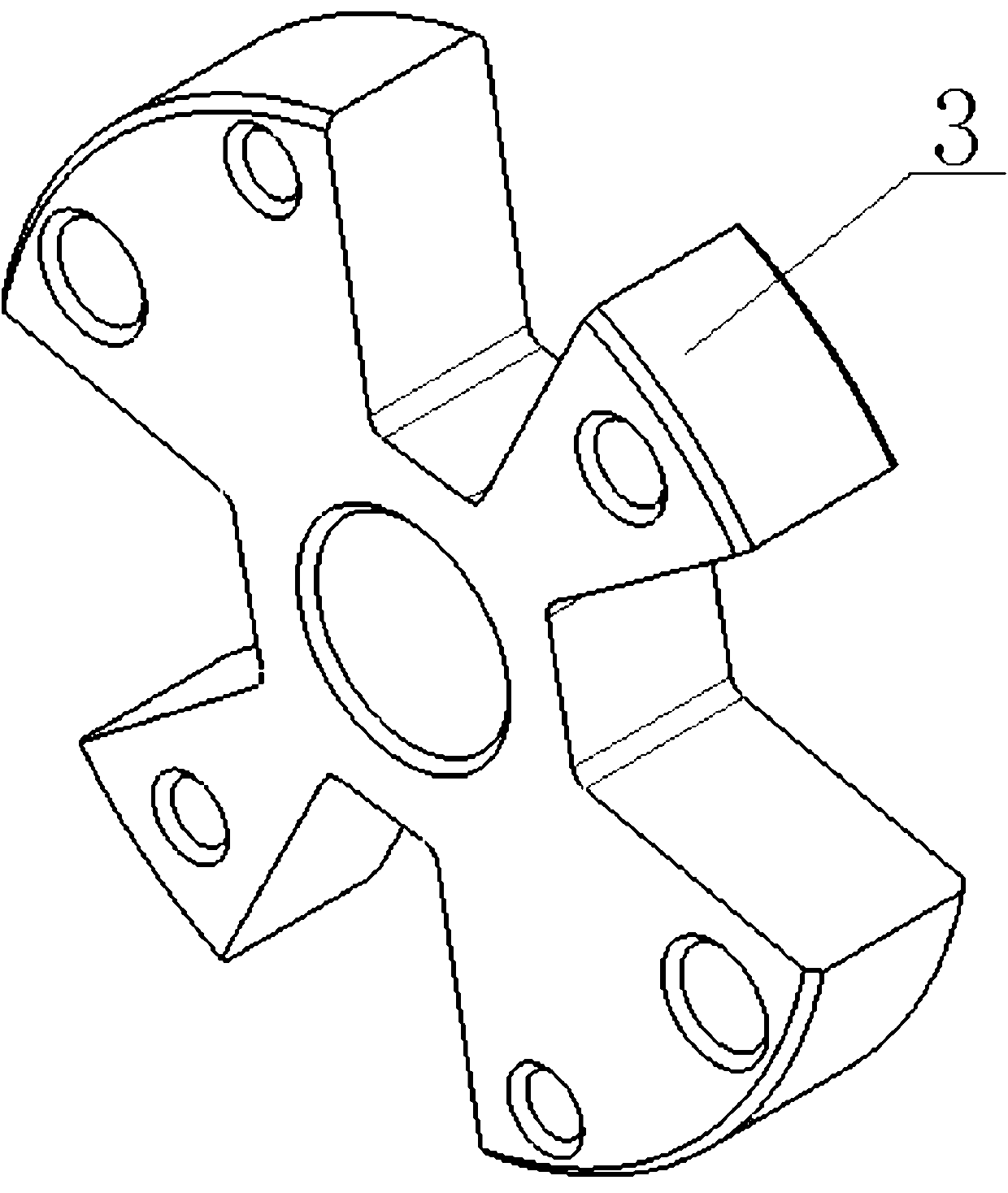

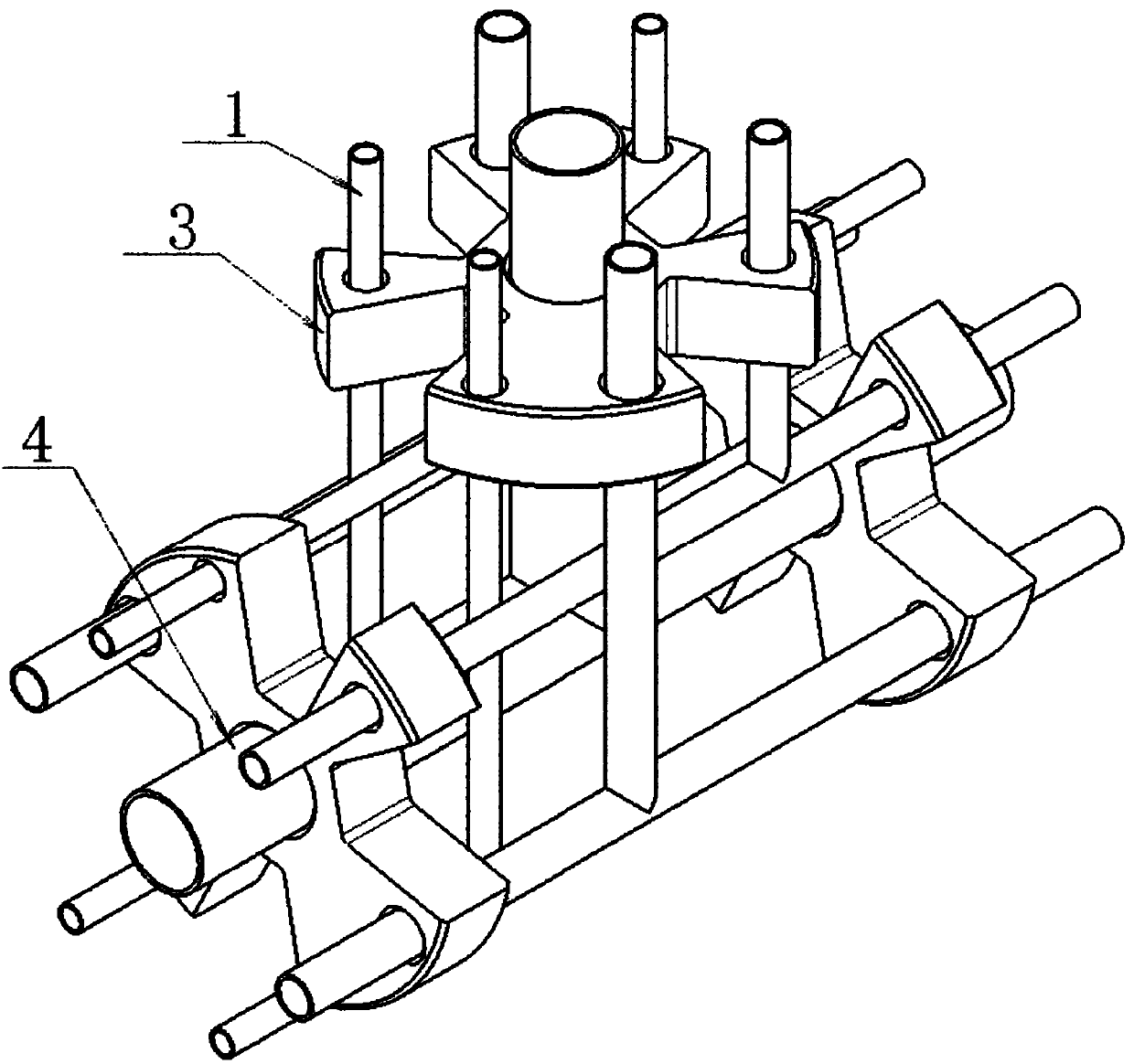

[0016] Such as figure 1 and image 3 As shown, a composite multi-pipe tee structure assembly includes a T-shaped containment pipe 2, and inside the containment pipe are 6 air supply pipes 1, 1 emptying pipe 4 and 3 internal support structures 3. Wherein each air supply pipe 1 and emptying pipe 4 are independently realized three-way, and each air supply pipe 1 and emptying pipe 4 are set on the internal support structure 3, and the internal support structure 3 is a four-leaf windmill blade form. The center and each blade are all provided with through holes, wherein two opposite blades are provided with 2 holes, and the other two blades are provided with a hole. The position of the hole is determined after delicate calculation, which can meet the horizontal and vertical use of the component at the same time, and the internal multiple pipes will not interfere.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com