Full Bore Layered Fracturing Sleeves for Oil and Gas Well Operations

A layered fracturing, full-bore technology, applied to wellbore/well valve devices, wellbore/well components, production fluids, etc. to avoid misoperation, improve reliability, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

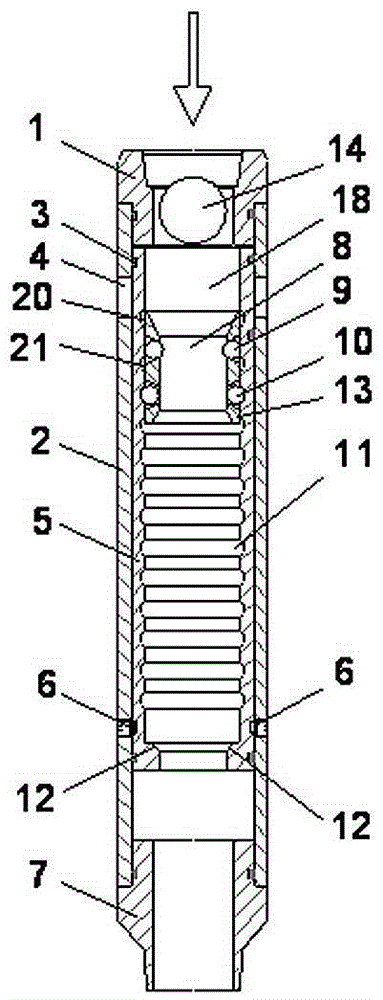

[0038] figure 1 What is shown is a structural form of the full-diameter layered fracturing sliding sleeve used in oil and gas well operations according to the present invention. In the outer cylinder 2 which is respectively connected with the upper joint 1 and the lower joint 7 at the two ends in the axial direction, a working cylinder with an integral structural form inner cylinder 5 structure which can be used for axial sliding is matched. There are shear pins 6 positioned with each other and a limit structure for limiting the sliding distance of the inner cylinder, and the upper part of the outer cylinder 2 is provided with a through guide hole 4 . in:

[0039] a. The inner peripheral surface of the inner cylinder 5 is provided with equally spaced groove structures 11 along the axial direction, and the groove structures 11 are continuous (or discontinuous) grooves arranged along the radial circumference. Cooperating with the groove structures 11, there is a step-type movi...

Embodiment 2

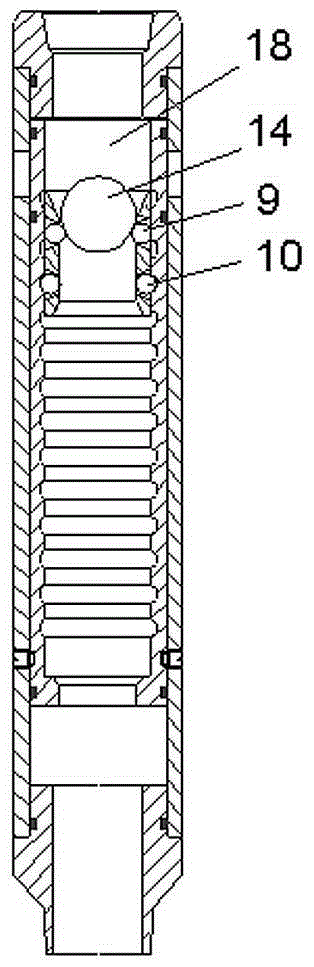

[0051] Figure 8~Figure 10 It is the structure of the overall structural form inner tube 5 structural form working cylinder of another structural form. The difference between it and Embodiment 1 is that the two groups of path switch structures 9, 10 at the axial interval on the step-type moving structure 8 are respectively the front and rear two groups connected to the step-type moving structure 8 through the elastic structure 15. Group claw structure 16,17.

[0052] After throwing the starting ball 14 from the uppermost sliding sleeve, the front claw structure 16 of the step-type moving structure 8 in the uppermost sliding sleeve inner cylinder 5 is located outside the groove structure 11 on the inner peripheral surface of the inner cylinder 5. The rear claw structure 17 is located in the groove structure 11 on the inner peripheral surface of the inner cylinder 5 . In this way, the starting ball 14 drops into and is blocked by the front group claw structure 16 outside the g...

Embodiment 3

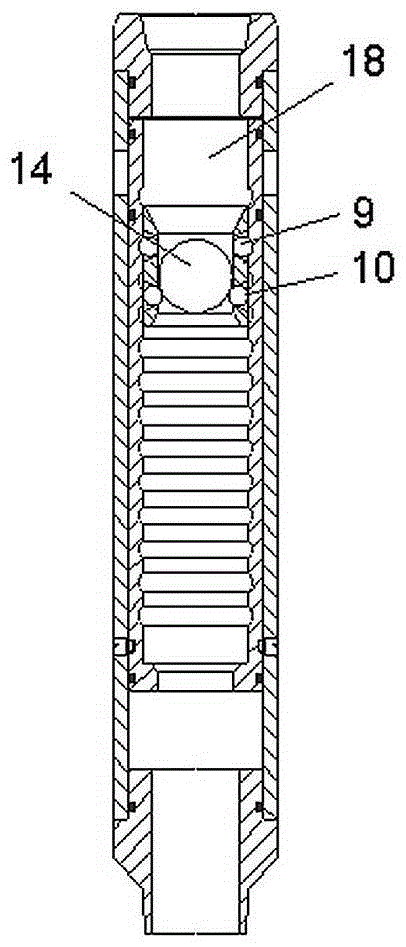

[0057] This example is the structure of a kind of integral structural form inner cylinder 5 structural form working cylinders of combining above-mentioned embodiment 1 and above-mentioned embodiment 2 simultaneously.

[0058] Such as Figure 11 As shown, among the two groups of path switch structures 9 and 10 axially spaced on the step-type moving structure 8, the front group is a rolling structure 23, and the rear group is connected to the step-type moving structure 8 via an elastic structure 15. The elastic claw structure 17.

[0059] After throwing the starting ball 14 from the uppermost sliding sleeve, the rolling structure 23 of the step-type moving structure 8 in the inner cylinder 5 of the uppermost sliding sleeve is located outside the groove structure 11 on the inner peripheral surface of the inner cylinder 5. The claw structure 17 is located in the groove structure 11 on the inner peripheral surface of the inner cylinder 5 . In this way, the starting ball 14 is dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com