Mechanical drive two-way self-locking device

A mechanical transmission, two-way self-locking technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of safety accidents, difficult to control, fluctuations in the descending speed of heavy objects, etc., to improve the safety factor, simple structure, and free operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

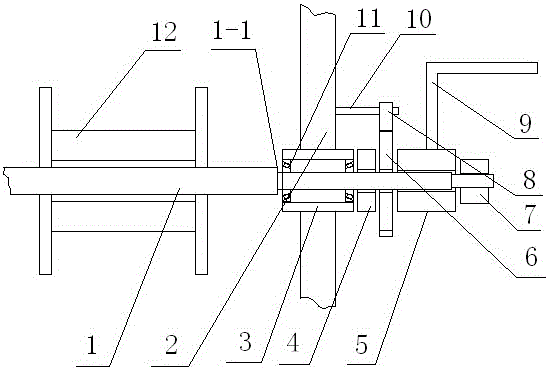

[0020] Such as figure 1 As shown, the mechanical transmission two-way self-locking device of the present invention includes a support frame body 2, a transmission shaft 1, a ratchet 6 and a pawl 8 installed on the support frame body 2, and the pawl 8 can be installed on the support frame body through a rotating shaft 10 2, the pawl 8 is engaged with the ratchet 6 to realize the braking of the ratchet 6. The transmission shaft 1 is connected to the support frame body 2 through the seat cover 3, and the seat cover 3 can be a casing structure welded to the support frame body 2; Thrust bearing 11 is worn and connected with bearing seat, and it is more portable and flexible to operate. The ratchet 6 is movably connected with the transmission shaft 1 and can rotate freely on the transmission shaft 1. The transmission shaft 1 is provided with a limiting structure 1-1 and a friction assembly, wherein the limiting structure 1-1 is arranged on the load side of the seat cover 3 to prev...

Embodiment 2

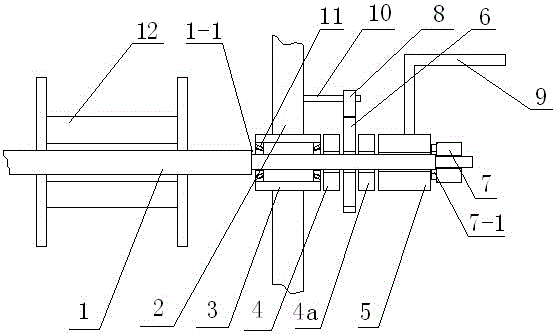

[0023] see figure 2 , as a further improvement, in the mechanical transmission two-way self-locking device of this embodiment, the number of the friction damping parts is 2, and the two friction damping parts 4, 4a are respectively arranged on both sides of the ratchet, which can increase Self-locking torque, using friction damping parts 4 and 4a with an outer diameter of 60mm, the maximum self-locking torque can reach more than 1000kg. When it is necessary to increase the load torque, just increase the effective cross-sectional area of friction damping parts 4 and 4a appropriately. . The actuating screw sleeve 5 can be connected with the transmission shaft 1 through multiple threads, which is convenient to increase the lead of the connecting thread, increase the transmission of the rotational torque of the actuating screw sleeve 5, and make the reverse rotation operation more sensitive. The compression nut 7 is preferably connected to the transmission shaft 1 through a fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com