Measuring method and device aiming at axial play of four-row tapered roller bearing

A technology for tapered roller bearings and measuring devices, which is applied in the direction of measuring devices and instruments, can solve the problems of complex axial clearance measurement process, high labor intensity, and poor measurement accuracy of four-row tapered roller bearings, and improve the measurement accuracy. Efficiency and measurement accuracy, simple measurement method, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

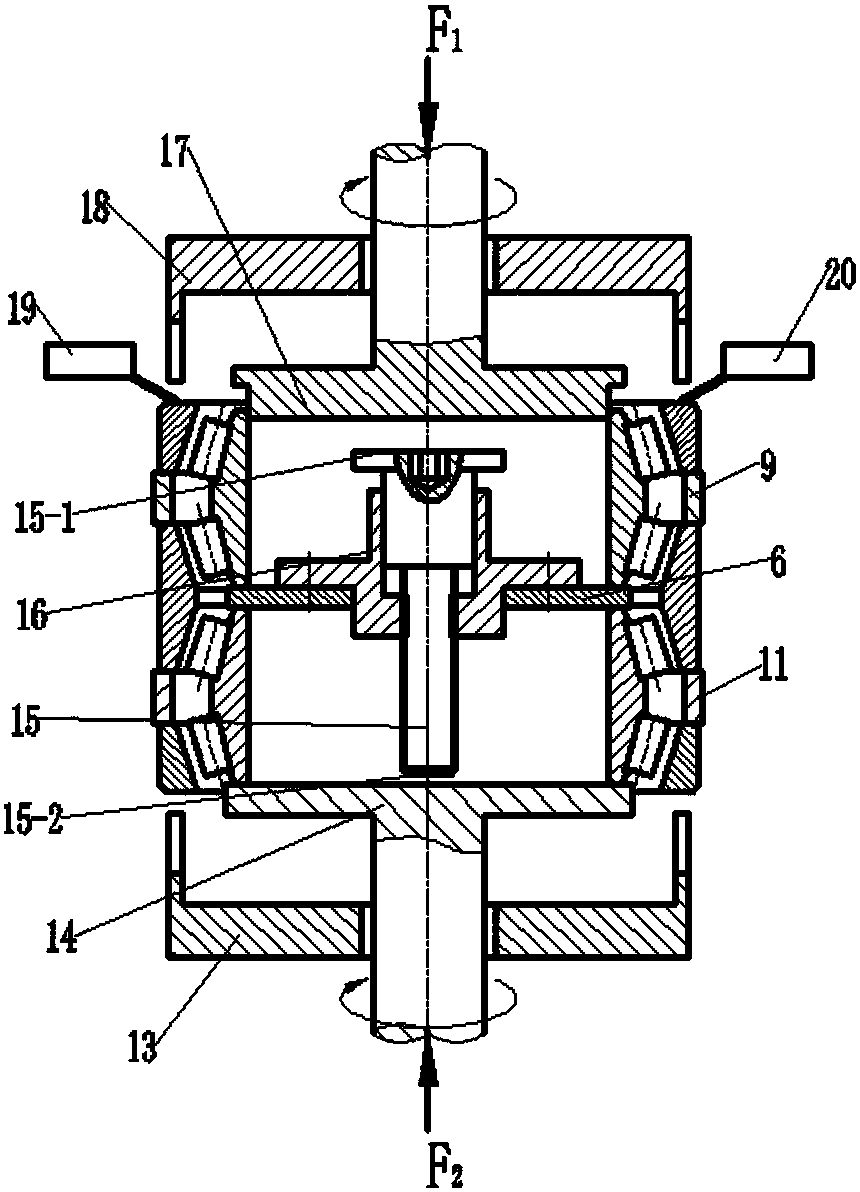

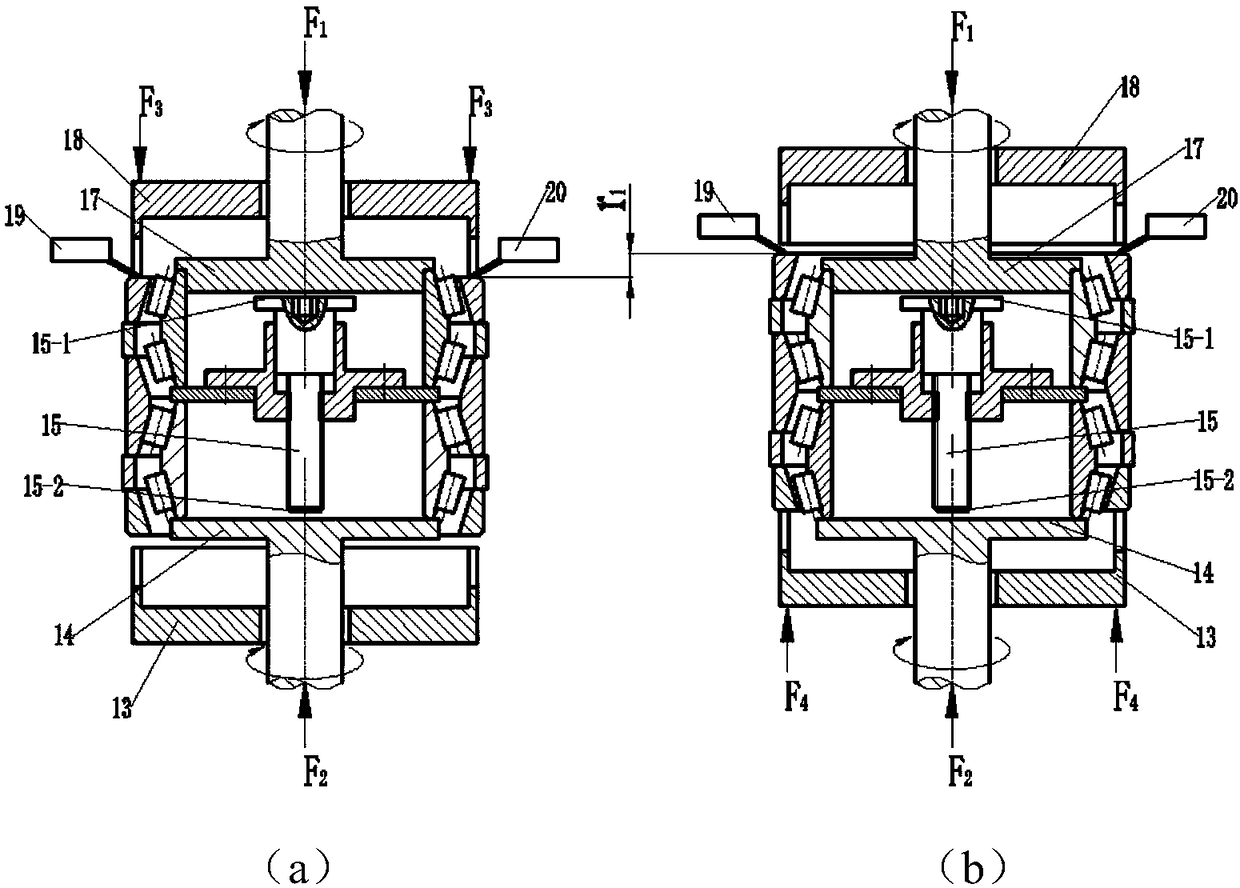

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0031] A measuring device for the axial clearance of a four-row tapered roller bearing, the measuring device includes an adjusting device, an inner ring clamping device, an outer ring loading device and a clearance measuring device.

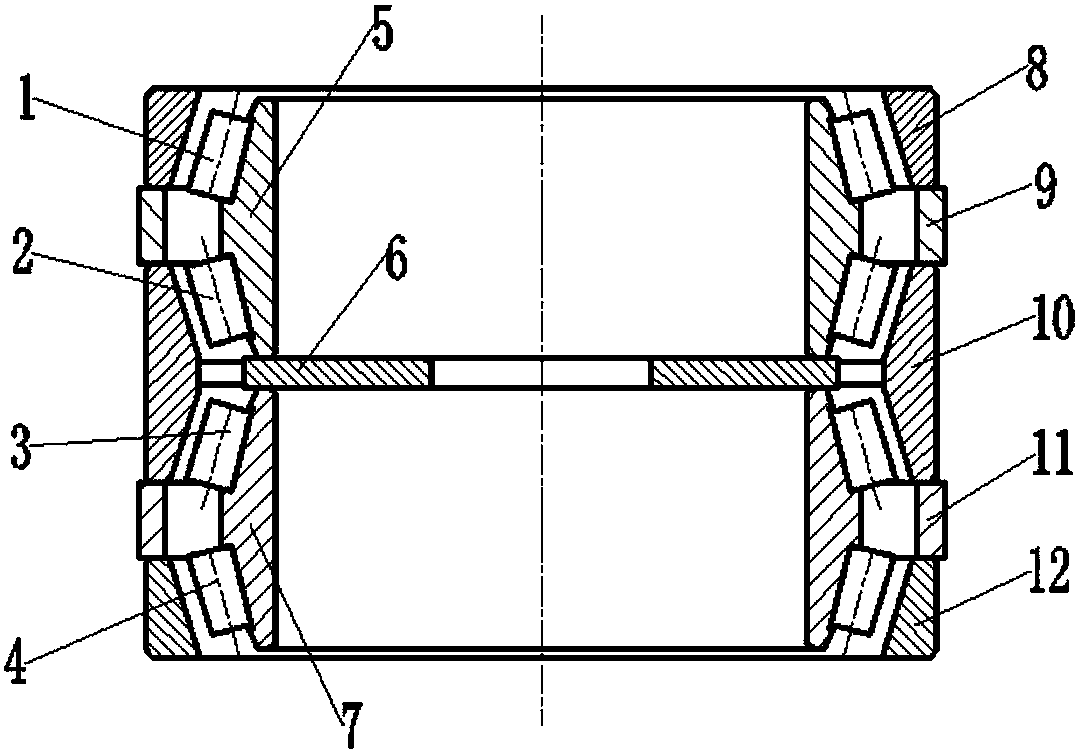

[0032] The adjustment device is centered on the inner spacer ring 6 and has a symmetrical structure up and down. The upper inner ring 5 and the lower inner ring 7 form a hollow structure. The inner spacer 6 is located between the upper inner ring 5 and the lower inner ring 7. A round hole is opened in the center of the inner spacer 6. The diameter of the round hole of the inner spacer 6 is Smaller than the inner diameters of the upper inner ring 5 and the lower inner ring 7 . The first row of rollers 1 and the second row of rollers 2 are installed on the outside of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com