Optical measurement instrument and measurement method using the same

A technology of optical measurement and measurement method, which is applied in the direction of measuring instruments, active optical measuring devices, instruments, etc., can solve the problems of high labor intensity of workers, influence on construction progress, and inconvenient use, so as to reduce labor intensity of workers and improve construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

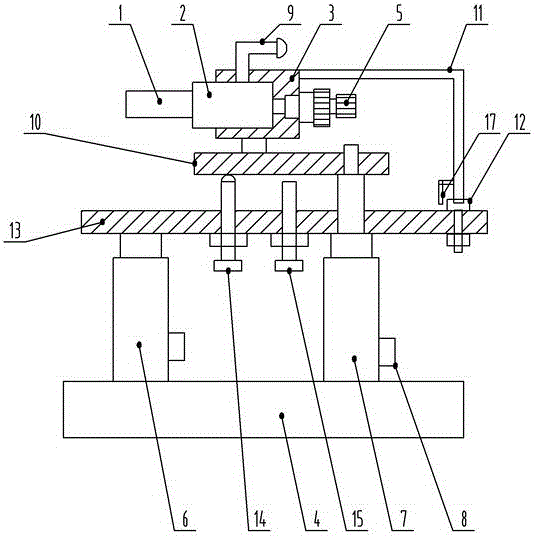

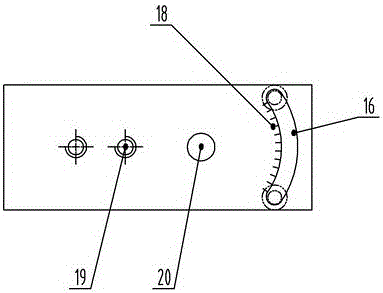

[0025] Embodiment one: see Figure 1-2 , in the figure, the present invention is used for the instrument of optical measurement, comprises laser pointing beam expander 1 and host machine 2, and support 3, base 4, micrometer 5, lift adjustment column I6 and II7 and lift adjustment motor 8. Wherein the support is located directly above the base, the rear end of the main engine is horizontally slid and fitted in the blind hole at the front end of the support, and a tightening handle 9 is provided between the rear end of the main engine and the radial direction of the support for fixed positioning. The micrometer screw head of the micrometer is inserted into the through hole set at the rear end of the support, and is pushed against the rear end surface of the host, and fixed with a set screw; by turning the knob on the micrometer, the micrometer screw on the micrometer moves The host and the laser pointing beam expander move longitudinally to adjust and determine the longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com