Multifunctional sniper rifle buttstock

A sniper rifle and multi-functional technology, which is applied in the field of conventional weapons and sniper rifle stocks, can solve the problems of fixed structure, poor versatility, and inability to adjust the position of the cheek plate, so as to achieve the effect of improving versatility and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

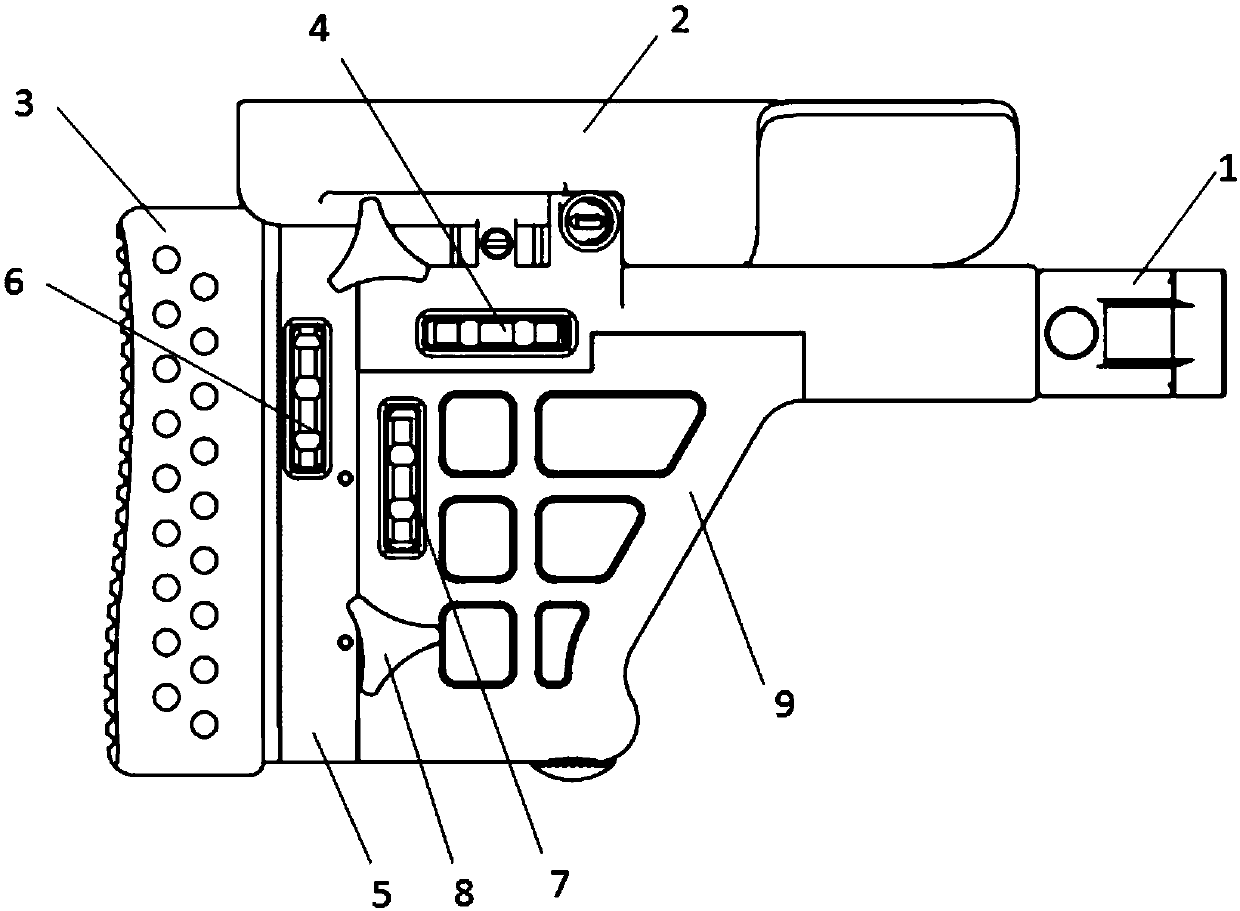

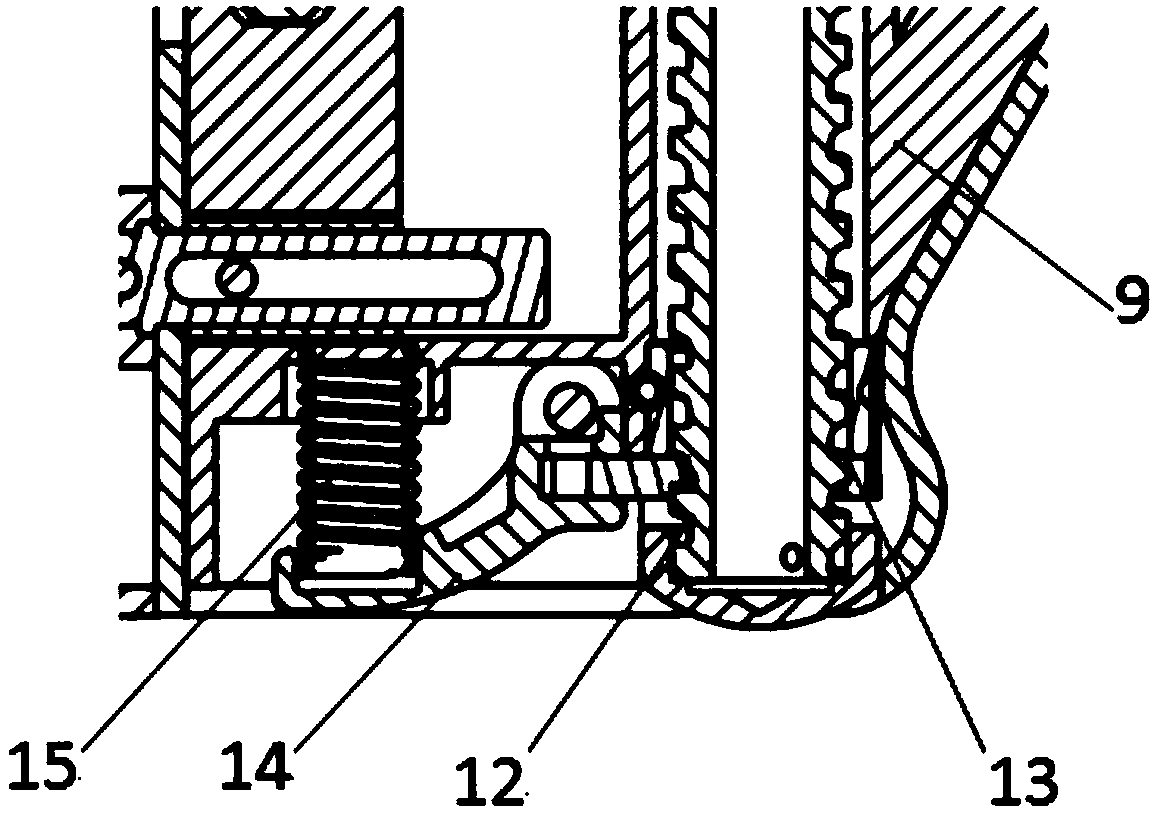

[0024] Embodiment 1: see figure 1 —— Figure 4 .

[0025] A multi-functional sniper rifle stock of the present invention comprises a stock main body 9, a joint part 1 coaxially connected with the front end of the stock main body 9, a cheek plate 2 located at the upper end of the stock main body 9, and a rear part of the stock main body 9 The shoulder support 3 at the end is characterized in that: the bottom of the cheek board 2 is connected with a screw rod 10 perpendicular to the cheek board, and the cheek board screw 10 is connected with the cheek board adjustment handwheel 4 with a screw sleeve in its circumferential direction. Teething, the cheek plate adjustment handwheel position 4 is fixedly connected with the gunstock main body 9 and is located at an opening of the gunstock main body 9, and the shoulder rest 3 is locked on the shoulder rest height adjustment handwheel 6 through the shoulder rest. On the part 5, the shoulder rest height adjustment handwheel 6 is locat...

Embodiment 2

[0027] Example 2: see figure 1 —— Figure 5 .

[0028] On the basis of the above-mentioned embodiments, a second embodiment is proposed, which is characterized in that: the front end of the joint part 1 is a connecting part 17, and the rear end is a rotating part 21, and one end of the rotating part 21 is connected with the gunstock main body 9, and the other end is It is connected with the connection part 17, and the characteristic is that the connection mode of the connection part 17 and the rotating part 21 is connected through the rotating shaft 18 on one side, and connected with the L-shaped lock buckle 20 with spring on the rotating part 21 on the other side. The positioning boss 19 on the upper part is engaged. In order to cope with a variety of combat environments, it is often necessary to fold the gun stock to shorten the length of the gun. At this time, just press the L-shaped lock buckle 20 with the spring, and the L-shaped lock buckle 20 with the spring and the p...

Embodiment 3

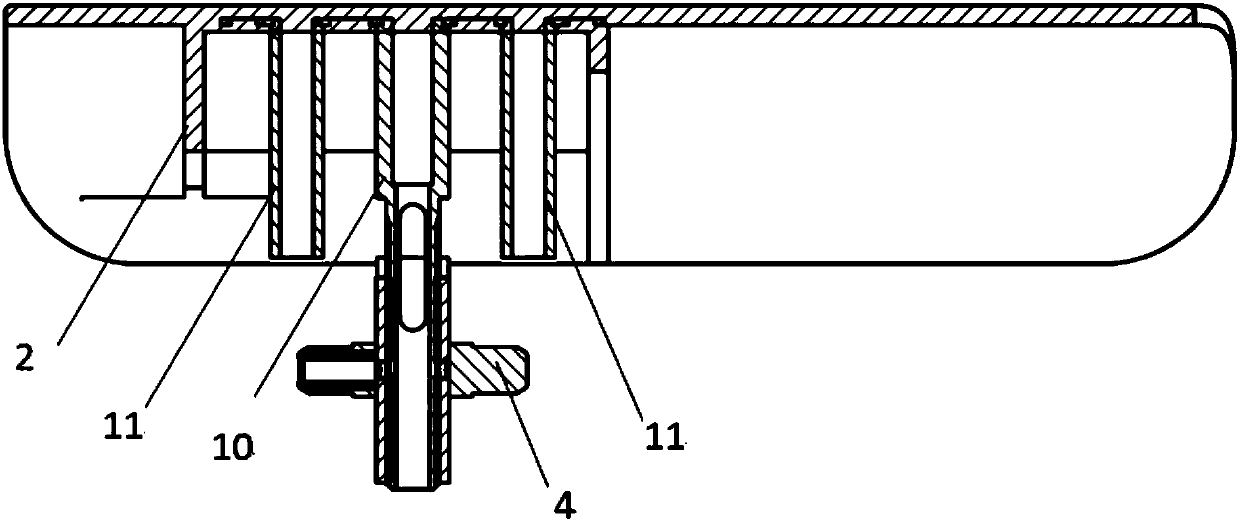

[0029] Embodiment 3: see figure 1 —— Figure 5 .

[0030]On the basis of the above embodiments, a third embodiment is proposed, which is characterized in that: a cheek board guide post 11 is arranged between the cheek board 2 and the gun stock main body 9 . When adjusting the cheek board 2 up and down, the lateral movement of the cheek board 2 can be effectively avoided through the guidance of the cheek board guide column 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com