Suspension device, control method thereof, vehicle and engineering machinery

A control method and suspension technology, applied in vehicle components, suspension, elastic suspension, etc., can solve the problems of not indicating the cab and frame, affecting the vibration comfort of the cab, driving safety risks, etc., to improve the vibration The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

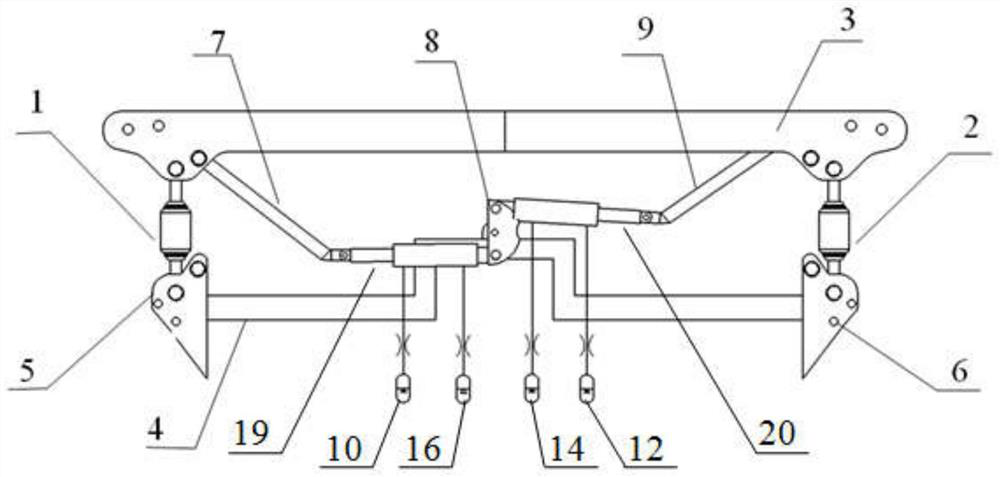

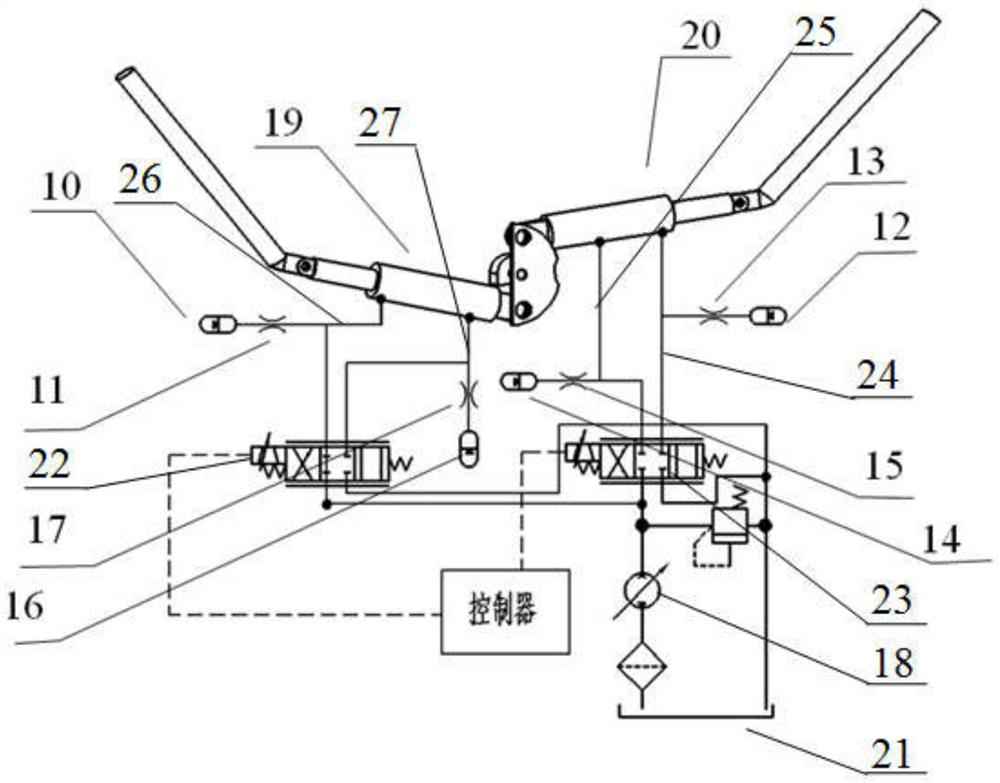

[0044] Such as figure 1 and 2 As shown, the present embodiment provides a suspension device, which includes an upper beam 3, a lower beam 4, a Watt linkage mechanism, an autonomous attitude adjustment system and a vibration damping system.

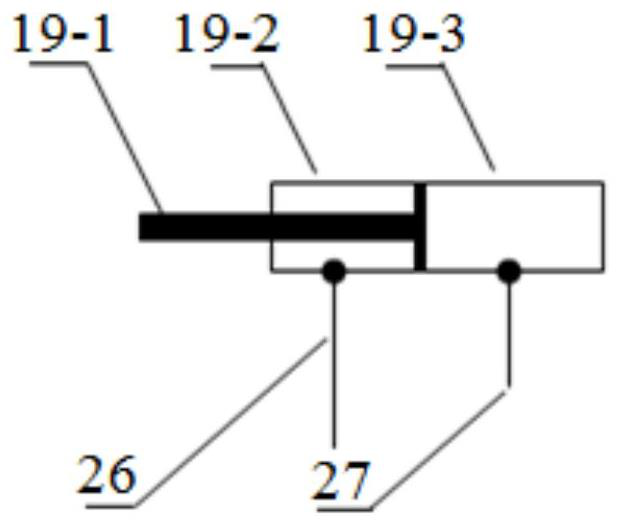

[0045] Such as figure 1 As shown, the Watt linkage mechanism is used to control the left and right swing of the cab, including connecting rod A 7, hydraulic cylinder A19, intermediate connecting rod 8, hydraulic cylinder B 20 and connecting rod B 9, and one end of connecting rod A 7 is connected to the upper beam 3. The other end is connected to the hydraulic cylinder A19, one end of the connecting rod B9 is connected to the upper beam 3, and the other end is connected to the hydraulic cylinder B20, the hydraulic cylinder A19 and the hydraulic cylinder B20 are respectively connected to the upper and lower ends of the middle connecting rod 8, and the middle The connecting rod 8 is connected with the lower beam 4 . The two ends of the low...

Embodiment 2

[0050] This embodiment provides a method for controlling a suspension device, including:

[0051] (1) Cab left and right swing control

[0052] When the vehicle is driving on an uneven road surface, tilting or turning into a forward driving moment, the cab will roll, laterally shift or sway with the left and right tilt of the chassis. The characteristics of the Watt linkage mechanism can reduce the above motions to The vertical movement of the cab relative to the chassis and the rotation around the installation point of the middle link, and due to the self-locking effect of the Watt linkage mechanism, the rotation of the cab around the installation point of the middle link will be restricted, so that the cab can follow the left and right of the chassis. Swing is under control. Among them, the damping and stiffness of hydraulic cylinder A and hydraulic cylinder B are more than twice the damping and stiffness of air spring A and air spring B, otherwise the elasticity is too sma...

Embodiment 3

[0060] This embodiment provides a vehicle configured with the suspension device described in Embodiment 1, and the suspension device is controlled by the control method described in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com