Steel cable guide mechanism and building curtain wall fixing device consisting of steel cable guide mechanism

A technology of guiding mechanism and steel cable, applied in the direction of buildings, building components, building structures, etc., can solve the problems of reducing the strength of the main structure, the reserved aperture should not be too large, and occupy a lot of space, so as to improve the service life and reduce the Wear and improve the effect of stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

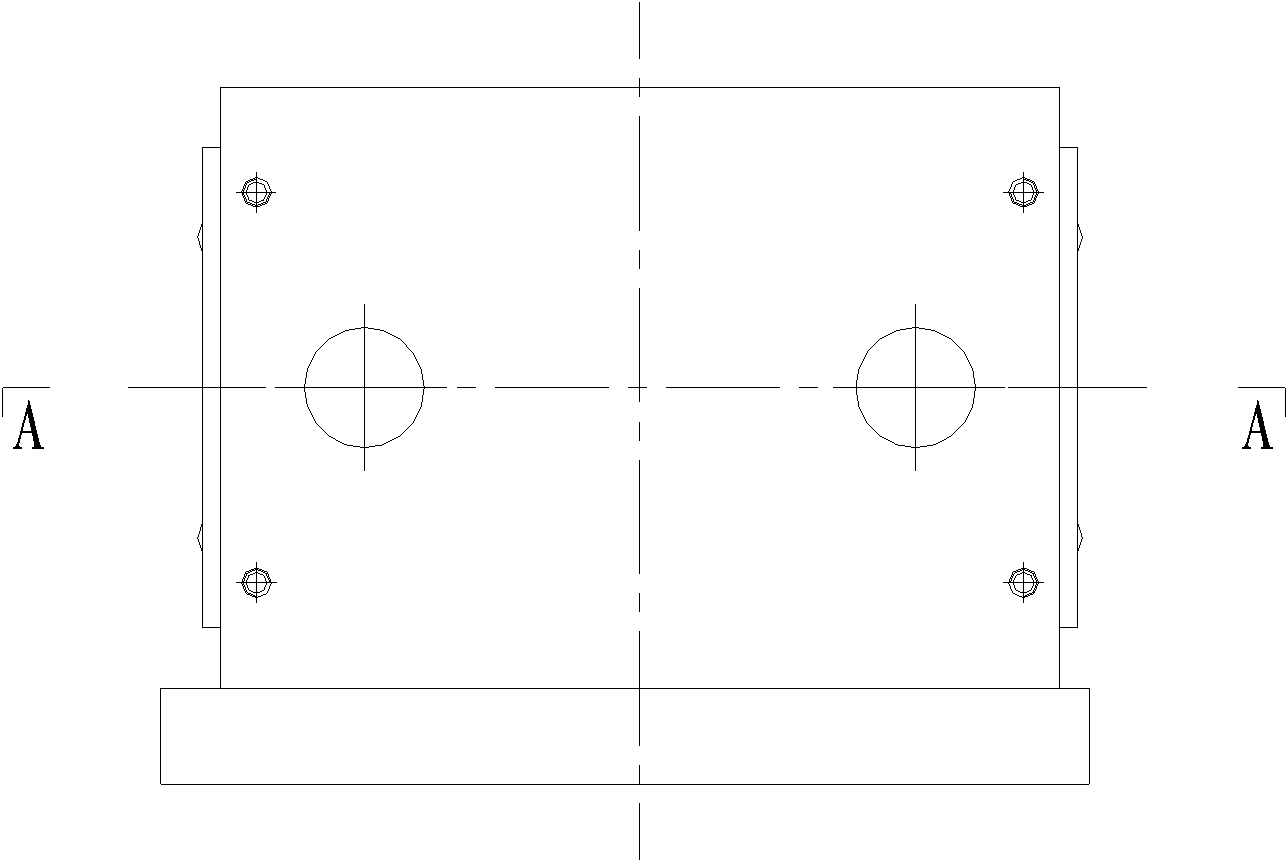

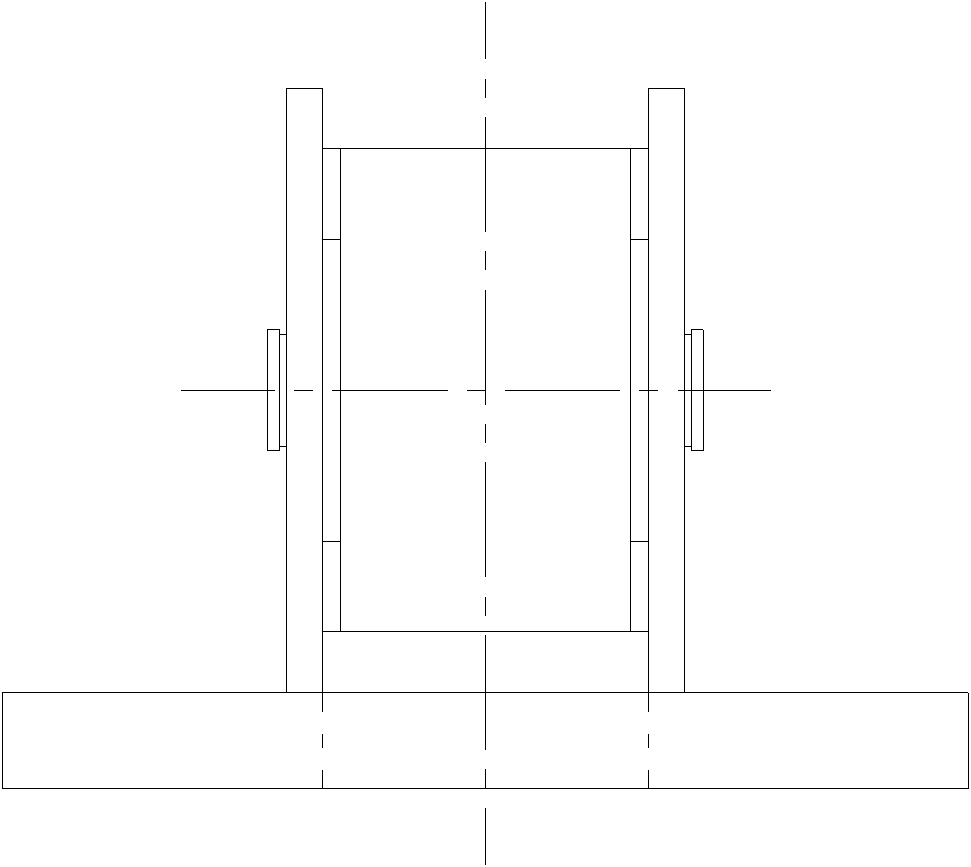

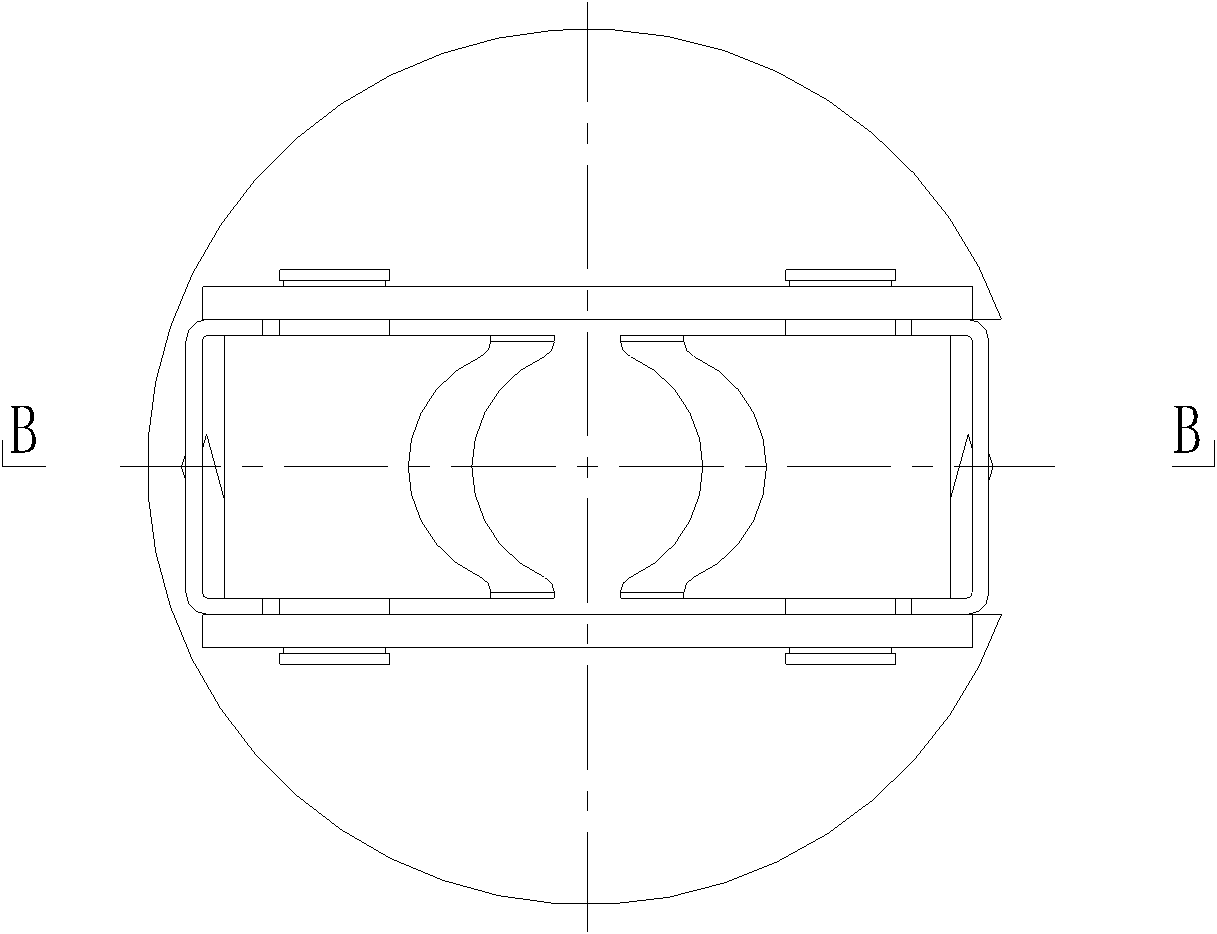

[0054] like Figure 1 to Figure 9 As shown, the cable guiding mechanism of the present invention includes a fixed seat 1 provided with an open slot 10, a guide wheel 2 arranged in the open slot 10, the guide wheel 2 and the fixed seat 1 are rotationally connected, and the guide wheel 2 is two . In this embodiment, the fixing seat is a split weldment structure, which is composed of two side plates 11 arranged at both ends of the guide wheel 2 and a bottom plate 12 for fixing the two side plates 11 . The bottom plate 12 is provided with a U-shaped groove 120 , and the gap between the U-shaped groove 120 and the two side plates 11 constitutes the aforementioned open groove 10 . The guide wheel 2 is provided with a central hole 20 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com