Spring

A technology of outer ring and inner ring, which is applied in the direction of spring/shock absorber, coil spring, mechanical equipment, etc., can solve the problems that affect the life of the clutch, and the aging of the buffer rubber sleeve, so as to increase the life, reduce the material and save the cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

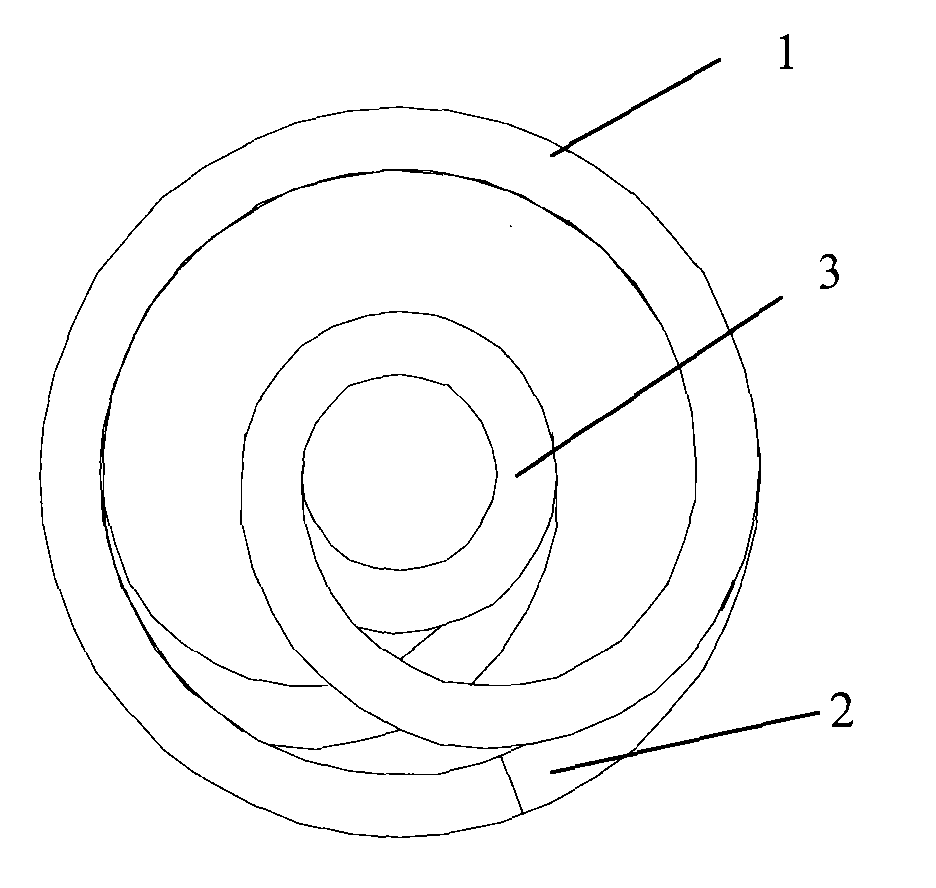

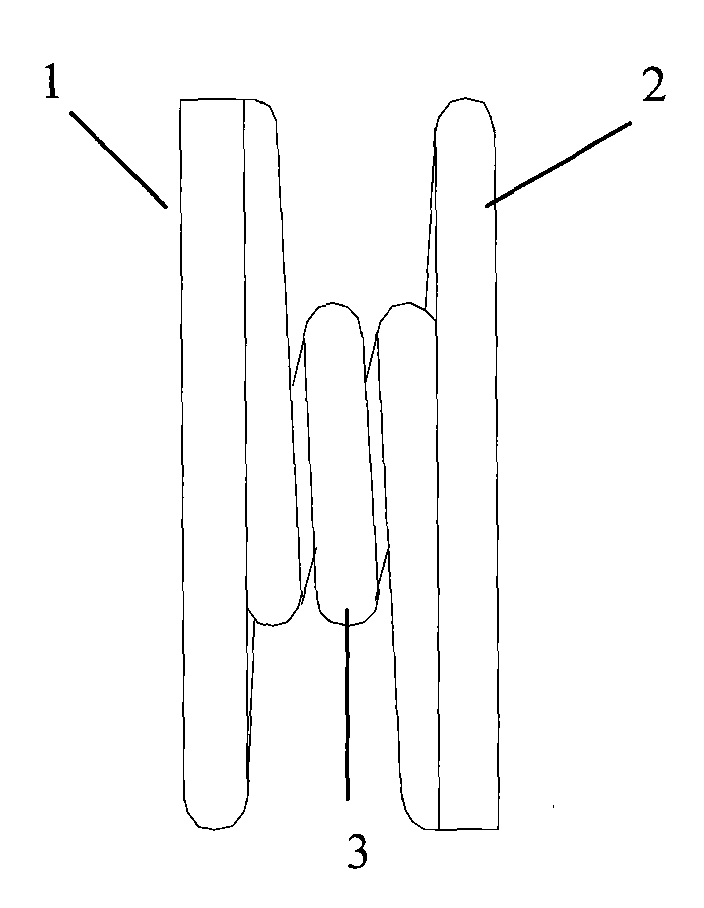

[0017] Such as figure 1 A kind of spring shown, this spring is wound with steel wire, comprises spring outer ring 1 and 2, spring inner ring 3, wherein, spring outer ring is larger than spring inner ring caliber. The overall shape of the spring is that two tower-shaped springs are connected by small ends, such as figure 2 shown.

[0018] The spring of this shape is equivalent to the combination of two pagoda springs with small heads facing each other, but the stroke space can be greatly reduced. Compared with the combination of two pagoda springs with small heads facing each other, the material is reduced and the cost is saved. Moreover, the spring of this shape has the characteristics of shock absorption and not easily deformed. It is suitable for any mechanical structure that requires tension damping, especially in structures with limited space. The shock-absorbing buffer spring replaces the buffer rubber sleeve in the motorcycle clutch, can enhance the service life of t...

Embodiment 2

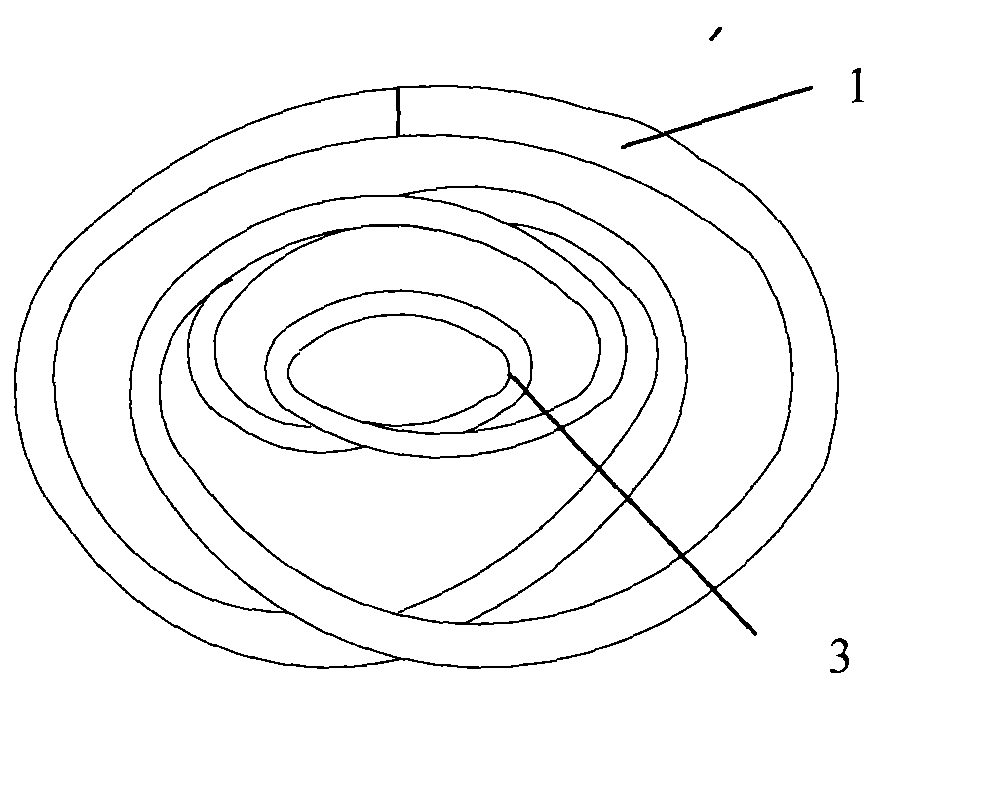

[0020] Such as image 3 As shown, the shock absorbing buffer spring is elliptical in plan view.

Embodiment 3

[0022] Such as Figure 4 As shown, the shock absorbing buffer spring is diamond-shaped in plan view.

[0023] When the spring is working, the outer ring is fixed in a circular hole, and the inner ring is fixed on a cylinder. When there is a lateral displacement between the circular hole and the cylinder, there will also be a dislocation between the inner ring and the outer ring of the spring. Due to the composition of the spring The rigidity of the steel wire itself plays the role of buffering and shock absorption, which is to use the misalignment of the inner and outer rings of the spring to buffer the displacement of the external force of shock absorption. A spring steel wire is used to wind the inner ring and the outer ring, and the misalignment of the inner ring and the outer ring produces a buffering effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com