White light LED packaging structure and packaging method thereof

A technology of LED packaging and LED chips, applied in the direction of electrical components, electrical solid devices, circuits, etc., to achieve the effects of easy process, high conversion efficiency, and small difference in refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

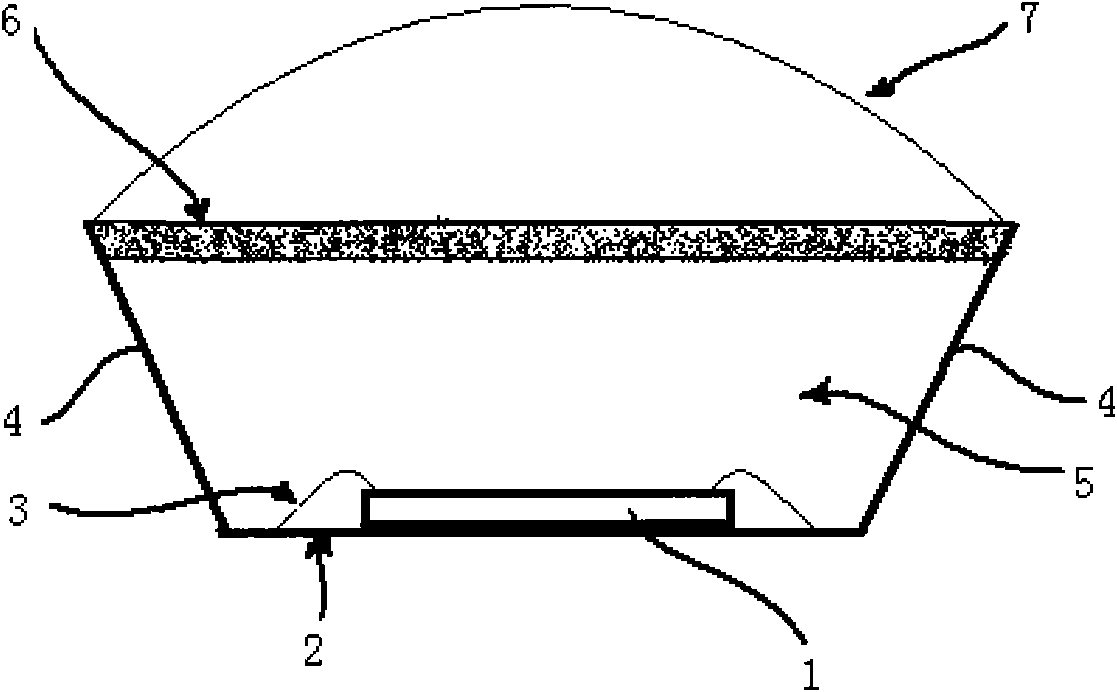

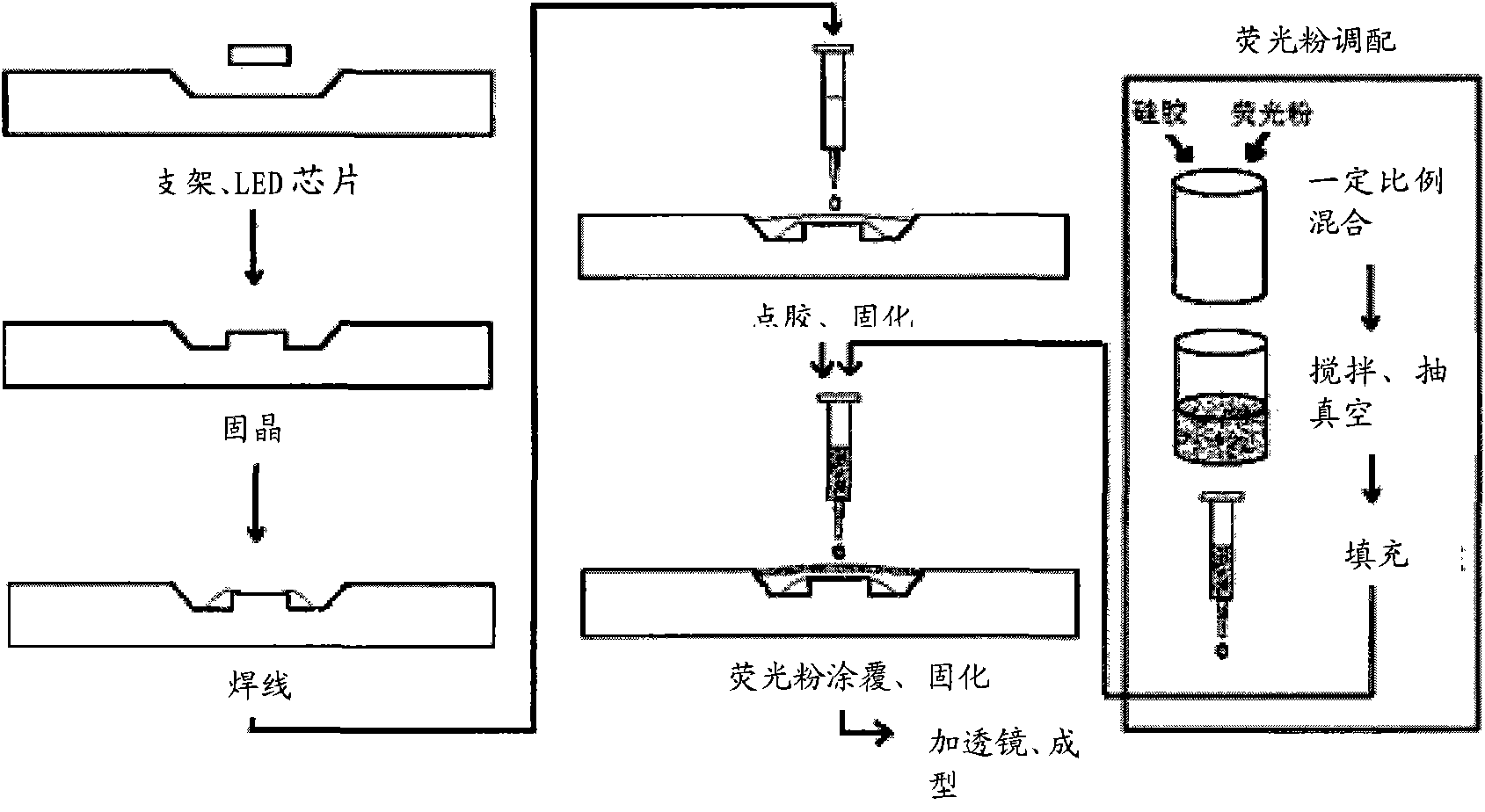

[0034] like figure 1 , figure 2 and image 3As shown in the figure, put a certain amount of silver glue on the cup and bowl of the bracket, put the high-power sapphire substrate GaN blue LED chip 1 on the silver glue of the bracket 2, and perform thermal hardening baking to cure the silver glue. , to fix the LED chip 1 on the bracket 2; weld a gold wire on the electrode of the LED chip 1 to complete the electrical connection with the bracket 2; It is directly coated on the LED chip 1, and after curing, the prepared phosphor is coated on the cured thermal insulation transparent material layer 5 by dispensing or gluing, and cured by baking; Upper peripheral optical components such as lens structures 7 .

Embodiment 2

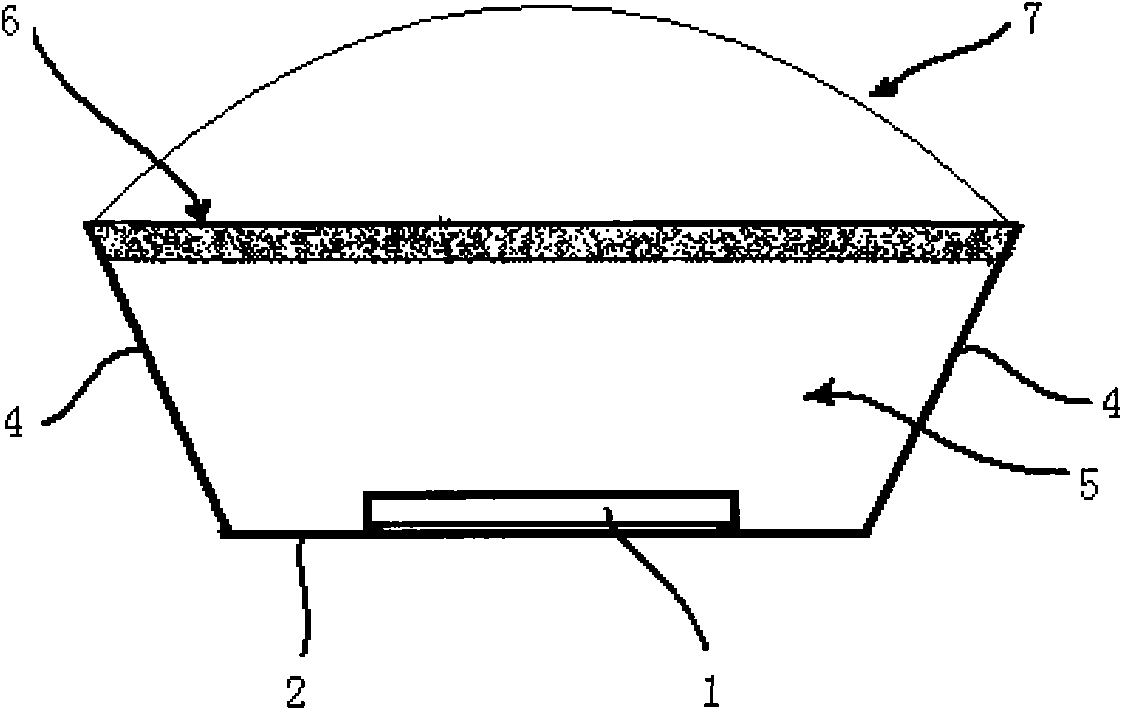

[0036] For the packaged bracket 2 is a plane bracket, such as Figure 4 shown. Then directly coat a certain amount of silica gel on the surface of the LED chip 1 that has been fixed on the bracket 2. Due to the surface tension of the silica gel, it can form an approximate spherical surface. After the silica gel is no longer diffused, put it in the oven and bake at 150°C. After 30 minutes of curing, a heat insulating material layer is formed; the phosphor layer is also coated by the same principle using the same method.

Embodiment 3

[0038] like Figure 5 and Image 6 As shown in the figure, the white LED is encapsulated by the thermal isolation method, and the upper surface of the cured silica gel is coated with two-layer phosphor layers in turn, which are the red phosphor layer 61 and the YAG phosphor layer 62 respectively. Using the coating method of thermally isolated double-layer phosphor layer, the obtained white light LED has a higher color rendering index (Ra can reach more than 90), better light color stability and better heat dissipation effect than the existing white light LED. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com