LED (light emitting diode) packaged based on zinc oxide-bismuth oxide composite ceramic substrate and preparation method thereof

A technology of composite ceramics and base piezoceramics, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of easy breakdown of PN junctions, and achieve simple electrical circuits, strong resistance to instantaneous current inrush, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

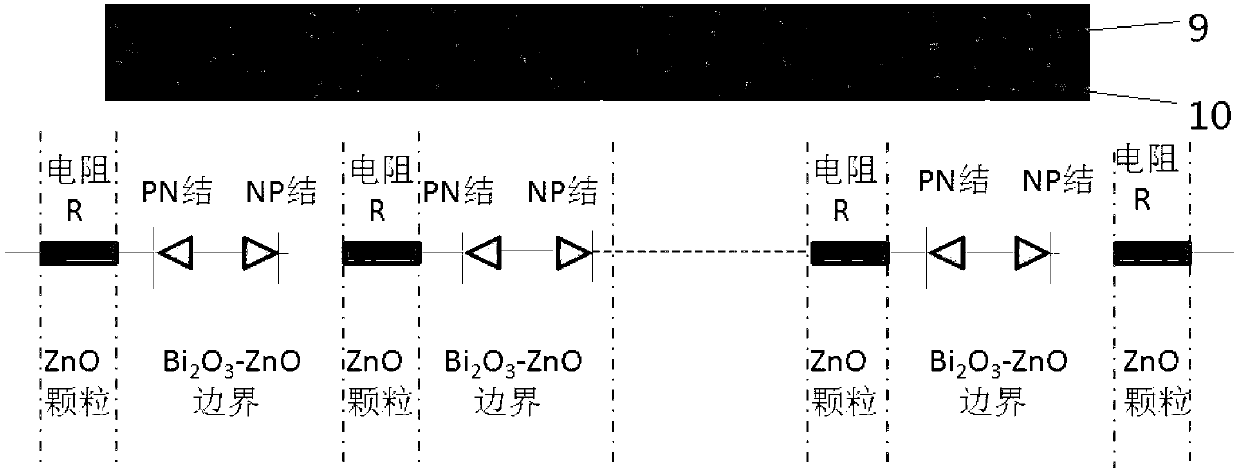

Method used

Image

Examples

Embodiment 1

[0060] Example 1 Weighing an appropriate amount of ZnO and Bi 2 o 3 The powder is stirred and mixed evenly according to the molar ratio of 98%: 2%. After ball milling and isostatic pressing, the green body is made and sintered in a nitrogen atmosphere furnace at 1100-1250 oC. Among them, the isostatic pressure is 50Mpa, and the holding time is 2 hours under normal pressure and high temperature sintering. When the temperature drops below 300 oC, the ceramic substrate with a diameter of 5 cm and a thickness of 1.2 mm is obtained. The LED is prepared by the following process:

[0061] 1. The surface of the ceramic sheet is polished.

[0062] 2. Clean the surface with alcohol and acetone, rinse with deionized water and bake at 200oC for 10-60 minutes.

[0063] 3. Make copper / silver film on the front and back surfaces of the ceramic by plasma sputtering; the thickness of the copper / silver double layer film is 2μm and 200nm respectively.

[0064] 4. Etch the double-layer film el...

Embodiment 2

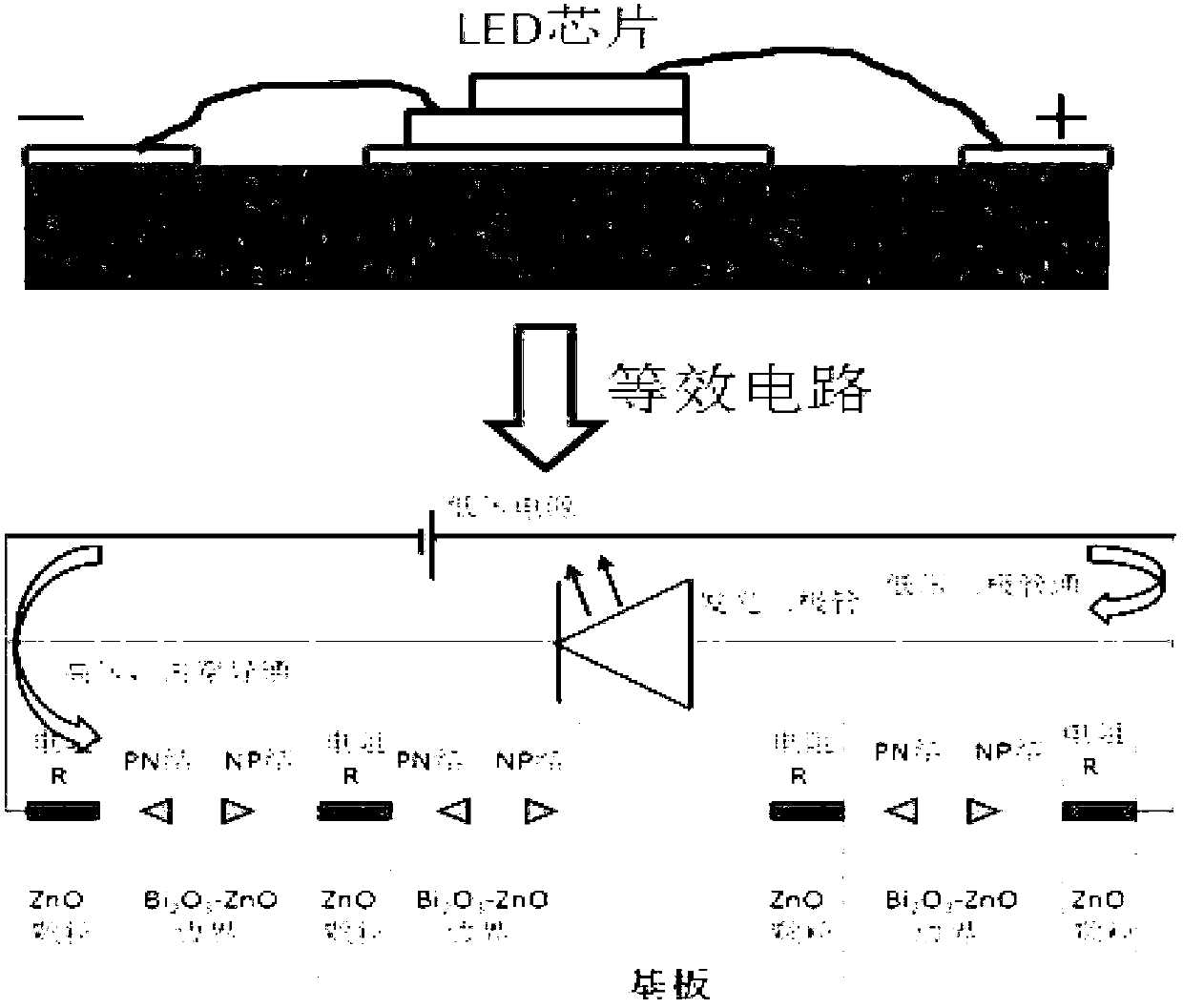

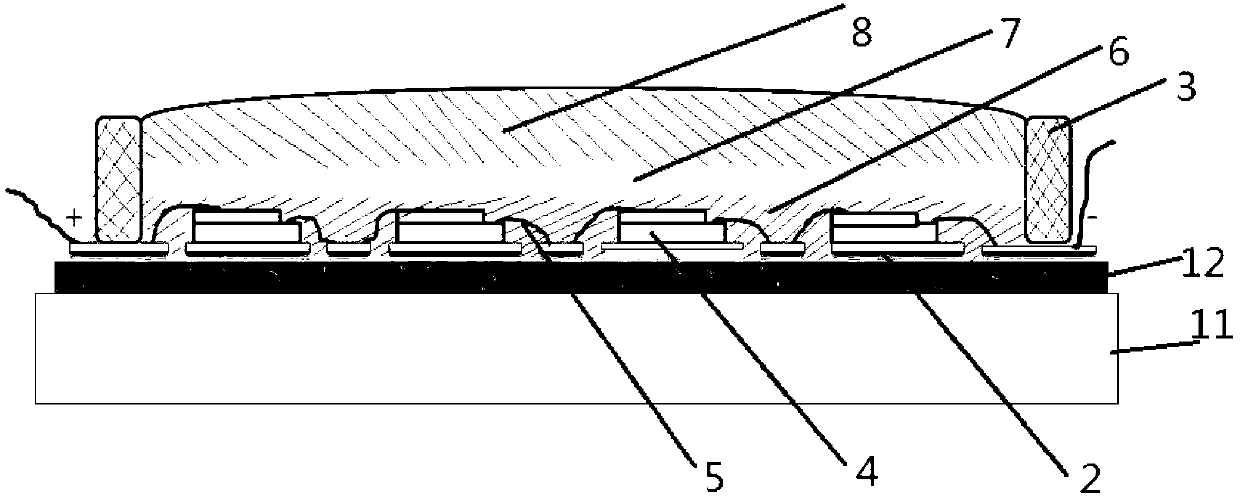

[0072] combine Figure 4 illustrate

[0073] 1. Prepare Bi according to the same process as in Example 1 2 o 3 Doped ZnO ceramic discs.

[0074] 2. Put the above ceramic wafer into the target splint of the magnetron sputtering chamber.

[0075] 3. Put the metal aluminum substrate 11 in the substrate tray of the magnetron sputtering chamber.

[0076] 4. Turn on magnetron sputtering to obtain 10 μm thick Bi on the metal aluminum substrate 2 o 3 doped ZnO ceramic film 12 .

[0077] 5. Sputtering the copper / silver double-layer film electrode 2 on the above-mentioned substrate.

[0078] 6. Prepare an LED modular light source array according to step 4 to step 10 of embodiment 1. The schematic diagram of the overall effect of the section of the LED light source module is as follows: Figure 4 .

Embodiment 3

[0080] combine Figure 5 illustrate

[0081] 1. A large aluminum substrate covered with a ZnO varistor ceramic film and a metallized film was prepared according to the same process as step 1 to step 5 of Example 2.

[0082] 2. According to the same process of step 4 of implementation 1, an electrical circuit is prepared on the above substrate.

[0083] 3. Cut the above substrate to form a single packaged ceramic substrate, specifically including the aluminum substrate 11, Bi 2 o 3 Added ZnO pressure-sensitive ceramic film 12, copper / silver double-layer film electrode 2.

[0084] 4. Bond the LED bracket including metal heat sink 14 , lead pin 15 , and molding compound 16 on the above-mentioned substrate with silver glue 13 .

[0085] 5. Bake in the oven for 2 hours at 120 oC. Let cool, and take out when the temperature drops to room temperature.

[0086] 6. Weld the lead pin 15 on the positive and negative electrodes 3 .

[0087] 7. Solder the LED chip 4 to the pin 15 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com