White light LED (Light Emitting Diode) packaged on composite ceramic substrate and preparation method thereof

A technology of composite ceramics and LED chips, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problem that LED power density is difficult to increase, and achieve the effect of simple packaging structure, good toughness, and simplified packaging structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

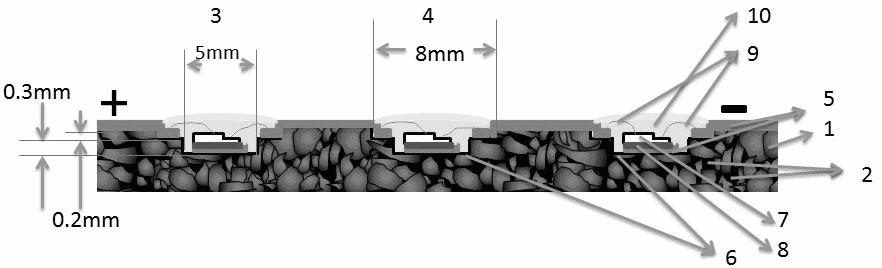

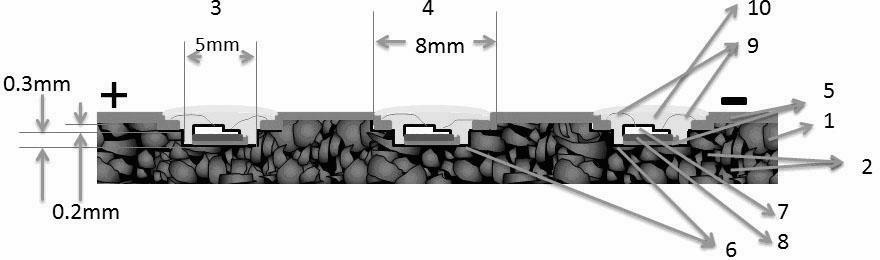

[0044] Example 1 Weighing an appropriate amount of AlCl 3 ·6H 2 O, add an appropriate amount of deionized water, stir and dissolve into a solution, add 1:5 ammonia water at an appropriate temperature of 60 oC, and coprecipitate to form Al(OH) 3 , Filtration and drying can be prepared to obtain alumina powder. Thereafter, press Al 2 o 3 / SiC is a ratio of 4:1. Add nano-silicon carbide powder (silicon carbide can be purchased from the Beijing Institute of Chemical Metallurgy, Chinese Academy of Sciences, with an average diameter of 30nm) to the alumina powder, mix evenly, and make a green body by ball milling and isostatic pressing. , Sintered at 1600-1750 oC in a nitrogen atmospheric pressure furnace. Among them, the isostatic pressure is 80Mpa, and the high-temperature sintering at atmospheric pressure is held for 10 hours. After the temperature drops below 300 oC, the ceramic substrate with a diameter of 3 cm and a thickness of 1.2 mm with 3 ear holes is obtained. The LE...

Embodiment 2

[0053] Example 2 Weigh an appropriate amount of alumina powder and silver oxide powder, according to Al 2 o 3 / AgO at a ratio of 10:1 and mixed evenly, after ball milling, isostatic pressing, making green body, and sintering at 1600-1750 oC in a normal pressure atmosphere furnace. Among them, the isostatic pressure is 100Mpa, and the high-temperature sintering at atmospheric pressure is held for 10 hours. After the temperature drops below 300 oC, the ceramic substrate with a diameter of 3 cm and a thickness of 1.2 mm is obtained with 3 ear holes. The LED was prepared through the same process as in Example 1.

Embodiment 3

[0054] Example 3 Weigh an appropriate amount of alumina powder and aluminum nitride powder, according to Al 2 o 3 / AlN at a ratio of 4:1 and mixed evenly, after ball milling, isostatic pressing, making green body, and sintering at 1600-1750 oC in a normal pressure atmosphere furnace. Among them, the isostatic pressure is 100Mpa, and the high-temperature sintering at atmospheric pressure is held for 10 hours. After the temperature drops below 300 oC, the ceramic substrate with a diameter of 3 cm and a thickness of 1.2 mm is obtained with 3 ear holes. The LED was prepared through the same process as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com