Quantum dot luminescence transparent casting glue composite material

A technology of quantum dot light-emitting and composite materials, applied in the field of quantum dot light-emitting transparent potting compound materials, can solve the problems of low energy conversion efficiency, less red components, and low color rendering index of LED white light, so as to improve the luminous efficiency and Color rendering, simple preparation method, and the effect of optimizing the packaging structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

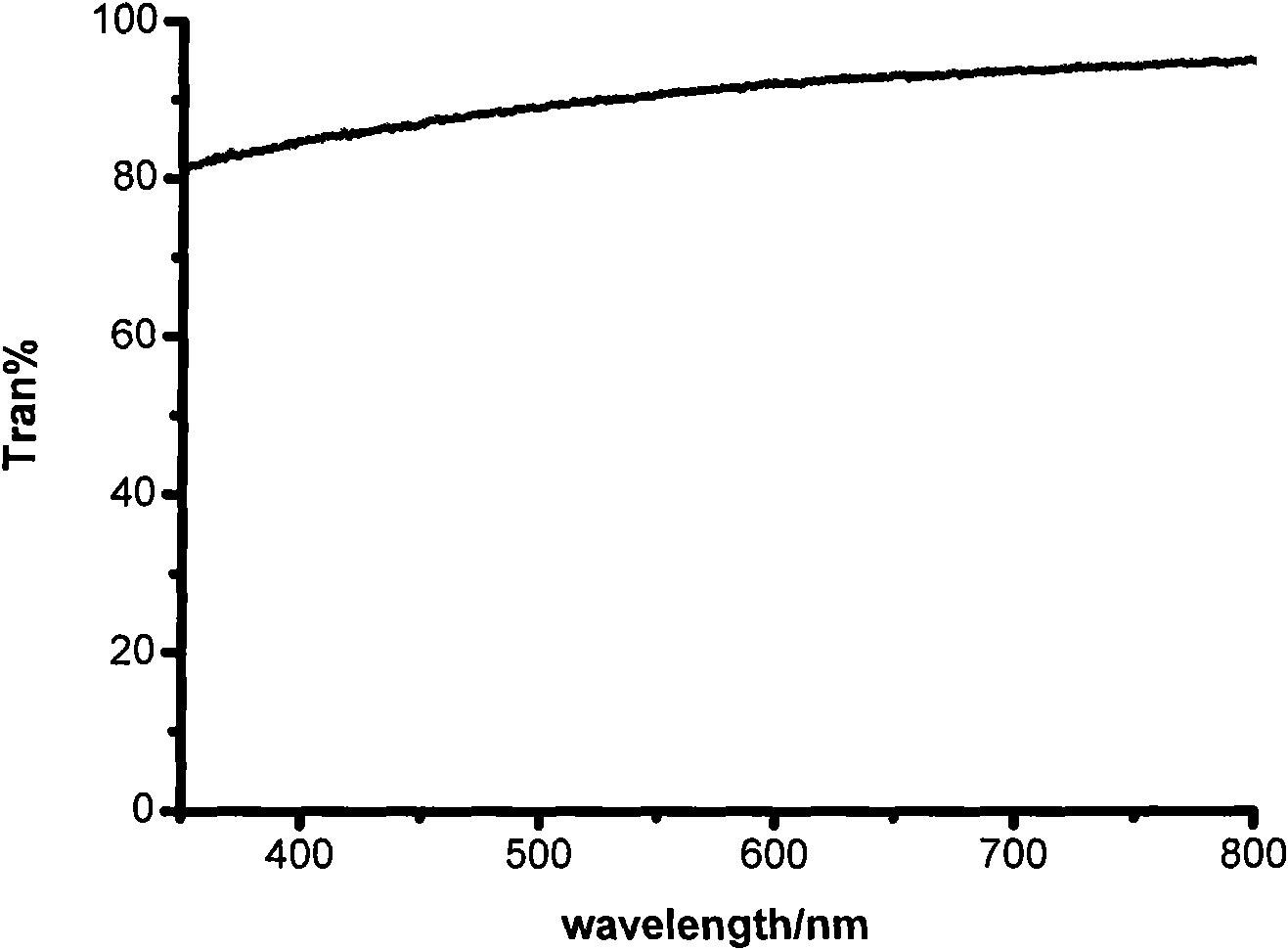

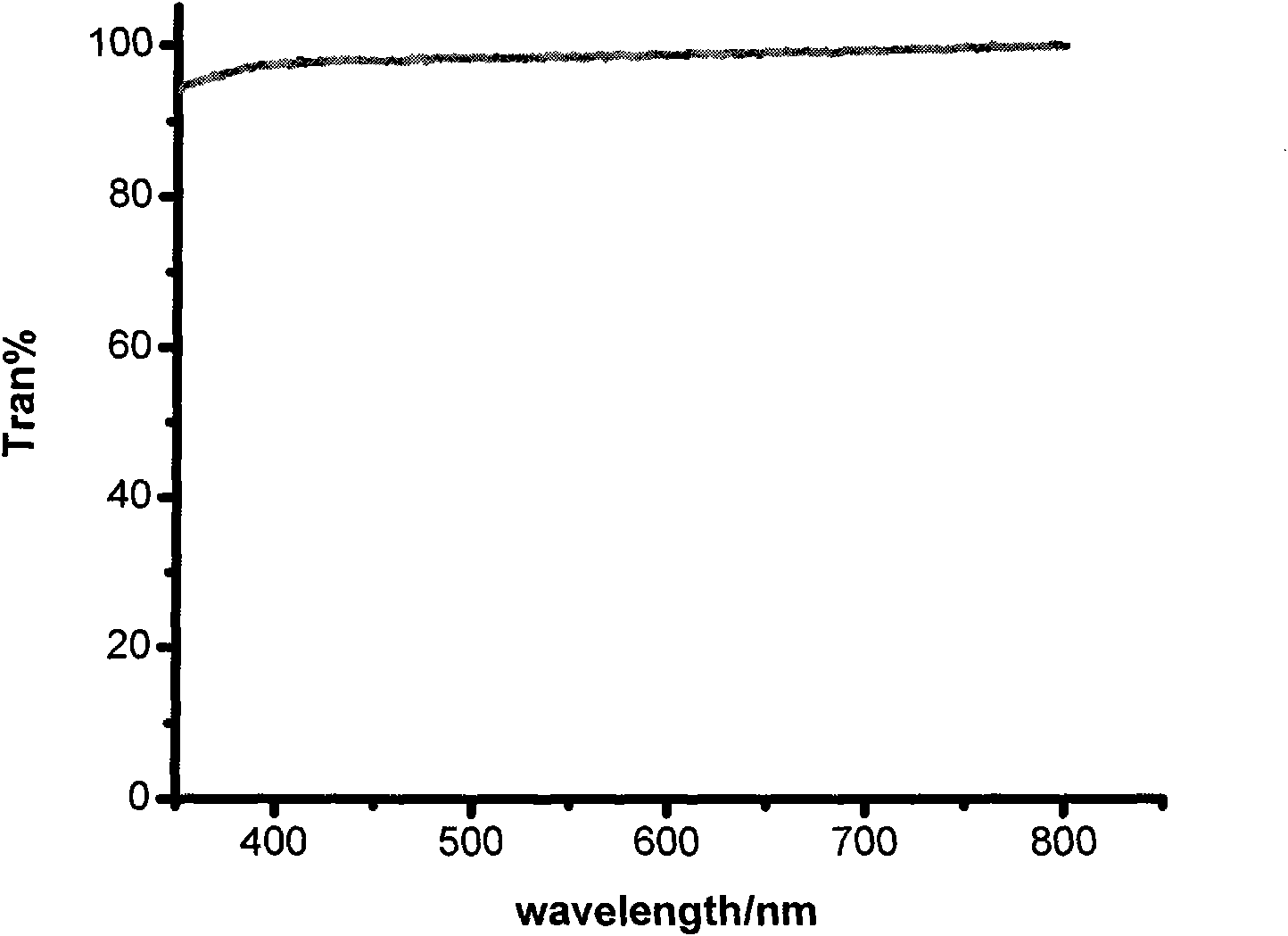

Image

Examples

Embodiment 1

[0023] a. Preparation of quantum dot luminescent materials

[0024] Preparation of ZnO by Sol-Gel Method 2 Quantum dot nanomaterials, 0.75g of zinc nitrate hexahydrate, 2.5mL of analytically pure ethyl orthosilicate, and 0.15g of urea were sequentially added to 50mL of absolute ethanol solution and stirred evenly, and then the pH was adjusted with nitric acid with a concentration of 1M, so that The pH value of the above mixed solution is 3, and a transparent solution is formed after 10 hours of stirring reaction, and after the absolute ethanol in the solution is completely volatilized at room temperature, the formed white substance is dried at 100°C for 2 hours, and finally The prepared material is annealed at a certain temperature between 300 DEG C and 700 DEG C for 3 hours to obtain the ZnO quantum dot nano material.

[0025] b. Surface modification of quantum dot luminescent materials

[0026] Take 5 mg of sodium lauryl sulfate with a purity greater than 95% and dissolve ...

Embodiment 2

[0030] a. Preparation of quantum dot luminescent materials

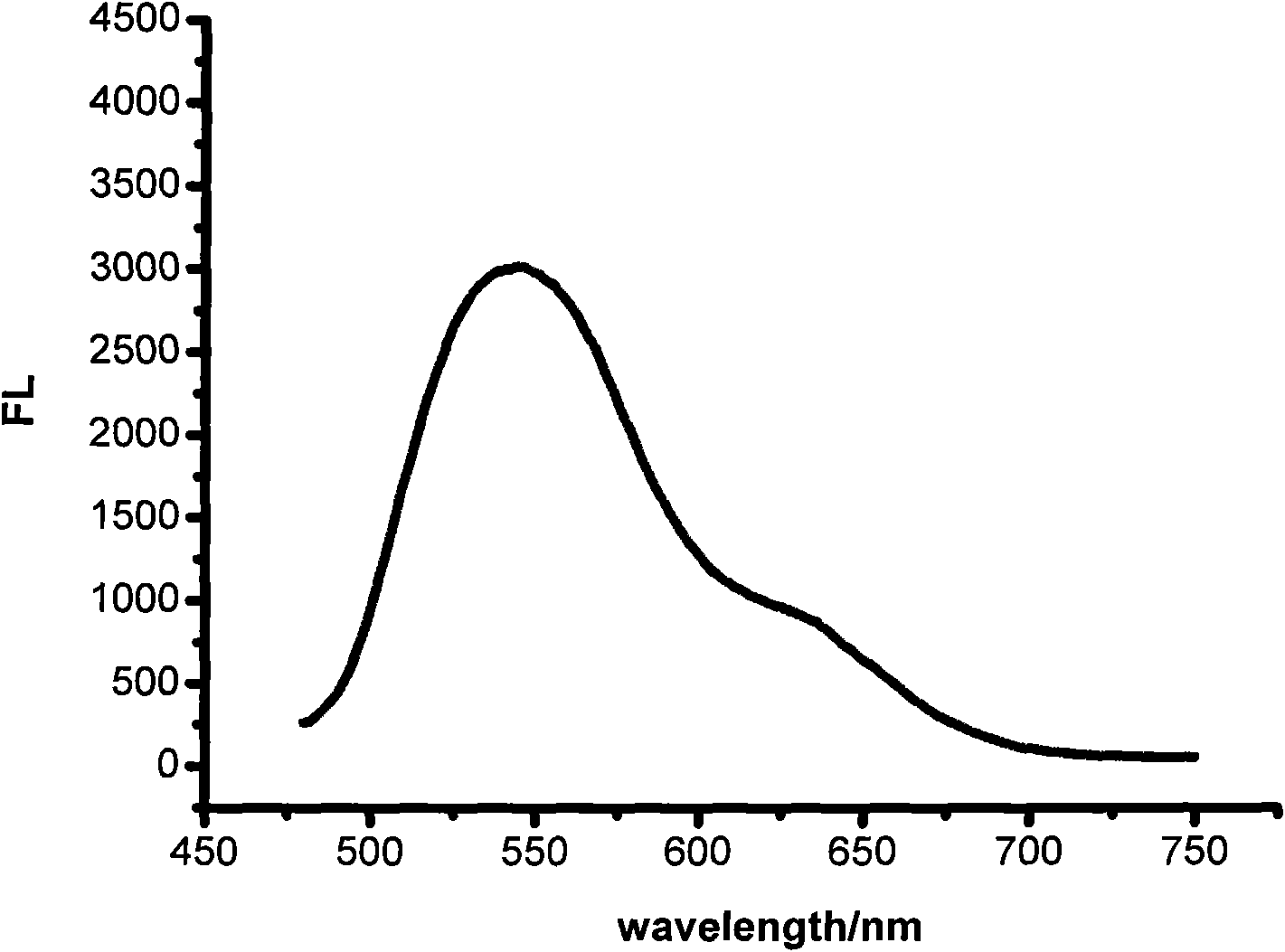

[0031] CdSe-Cu quantum dot nanomaterials were prepared by sol-gel method, and 0.17gCuCl 2 2H 2 O with 0.29gCd(CH 3 COO) 2 2H 2 O was mixed and dissolved into 150 mL of analytically pure N,N-dimethylformamide, and 1.5 mL of analytically pure mercaptoethanol was added, then 1 mL of 20% sodium selenite solution was added dropwise within 5 minutes Slowly add to the above mixed solution, reflux the final solution for 3 hours, dissolve it in absolute ethanol three times, centrifuge, and dry it in a vacuum oven at 80°C for 2 hours to prepare the CdSe-Cu quantum dot luminescent material , the size of its quantum dots is below 10nm, and it can emit white light with a peak value of about 550nm under the excitation of 460nm blue light, and the pressure of the vacuum drying oven is controlled below 200Pa.

[0032] b. Surface modification of quantum dot luminescent materials

[0033] Get CdSe-Cu quantum dot nano material 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com